Website:

OMEGA AIR d.o.o. Ljubljana

Website:

OMEGA AIR d.o.o. Ljubljana

Catalog excerpts

OMEGA AIR: A-Dry - Adsorption compressed air dryer BACKGROUND Compressed air contains contaminants such as water, oil and particulates which must be removed or reduced to the acceptable level based on specific application requirements. ADSORPTION DRYER Typical applications for the adsorption dryers are outdoor installations where the risk of freezing occurs and applications with high quality requirements in terms of air dryness (PDP < +3°C) such as the process air in process industry (food and beverage, pharmaceutical, electronic, chemical, …). Standard ISO 8573-1 specifies air purity/quality classes for these contaminants. Humidity (water vapour content) is expressed in the terms of Pressure Dew Point (PDP) where Dew point is the temperature at which air is 100% saturated with moisture. When the temperature of the air reduces to or below the dew point, condensation will occur. Reduction of water content down to pressure dew point +3°C is usually achieved with refrigerant dryers while for lower pressure dew points adsorption (also called desiccant) dryers are typically used. ADSORPTION Adsorption is a process where specific molecules adhere to the surface of a highly porous solid (adsorbent/desiccant) by electrostatic and molecular forces. The adsorbent is normally formed in sphere form beads. Process of adsorption takes place while air flows through column filled with the beads. Rate of adsorption depends on several factors (type of adsorbent, relative humidity, inlet temperature, contact time, face velocity) and therefore adsorption process is usually set/optimized for every individual application. Heatless adsorption compressed air dryers The most common adsorption dryers are heatless regeneration adsorption dryers due to their simplicity reliability and relatively low investment costs. CONTROLLER Adsorption dryer controller ADC 4.0 is the next generation of electronic controllers for compact heatless adsorption dryers. New version brings more functionality to the controller while maintaining simplicity and low cost. In addition to the more advanced electronic the new interface with LCD display, four interface buttons and three indication LEDs give even more interactivity and information to the user. Controller is suitable for dew point dependent dryer control which can result in significant energy savings. As an option A-DRY dryers can also be delivered with even more powerful Siemens Logo! Controller. Floor mounted version Wall mounted version Convenient brackets allow the dryer to be firmly mounted on the floor as well as on the wall. Wall mounting is possible simply by rotating the bracket for 90°. High quality two layer desiccant bed A-DRY series adsorption dryers are filled with a high quality robust desiccant which results in a stable operation with a low energy input for the regeneration. Primary desiccant is a molecular sieve with an extremely high drying potential. To prevent potential degradation of primary desiccant due to liquid water, bottom part of the column is filled with a water resistant silica gel. Spring fixed desiccant bed Integrated exhaust silencers Removable desiccant column Movement of the desiccant causes abrasion and channeling which results in decrease of the drying efficiency. Therefore every A-DRY column is equipped with a spring which provides constant force on the desiccant bed thus assuring uniform distribution of beads without any movement during operation. Each column contains integrated exhaust silencer for efficient noise reduction due to compressed air pressure release during column switch over process. Only two screws are necessary to release the desiccant column. Replacement of the desiccant media has never been so quick and easy - you save your valuable time and money. Exhaust silencers provide low released compressed air velocities and safe working environment. The columns and the cover sheet metal parts are epoxy powder painted while all the other aluminium parts are anodized to prevent any potential oxidation. Individually controlled valves Heavy duty valve design Compact control blocks To provide optimum control over the complete drying process four high quality electromagnetic valves are used. Individual control of each valve results in column switch-over without any pressure peaks. Coils are spring fixed which assures stable operation even under most difficult conditions (e.g. portable applications, railway, heavy vibrations, …) Design of the membrane is optimised for pressure swing adsorption applications. Due to compact design of upper and lower control block check valves and purge air nozzles are integrated in the robust block which results in a reliable operation and easy replacement during service procedure. Additionally valves are protected by a sheet metal plate. Two manometers positioned on top of the upper control block give reliable information about the pressure inside of each column. In combination with LED indication on the controller manometers are excellent tool for diagnostics. Plastic reinforcement & guiding plate increases lifetime of the membrane and assures reliable operat

Open the catalog to page 1

OMEGA AIR: A-Dry - Adsorption compressed air dryer Operating cycles Easy maintenance Technical data A-DRY dryers can operate in two operating modes based on setting of the controller. Fixed cycle mode Switch over between columns is timer controlled. Due to high quality adsorbent and advanced control method adsorption cycle is extended to 10 minutes resulting in lower amount of switch overs thus lower consumption of compressed air and less wear of vital components. Adsorption = 5 min Regeneration = 4 min Pressure build up = 1 min Due to innovative column design desiccant replacement can be...

Open the catalog to page 2All OMEGA AIR d.o.o. Ljubljana catalogs and technical brochures

-

Catalogue - Product overview

72 Pages

-

Screw compressors MA SD 2-3

2 Pages

-

MA SD 7,5-15 VS /BDK

2 Pages

-

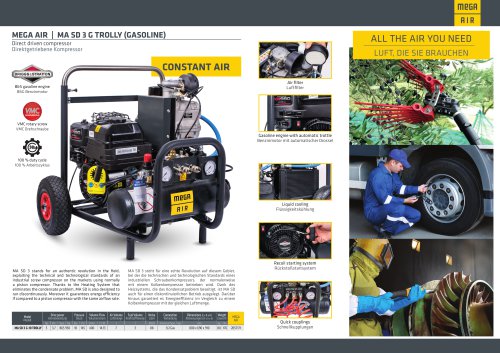

Piston compressors - MEGA AIR

12 Pages

-

Container and Skid units

8 Pages

-

WFIF SERIES

2 Pages

-

WHFIT SERIES

2 Pages

-

MEGA TOOLS

12 Pages

-

MEGA AIR QUALITY OILS

8 Pages

-

CO2-R-DRY series

2 Pages

-

ACW series

1 Pages

-

ACA series

1 Pages

-

RDHP series

2 Pages

-

RDF

2 Pages

-

RDL series

2 Pages

-

RDP series

2 Pages

-

M-DRY series

2 Pages

-

HP-DRY series

2 Pages

-

R-DRY BVL series

2 Pages

-

R-DRY BP series

2 Pages

-

COM-DRY series

2 Pages

-

X-DRY series

2 Pages

-

A-DRY TAC

2 Pages

-

A-DRY BI+BM series

2 Pages

-

PV

2 Pages

-

AIR AND GAS Product overview

2 Pages

-

Compact oxygen generators

2 Pages

-

Compact nitrogen generators

2 Pages

-

SKID based solutions

2 Pages

-

Biogas plants

8 Pages

-

OCI

1 Pages

-

CKL-IHP series

2 Pages

-

SF series

2 Pages

-

WFIW series

2 Pages

-

MSS

2 Pages

-

MDH 400

1 Pages

-

CHI

1 Pages

-

VPG 60

1 Pages

-

FA - flange adapter

1 Pages

-

TD 400M series

1 Pages

-

AOK 50SS

1 Pages

-

EVD series

1 Pages

-

RC-DRY series

2 Pages

-

HPR-DRY series

2 Pages

-

TAC HP series

2 Pages

-

A-CAT series

2 Pages

-

SFH HP

2 Pages

-

TP PED series

2 Pages

-

TP ASME series

1 Pages

-

TP series

1 Pages

-

BS TOWER

1 Pages

-

PETRO-PACK

1 Pages

-

AWS

1 Pages

-

BS 12-3,5

1 Pages

-

AIRWATT series

2 Pages

-

B-AIR plus series

2 Pages

-

OWT

2 Pages

-

OWE/HWE

2 Pages

-

OWB

2 Pages

-

OBE SERIES

2 Pages

-

ECD-B series

2 Pages

-

MDHI 50

1 Pages

-

BF series

2 Pages

-

HPF series

2 Pages

-

AK- assembly kit for filters

1 Pages

-

IHP series

2 Pages

-

PF series

2 Pages

-

EPG 60

1 Pages

-

MDM40

1 Pages

-

OCI

1 Pages

-

AV series

2 Pages

-

SPF series

2 Pages

-

CS /CS SS series

2 Pages

-

SFH /SFH SS series

2 Pages

-

CKL-CHP series

2 Pages

-

MDM60

1 Pages

-

MDH

1 Pages

-

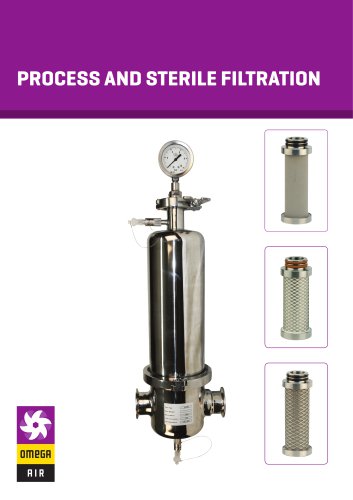

PROCESS AND STERILE FILTRATION

12 Pages

-

SORBEO Adsorbents

2 Pages