Catalog excerpts

n° 8_0086 CHEMICAL NICKEL OMAL S.p.A. Via Ponte Nuovo 11 - 25050 RODENGO SAIANO (BS) ITALY Tel. 030/8900145 r.a. - Fax 030/8900423

Open the catalog to page 1

All data and specifications in this manual may be changed at any time and without prior notification to improve our products. They cannot be considered binding.

Open the catalog to page 2

CHEMICAL NICKEL PLATING Over the past few years electro-less chemical-nickel plating has improved dramatically by reducing the Ni++ ions to Metallic Ni catalytically without using electricity (AUTOCATALYTIC CHEMICAL REDUCTION) thus obtaining plating with excellent properties. OMAL ACTUATORS WITH CHEMICAL NICKEL-PLATING OMAL has always been focused on providing their customers with actuators which could meet the most demanding requirements, be totally reliable and safe even in the most hostile environments. That is the philosophy which has brought OMAL to add a series of chemical-nickel...

Open the catalog to page 3

CORROSION RESISTANCE During salt spray testing chemical nickel features a better resistance than electrolytic nickel thanks to its limited porosity and phosphor content. Corrosion resistance is outstanding in alkaline environment (non-ammoniacal) and with most organic acids in non ventilated environments; it is satisfactory with most inorganic acids and very limited with hydrochloric acid in ventilated environments. The table below shows chemical nickel resistance to corrosion in various compounds at room temperature; the appendix shows the compatibility of chemical nickel plating with...

Open the catalog to page 4

APPENDIX COMPATIBILITY WITH CHEMICAL NICKEL PLATING A – Extremely compatible with chemical nickel plating B – Moderately compatible with chemical nickel plating; less compatible at higher concentrations C – Not particularly compatible with chemical nickel plating due to nickel corrosion and consequent lack of protection SOLUTION Sulfuric acid Hydrogen sulfide Salt water Carbon tetrachloride Toluene Trichloroethylene De-mineralized water Wine Whisky Zinc chloride Acetone Aluminum chloride Aluminum sulfate Formic acid Ammonium chloride Ammonium hydroxide Ammonium nitrate Amyl alcohol Apple...

Open the catalog to page 5

A – Extremely compatible with chemical nickel plating B – Moderately compatible with chemical nickel plating; less compatible at higher concentrations C – Not particularly compatible with chemical nickel plating due to nickel corrosion and consequent lack of protection SOLUTION Crude oil Nitric acid Hydrochloric acid Hydrogen sulfide Sulfuric acid Potassium hydroxide Calcium hydroxide kerosene Copper chloride Copper nitrate Copper sulfate Linseed oil Magnesium chloride Magnesium hydroxide Raw molasses Methyl alcohol Milk Lactic acid Mineral oil Sodium bicarbonate Sodium carbonate Sodium...

Open the catalog to page 6All OMAL Spa catalogs and technical brochures

-

MAGNUM & THOR

7 Pages

-

General Catalogue

592 Pages

-

"EA" ON-OFF rotary type

9 Pages

-

Special ends

21 Pages

-

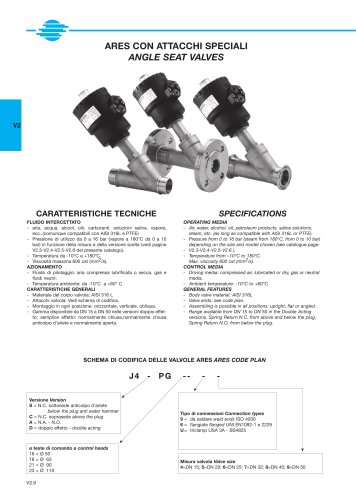

Angle seat valves

33 Pages

-

ITEM 545

7 Pages

-

Pneumatic actuators

6 Pages

-

Heavy Duty spring return

65 Pages

-

Heavy Duty Double acting

29 Pages

-

Pro-Chemie 60

7 Pages

-

Trunnion ball valves Supreme

18 Pages

-

stainless steelANSI 900-1500

13 Pages

-

TFM1600 seats

1 Pages

-

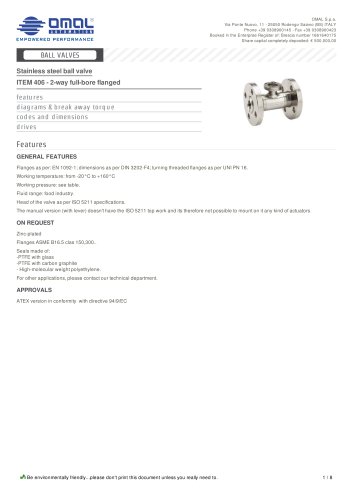

Stainless steel ball valve

11 Pages

-

Hercules

10 Pages

-

Vip - Pneumatic axial valve

7 Pages

-

CONVERSION DA ? SR

4 Pages

-

CONVERSION SR ? DA

4 Pages

-

TRANSMISSION MECHANISM

6 Pages

-

OMAL ACTUATORS TESTING

4 Pages

-

TWO STAGE

2 Pages

-

ELECTRICAL ACTUATOR EA

6 Pages

-

ELECTRICAL ACTUATOR AE

6 Pages

-

DOUBLE ACTING "DA" AISI 316

2 Pages

-

DOUBLE ACTING "DA"

4 Pages

-

ART. 460-461

4 Pages

-

ART. 420

4 Pages

-

V415 ART. 415

4 Pages

-

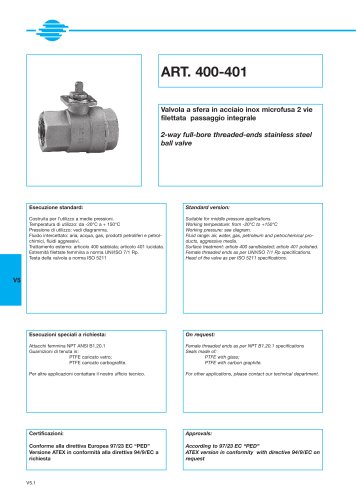

ART. 400-401

4 Pages

-

ART. 216

4 Pages

-

ART. 160-161

4 Pages

-

ART. 153

4 Pages

-

ART. 116

4 Pages

-

ART. 113

4 Pages

-

ART. 101

4 Pages

-

ART. 100

4 Pages

-

Pneumatic axial valve

8 Pages

-

ARES WITH MANUAL DRIVE

2 Pages

Archived catalogs

-

OMAL - General Catalogue (en,it)

274 Pages