Catalog excerpts

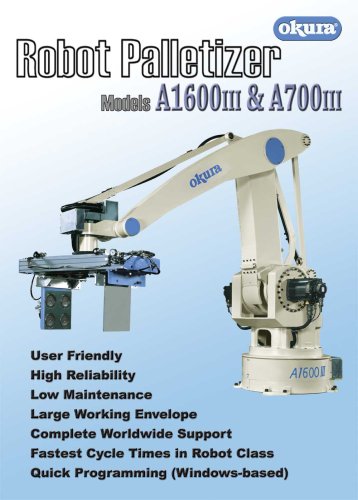

User Friendly High Reliability Low Maintenance Large Working Envelope Complte Worldwide Support Fastest Cycle Times in Robot Class Quck Programm诮ng (Windows-based) >l/600l.l

Open the catalog to page 1

AlSOOm flOSOT PALLTIZãfl i L /4/60M ROBOT SPECIFICATIONS Model AI6OO111 Motion Svstem Multi-Articulated, Polar Coordinate Syslem Load Capacitv 140 kg (including end ctector weight) Degree of Opration Range 4 axes (R, D. 0. T axes) R axes 360° D axes 2300mm O axes 1518mm T axes 440° Handling Rate 1600 cyclcs/hour MAX * Slacking capacity varies depending on ihe layout, multiple gripping and other conditions. 懲ccuracv Repeated stop position accuracy ± 1 mm Robol Weight 1 !(>() ky (wiihout end effeetor) Pneumatic Consumption 180 f/min (ANR) When cquipped wiih a pallet dispenser 30X1 (/min (ANR)...

Open the catalog to page 2

A7Q0IH ROBOT SPECIFICATIONS Model A700iii Motion System Multi-Articulated, Polar Coordinate System Load Capacity 140 kg (including end effector weight) Degrce of Opration Range 4 axes(R, D, 0, Taxes) R axes 360° D axes 2300mm O axes 1750mm T axes 440° Handling Rate 700 cycles/hour MAX. * Stacking eapacily varies dcpending on the layout. multiple gripping and other conditions. Accuracv Repeated stopj>osition accuracy ± Imm Robot Weiglit 1250 kg (without end effector) Pneumatic Consumpton 180 (/min (ANR) Whcn cquippcd wilh a pallct dispenser 300 (/min (ANR) Ambicnt Temp 0-40°C Relative...

Open the catalog to page 3

APPLICATION EXAMPLES The Al 600m W version handles weights of up to 300 kg. Idal for full layer palletizing to acheive high capacity!! The Al600m and A700m robot palletizers feature up to360°of movement on their rotational axis, allowing palletizing of up to 6 pallets by a single robot palletizer! 3UILT-IN STAC Kl NG PATTHRNS CASE Column pattern (Columnarsta cking) Interlo cking pattern Interlocking pattern Interloddng pattern withgaps Pinwheel pattern Spcial pattern BAG I nte ri o dci n g p atte m I nt erl o cki n g pattern w ith g a ps I nterl o cki n g patter n w ith g a ps Pi nw h ee I...

Open the catalog to page 4

CONTROL PANEL SPEClf JCATfONS CE Versions JIS Versions Model RC 715 (A 1600m) RC 725 (A 700tu) RC 712 (A 1600m) RC 722 (A 700m) Dimension 900w * 640° 1250H mm 800w ' 640° Օ 1150M mm Weiqht 250 Kq 210 Kq 140 Kq 165 Kq Power Robot 6.5kVA Robot 2.5kVA Robot 6.5kVA Robot2.5kVA AC380/400/415V (Transformer) ±5% 50/60Hz, Three Phase AC200V/220V ±5% 50/60Hz, Three Phase Ambient Temp 0-40°C Relative Humidity 35-85% f r 111 The Okura robot palletizer control panel can be connecte! to any Local Area Network (optional), such as a client's production control computer Systems, to enable Real Time...

Open the catalog to page 5

ROBOT PALLHTJ2HR STANDARD LAYOUTS Automatic Pallet Supply Layouts PO 16 One Pallet LayoutNo. POU 11 One Pallet Layout No. P02111 One Pallet Layout No. P03111 Two Pallets LayoutNo. P05122 Floor Placement Layouts Two Pallets LayoutNo. P08122 Two Pallets Layout No. P10212 , WMIA70C ngfl ■'16001 J One Pallet LayoutNo. FO1101 Two Pallets Layout No. F03102 Two Pallets LayoutNo. F05102 Abbreviations SC = Station Conveyor CR = Control Panel PD = Pallet Dispenser PC = Pallet Conveyor DC = Discharge Conveyor Two Pallets Layout No. F07202 Three Pallets Layout No. F06103

Open the catalog to page 6

SOFTWARE SPECIFICATIONS mi 0XPA-Qm2 Palletizing Software -OfflineTeadiing Teaching data can be inputfrom another location, reducing the amount of set-up time required. -User-friendlyandQuickOperability The optimal palletizing pattern is automatically selected when product dimensions and conditions of the peripheral equipment are input. -FlexibleTeadiing OXPA has the capability to teach Okura robot palletizers in terms of multi-picks, row picksand others.Thisexpands on the range of teaching applicabilit and displaysour product flexibility. Robot P*tl«ci**r Convoiter 1■ Input of Product...

Open the catalog to page 7

Why Okura? okura In business since 1927 More than 3,500 installations world-wide Gripper designs for a wde range of applications Total maintenance and after-sales service We provide SOLUTIONS, not just products. Company Information Japan Okura Yusoki Co. Ltd 900 Furuouchi Noguchi-cho Kakogawa Hyogo Japan 675-8675 Tel: +81 794 26 1009 Fax: +81 794 26 1184 Email: admin@okurayusoki.co.jp Website: www.okurayusoki.co.jp Singapore Okura Flexible Automation Systems Pte Ltd (OFAS) 211 Henderson Road #08-04 Henderson Industrial Park Singapore 159552 Tel: +65 6276 1711 Fax: +65 6276 7211 Email:...

Open the catalog to page 8Archived catalogs

-

robot palletizer

8 Pages