Website:

OKS Spezialschmierstoffe GmbH

Website:

OKS Spezialschmierstoffe GmbH

Group: Freudenberg

Catalog excerpts

OKS Speciality lubricants for www.oks-germany.com Rolling bearing lubrication INNO VAT I V E P RO DUCT S F O R P R OD U C TION AND M AI NT E NANCE T E CHNO L O G Y Speciality Lubricants Maintenance Products

Open the catalog to page 1

Right rolling bearing lubrication reduces machine failures through bearing damage … Functional principle and types of a rolling bearing Decision criteria for grease or oil lubrication Rolling bearings allow friction-reduced rotary move- Grease lubrication is used at approximately 90 % of ments between various machine components. In engi- all rolling bearings. The main advantages of grease neering, rolling bearings are therefore used, amongst others, to guide and support shafts and axles. Rolling bearings are based on the principle of rolling friction: Good support for sealing of the bearing...

Open the catalog to page 2

… and increases the operational reliability Characteristics for selecting a rolling bearing grease The choice of a rolling bearing grease depends on the The SKF-Emcor process is used to assess the corro- design of the rolling bearing and the material of the sion protection properties of rolling bearing greases. rolling bearing cage (metal or plastics) as well as the In the process water is added to the grease and conditions of use and application, such as the appli- examined for corrosion self-aligning ball bearings cation temperature, speed range, pressure load and with defined running...

Open the catalog to page 3

Over 150 high-performance products from one supplier OKS – Quality made in Germany The OKS brand stands for high-performance products for reducing friction, wear and corrosion. The success of OKS, which has continued uninterrupted for 40 years, is decisively shaped by the high quality and reliability of our products developed and produced by experience experts at our headquarters in Maisach near Munich with modern testing systems and equipment. OKS – your professional partner Our high tribologic expertise, our comprehensive technical service, smooth availability and our innovative...

Open the catalog to page 4

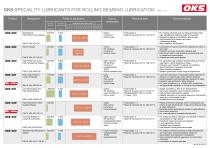

OKS SPECIALITY LUBRICANTS FOR ROLLING BEARING LUBRICATION Page 1 of 2 Product Designation Fields of application Colour, Technical data Characterisation DN factor Four-ball Temperature application range (°C) OKs 402 Ball-Bearing High-Performance Grease 2,000I • beige • NLGI grade: 2 • mineral oil • Base oil viscosity (40 °C): 110 mm2/s • lithium soap -25 °C to +80 °C • brown • NLGI grade: 1-2 • EP additives • Base oil viscosity (40 °C): 100 mm2/s • mineral oil • calcium soap OKs 404 High-Performance and High-Temperature Grease 2,800I -30 °C to +150 °C •...

Open the catalog to page 5

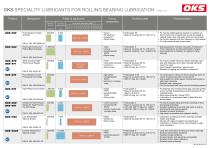

OKS SPECIALITY LUBRICANTS FOR ROLLING BEARING LUBRICATION Designation Fluid Grease for Gears, synthetic Technical data yy brown yy additives EP yy polyglycol yy lithium soap yy NLGI grade: 00 yy Base oil viscosity (40 °C): 120 mm2/s yyor heavily loaded gearing exposed to weather outF yy black yy carbon yyolyalphaolefin p yy NLGI grade: 2 yy Base oil viscosity (40 °C): 150 mm2/s yy Specific resistivity: max. 10,000 Ω*cm yypecial grease for long-term lubrication of rolling and S Electrically Conductive Rolling Bearing Grease White Universal HighPerformance Grease Fluid Grease for Food...

Open the catalog to page 6All OKS Spezialschmierstoffe GmbH catalogs and technical brochures

-

TRIBOLOGY BASIC KNOWLEDGE

24 Pages

-

OKS General Catalog

56 Pages

-

OKS 2670

2 Pages

-

OKS 2681

2 Pages

-

OKS 2611

2 Pages

-

OKS 2200

2 Pages

-

OKS 601

2 Pages

-

OKS 481

2 Pages

-

OKS 471

2 Pages

-

OKS 479

2 Pages

-

OKS 451

2 Pages

-

OKS 480

2 Pages

-

OKS Airspray System

6 Pages

-

Mox-Active

2 Pages

-

Folder Chronolube

6 Pages

-

OKS chain lubrication

6 Pages

-

OKS 2631

2 Pages

-

OKS 3570

2 Pages

-

OKS 3710

2 Pages

-

OKS Image Brochure

8 Pages