Catalog excerpts

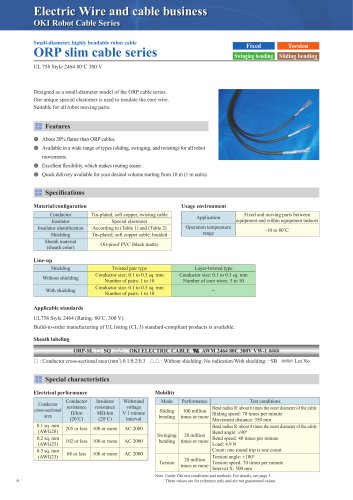

Electric Wire and cable business OKI Robot Cable Series Small-diameter, highly bendable robot cable ORP slim cable series Swinging bending Sliding bending Designed as a small-diameter model of the ORP cable series. Our unique special elastomer is used to insulate the core wire. Suitable for all robot moving parts. Features ● About 20% flatter than ORP cables. ● Available in a wide range of types (sliding, swinging, and twisting) for all robot movements. ● Excellent flexibility, which makes routing easier. ● Quick delivery available for your desired volume starting from 10 m (1 m units). Specifications Material/configuration Conductor Insulator Insulator identification Shielding Sheath material (sheath color) Usage environment Tin-plated, soft copper, twisting cable Special elastomer According to (Table 1) and (Table 2) Tin-plated, soft copper cable; braided Fixed and moving parts between equipment and within equipment indoors Operation temperature range Oil-proof PVC (black matte) Line-up Shielding Without shielding With shielding Twisted pair type Conductor size: 0.1 to 0.3 sq. mm Number of pairs: 1 to 10 Conductor size: 0.1 to 0.3 sq. mm Number of pairs: 1 to 10 Layer-twisted type Conductor size: 0.1 to 0.3 sq. mm Number of core wires: 3 to 10 – Applicable standards UL758 Style 2464 (Rating: 80˚C, 300 V) Build-to-order manufacturing of UL listing (CL 3) standard-compliant products is available. Sheath labeling ORP-SL □ SQ △△ □ : Conductor cross-sectional area (mm ) 0.1/0.2/0.3 △△ : Without shielding: No indication/With shielding: −SB ####: Lot No. Special characteristics Electrical performance Conductor Conductor resistance cross-sectional Ω/km area (20˚C) 0.1 sq. mm 205 or less (AWG28) 0.2 sq. mm 102 or less (AWG25) 0.3 sq. mm 68 or less (AWG23) Mobility Insulator resistance MΩ-km (20˚C) Withstand voltage V∙1 minute interval Test conditions Bend radius R: about 6 times the outer diameter of the cable 100 million Sliding Sliding speed: 70 times per minute bending times or more Movement distance: 350 mm Bend radius R: about 8 times the outer diameter of the cable Bend angle: ±90° Swinging 20 million Bend speed: 40 times per minute bending times or more Load: 4.9 N Count: one round trip is one count Torsion angle: ±180° 20 million Torsion Torsion speed: 70 times per minute times or more Interval X: 500 mm Note. U nder Oki test conditions and methods. For details, see page 3. These values are for reference o

Open the catalog to page 1

Line-up Twisted pair type Display of product name ● Without shielding: ORP-SL (1) SQ × (2) P (2464) ● With shielding: ORP-SL (1) SQ × (2) P (SB) (2464) (1): Conductor sq. mm (mm2) (See the chart below.) Without shielding Cross-section view (example) *The permitted electric current value is calculated with a straight installation in air. It is not a guaranteed value. Pair twist wire Without shielding With shielding With shielding Pair twist wire Pair twist wire Braided shielding (Table 1) Wire-pair configuration table Corresponding no. Insulation body color No.1 core wire No.2 core wire...

Open the catalog to page 2All Oki Electric Cable catalogs and technical brochures

-

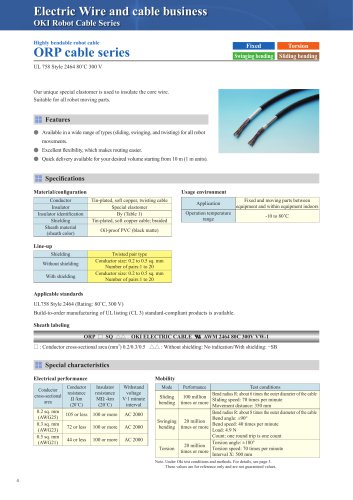

ORP

2 Pages

-

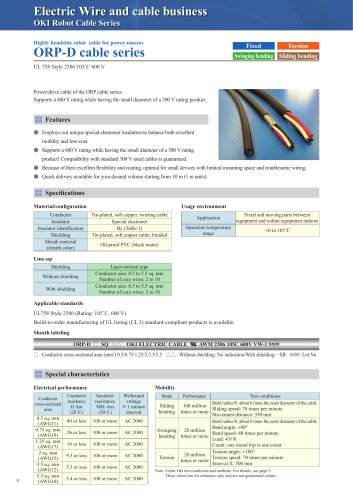

ORP-D

2 Pages

-

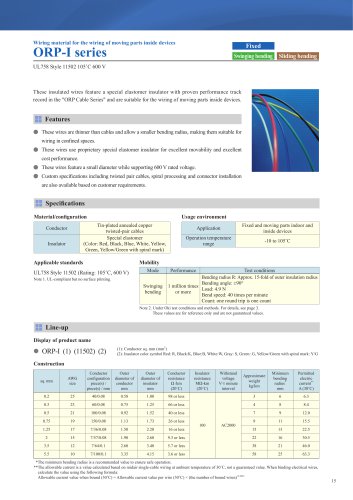

ORP-I

1 Pages

-

OS-UZ wire

2 Pages

-

Cool Staff

4 Pages

-

OB-PZN wire

1 Pages

-

OS-UZ wire

1 Pages

-

OKI Camera Link Cable

4 Pages