Website:

oelheld

Website:

oelheld

Catalog excerpts

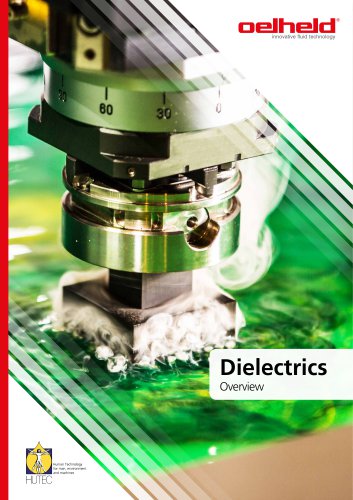

Dielectrics Overview

Open the catalog to page 1

Philipp and Martin Storr • Managing Directors Your partner for cooling lubricants oelheld is a medium-sized company, which has more than 130 years of tradition and experience. Since the foundation in 1887 by Carl Christian Held, oelheld has become an established specialist for lubricants. Partnerships, research, and human resources technology have grown as a valuable tradition of which we are proud of. Numerous customers and machine manufacturers along with national and international universities have partnered with us to develop high quality lubricants. Through this cooperation we are able...

Open the catalog to page 2

Human Technology Innovations for man, environment and machines Hutec is our main focus in the development and production of our products. It is also our mission statement in our use of resources and at oelheld always presence. What does this mean? • REACH requirements are fulfilled • Skin reviews and approvals available for most products • Low emission and aromatics free / low aromatic products • Products free of heavy metal • State-of-the-art production facilities • Environmentally friendly production processes • Products are tested for compatibility with machine components •...

Open the catalog to page 3

The right dielectric for every machine Spark erosion is a modern, metal-removing machining process suitable for all conductive materials. The advantages over machining in high-precision and demanding machining tasks are obvious: It is suitable for all common materials and even complicated geometric shapes can be manufactured. We distinguish between four procedures: Wire erosion, die-sinking erosion, fast-hole erosion and rotary erosion. The spark erosion process takes place in a mainly non-conductive liquid, the dielectric. The tasks of the dielectric are ionization, isolation, cooling and...

Open the catalog to page 4

Your advantages when using our dielectrics Odorless Good filterability Long service life of the dielectric Fast processing Lowest electrode wear Low evaporation Excellent surface qualities Conclusion By choosing the right dielectric, you will not only save time and worries, but also money.

Open the catalog to page 5

Manufacturer Approval: Our products are specifically designed for use with: Machine Manufacturer agema Germany® SARIX 3D MICRO EDM MACHINING

Open the catalog to page 6

High-performance dielectric for EDM die-sinking machines High-performance dielectrics of the IonoPlus IME series are suitable for all requirements during die-sinking. The almost odorless and green dielectric fulfills all requirements from finishing to roughing machining. Using a sophisticated production method, the synthetic product is manufactured in a special blending process. The IonoPlus series does not fall under the operational safety regulations and can be easily filtered with all common filtration systems. Leading machine manufacturers have adapted their generator technology to...

Open the catalog to page 7

IME series Dielectric for EDM die-sinking machines The dielectrics of the IME series have been tested in extensive trials and have proven to be effective in practice for decades. The series is explicitly recommended by leading manufacturers of electrical discharge machines. IME dielectrics have the highest dielectric strength, are clear and almost odorless. Their color does not change during erosion. They reach the purity level of pharmaceutical white oils and are practically free of aromatic compounds. Whether in rough cut applications or for use in fine operations, the dielectric must...

Open the catalog to page 8

EcoSpark 105 Dielectric for EDM die-sinking machines EcoSpark provides an efficient EDM process and combines a high removal volume with low electrode wear. This guarantees a wide range of applications from precision machining to heavy roughing work with high generator power. It is particularly suitable for applications where a minimum flash point of 100 degrees Celcius is required. In addition, the high boiling point significantly reduces steam formation during the spark ignition process. Filtration is easily possible with all filters commonly used in spark erosion. Your advantages: • High...

Open the catalog to page 9

lonoFil series Dielectric especially for wire eroding Cobalt leaching is a problem that is difficult to get under control, especially when machining carbide. This is why oelheld, together with leading companies in the erosion industry and the University of Leuven (Belgium), has decided on a research project to develop a hydrocarbon-based dielectric that is directly adapted to wire cutting technology. The result is IonoFil. Particularly the service life of carbide punches can be enormously extended by eliminating cobalt leaching. This development makes costly and time-consuming deionization...

Open the catalog to page 10

lonoGrind series Dielectric for rotary erosion and grinding Innovative technology makes one out of two: grinding and rotary eroding in one machine. This saves time and money. That's why oelheld developed a fluid especially adapted to this process: lonoGrind. lonoGrind is a multifunctional fluid that is equally suitable for spark erosion and as a grinding oil. It was designed for use in combination machines (two in one) and combines the advantages of a high-performance dielectric for the extremely high removal rate and surface quality with a low-foaming and low-evaporation grinding oil....

Open the catalog to page 11

lonoVit S Dielectric for EDM fast hole drilling lonoVit S is a high-performance dielectric for economical and fast operation with an electrode diameter starting at 0,5 mm (0,0196"). It is also suitable for machining aluminium. Workpieces made of ferrous metals are temporarily protected from corrosion. lonoVit S is a ready-to-use product, so mixing is not required. The concentration is determined by means of a hand-held retractometer and is 7,0% Brix. Your advantages: • Temporary corrosion protection • No cobalt leaching • Free of heavy metals and chlorine • No foam formation • No machine...

Open the catalog to page 12

EDM fast hole drilling machines IonoVit 0 Dielectric for EDM fast hole drilling This water-based product with proper additives guarantees the production of reproducible and high-quality drillings for electrode diameters starting from 0,1 mm. IonoVit 0 is a ready-to-use product, so mixing is not necessary. The Brix value is in a range of 5% – 7%. A dielectric aggregate (water treatment) is required which, in combination with a mixed resin cartridge, ensures good quality and keeps the water conductance at less than 10 uS/cm. If the water conductance increases, the mixed resin cartridge must...

Open the catalog to page 13All Oelheld catalogs and technical brochures

-

DiaGrind

8 Pages

-

Water-soluble cooling lubricants

20 Pages

-

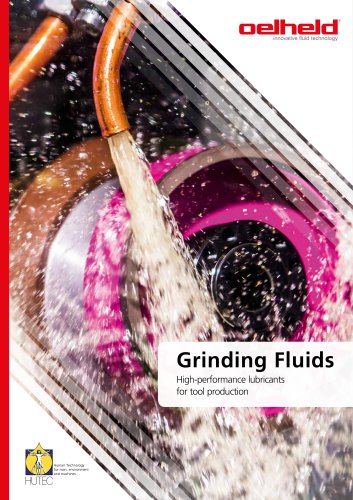

Grinding Fluids

20 Pages