Catalog excerpts

GPM – Glass thickness profiler Highly accurate automatic thickness profile measurement for thin glasses Fields of use The glass thickness profiler GPM has the function to execute a fast and precise determination of the thickness profile of flat glass samples or another transparent material with a thickness range from 30µm to 700µm (option with sensor type 1) and width to 1200mm. The measuring point distance of the profile measurement can be varied over a micro-step-controlled positioning steering between 0.1mm and 1mm. The measured value accommodation for a scanning point takes place with the help of a special hardware module for image processing algorithms within 40 ms. The entire measuring time for a sample results thus as product from the sample width which has to be measured, the measuring point distance and the measuring time per measuring point. Glass thickness profiler (max. 1200 mm) The heart of the measuring position forms a special Sensor(àCAS), which operates on the basis of LASERtriangulation on planparallel glass substrates. The sensor is again coupled with the control computer with the module for the fast image processing and this. Optionally the device can be equipped also with several sensors for different measuring range arises thus as product from the sample width which can be measured, the measuring point distance and gate time per measuring point. The entire measuring machine is controlled with an IBMcompatible PC with WINDOWS95-operating system. Over one in this computer integrated Frame Grabber plug-in card can be observed the condition on the basis a live video image. Optionally also the picture of the Frame Grabbers (under evasion of the fast image processing module) can be used for the direct calculation of the measured values in the control computer, then however with lower measuring speed. OEG GmbH, Wildbahn 8b, D-15236 Frankfurt(O.), Tel.: +49 335 5213 894, Fax: -896 Internet: http://www.oeg-messtechnik.

Open the catalog to page 1

The sample is positioned for the measurement on an adjusted hard stone plate. In order to be able to measure also very thin, foil-like specimen, a defined positioning of the sample is realized during the measuring process by a controllable pneumatically regulated pinch rollers. The measured values for the sample thickness are displayed during the measuring process in realtime in a diagram. After the termination of the measuring process tabulated values are available for the maximum value, minimum value, arithmetic average value, peak to Valley value and the standard deviation. These numeric...

Open the catalog to page 2All OEG catalogs and technical brochures

-

RTM

2 Pages

-

ELCOWIN & ELCOLEVEL

2 Pages

-

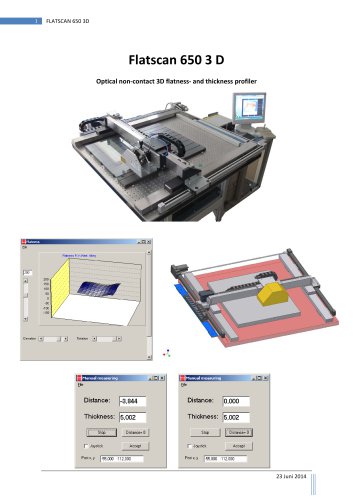

Flatscan 650 3D

7 Pages

-

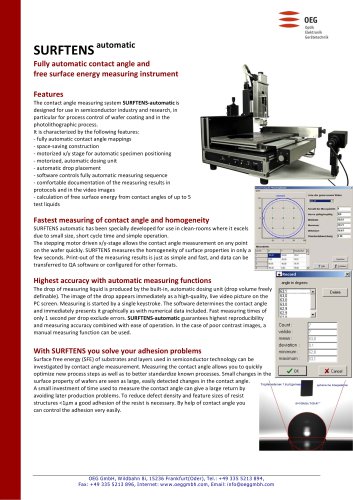

SURFTENS automatic

2 Pages

-

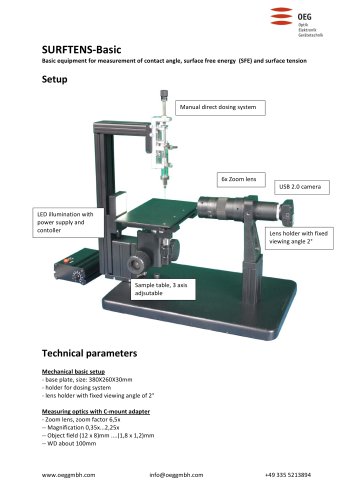

SURFTENS‐Basic

2 Pages

-

OPTICAL HEIGHT GAUGE OHM 150

2 Pages

-

MTF Master 200

2 Pages