Catalog excerpts

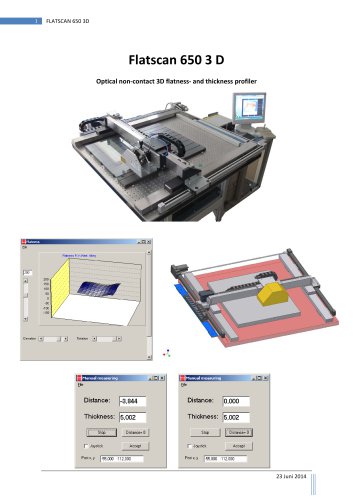

1. The measurement principle The device Flatscan 650 can be used for measuring the thickness of glass and the flatness of surfaces. Measuring range of the sensor: Thickness: 1.5 mm to 5mm resolution: 0.001mm Flatness: up to 1mm resolution: 0.001mm Measuring range: portal facility: X axis: 550mm Y axis: 650mm Fig. 1: Construction of the sensor CAS 45 The thickness of glass and the flatness are measured on the basis of a trigonometric principle. A laser line is projected near the glass surface. ...

Open the catalog to page 2

The position of the first line corresponds to the distance between the glass plate and the CAS sensor. The distance between the line images is proportional to the glass thickness. The proportionality factor is determined with the help of a special calibration method. (chapter10). Attention: The calibration value for measuring the thickness depends on the refractive index of the glass. If precise absolute values of the glass thickness are required, a re‐calibration is necessary for every sort of glass. However, if only small deviations in the glass thickness are ...

Open the catalog to page 3

Attention: The breadboard lies on the vibration dampers without being fixed. Its own weight guarantees the necessary stability. Placing the samples On the breadboard there are slid steel shafts (H6) which can be positioned in any way and are fixed with the help of some magnetic sticks. The shafts should be arranged symmetrically to the width of the glass plates in a distance corresponding to about 75% of the width of the glass plate. Thus the plate’s bending caused by its own weight can be reduced significantly. ...

Open the catalog to page 4

Pneumatics There is only one interface. Please use a plastic pressure hose of a diameter of 6 mm. 4. Manual measurement It is the easiest form of measurement and is generally used for checking the functions and the adjustment. With the joystick, any position can be chosen. Then the thickness and the distance are shown. The setting “Distance=0” sets the distance value onto zero (fig.: 5). If a measurement is made at another position, the distance value refers to the zero position. This measurement function is the basis for automatic measurements. Please ...

Open the catalog to page 5

Fig. 6: First window for the automatic measurement The form shows the look of the measurement pattern, the dimensions of the sample and which mathematic operations should be used for analysing the measurement results. The window can only be edited in the service mode (chapter 9). A sensible file must be loaded which contains the prepared measurement task corresponding to the sample. The buttons are active. They can be used to check if the measurement template is correct and if the sample strikes the stops. If everything is okay, click on “Accept ...

Open the catalog to page 6

Flatness diagram, thickness diagram Here you can call up simple graphics for just measured samples. The graphics can be copied, printed and saved. Please consider that measurement values are saved, no bitmaps. Earlier saved measurement values can be loaded up and displayed. Fig. 12: Example of a flatness graphic Attention: If there are very many measurement values, the data set is reduced onto maximally 100 x 100 measurement values with the help of an interpolation method. The same applies to saving the data. OEG GmbH Wild

Open the catalog to page 7All OEG catalogs and technical brochures

-

RTM

2 Pages

-

ELCOWIN & ELCOLEVEL

2 Pages

-

GPM2

2 Pages

-

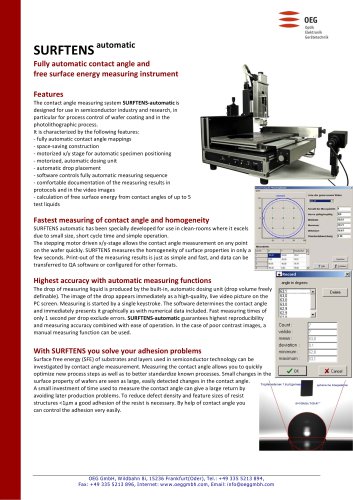

SURFTENS automatic

2 Pages

-

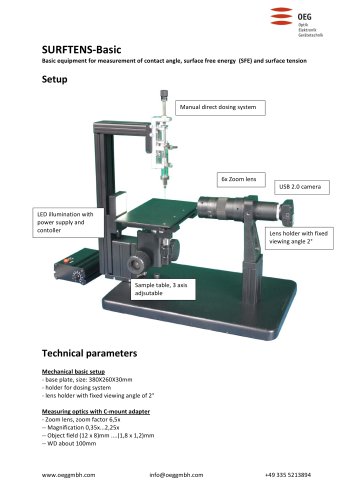

SURFTENS‐Basic

2 Pages

-

OPTICAL HEIGHT GAUGE OHM 150

2 Pages

-

MTF Master 200

2 Pages