Website:

NYLATRON

Website:

NYLATRON

Catalog excerpts

Stock shapes Plastics used in semiconductor technology

Open the catalog to page 1

4 Plastics in application: wafer processing cycle 6 Typical applications in the semiconductor industry 7 Product portfolio 8 Special materials for CMP processes 0 Technical data for CMP applications 1 14 Application examples 5 Frequently asked questions: CMP 1 6 Special materials for further semiconductor processes 1 8 Special materials for back-end applications 1 2 0 Technical data for back-end applications 22 Application examples 2 3 Frequently asked questions: back-end applications 24 Quality management 25 Traceability 26 Material standard values In many areas of industry technical...

Open the catalog to page 2

Plastics in application: wafer processing cycle Many of the process stages involved in semiconductor production require components made of highly qualified materials. Their specific properties, including material purity, resistance to chemicals and good dimensional stability even at high temperatures make high performance plastics from Ensinger ideally suited for the manufacture and processing of wafers. 1. Chemical Mechanical Planarization (CMP) During these processing stages, plastics with good chemical resistance and wear properties such as TECATRON CMP, TECAPEEK CMP, TECADUR PET CMP and...

Open the catalog to page 3

Typical applications of technical plastics in the semiconductor industry TECAFLON PVDF TECAFLON PTFE We offer a wide spectrum of high-performance and engineering materials for applications in the semiconductor industry. Potential applications are in front-end processes such as silicon manufacturing, plasma etching, photolithography, CMP and wafer cleaning, but also in back-end processes such as chip handling and device testing and much more. Insert for spring contacts Test sockets for chips e Contact sockets Chip carriers Vacuum tweezers Heat exchangers Wafer carrier Retaining rings Chip...

Open the catalog to page 4

Special materials for CMP processes Ensinger offers a broad and specialized portfolio for CMP applications: >>TECATRON CMP (PPS) >>TECATRON SE (PPS) >>TECAPEEK CMP PEEK) >>TECAPEEK SE (PEEK) >>TECANAT CMP (PC) >>TECADUR PET CMP (PET) Function: The Chemical Mechanical Planarization (CMP) process is one of the key steps in silicone wafer production. With the migration towards larger wafer sizes, smaller chips with narrower line widths and feature sizes, engineers are always searching for new materials to meet their needs. Therefore CMP applications require an outstanding product performance...

Open the catalog to page 5

Technical data for CMP applications CMP applications require products with superior performance regarding various aspects. Ensinger CMP grades have been thoroughly tested for quality, wear lifetime and several other key attributes. In modern polishing machines, the retaining ring is pressed against the polishing pad. Due to the abrasive additives and chemistry in the slurry, the Chemical Mechanical Planarization (CMP) process causes wear on the retaining ring as it evens out irregular wafer topography, resulting in a flat wafer surface. Wear / lifetime Wear lifetime is the defined property...

Open the catalog to page 6

Purity To reduce the risk of metal contamination when manufacturing components for the semiconductor industry, any contact with metal material must be avoided, even from the plastic component. Ensinger high-performance plastics constantly meet or exceed these requirements and have therefore been tested by industry recognized laboratories on 16 common elements. Of these, the most important are: Mechanical data Excellent mechanical properties are important for efficient machinability of the retaining ring, less scrap during production of the ring and faster equipment set-up in the...

Open the catalog to page 7

Application examples Vacuum pick up tips TECASINT 1011 (PI) Low out-gassing. Low ion level. Thermally stable. Retaining ring TECATRON CMP (PPS) High wear resistance. Improved toughness and machinability. High dimensional stability. Support comb TECAPEEK GF30 (PEEK GF) High degree of toughness. High dimensional stability. Good chemical resistance. Electrically insulating. How does the new TECATRON CMP impact the cost of ownership (COO)? The CMP process is under constant development due to the drive to smaller process nodes. Consequently the main focus of CMP processes today is how to...

Open the catalog to page 8

Special materials for further semiconductor processes Products for semiconductor processes such as silicone wafer manufacturing, wafer cleaning and washing, CVD, photolithography, plasma etching, tools, chip handling, chip align and exposure : >>TECASINT 4111 (PI) >>TECASINT 4011 (PI) >>TECASINT 2011 (PI) >>TECAPEEK natural (PEEK) >>TECAPEEK GF30 (PEEK GF) >>TECATRON natural (PPS) >>TECATRON GF40 (PPS GF) >>TECAFLON PVDF (PVDF) >>TECAFLON PTFE (PTFE) >>TECADUR PET (PET) Function: For applications in the semiconductor industry, the following requirements are important: Benefits: Due to the...

Open the catalog to page 9

Special materials for back-end applications Products for back-end chip testing applications such as test socket carriers, contact frames, snap contacts and probe cards, burn-in test sockets, test adapters and spring contacts: >>TECASINT 5201 SD (PAI) >>TECASINT 5051 (PAI GF) >>TECASINT 4111 (PI) >>TECASINT 4011 (PI) >>TECATOR 5013 (PAI) >>TECAPEEK TS (PEEK) >>TECAPEEK CMF (PEEK) >>TECAPEEK ELS nano (PEEK) >>TECAPEEK natural (PEEK) >>TECATRON natural (PPS) >>TECAPEI GF30 (PEI GF) Function: Test sockets are used in back-end processes, after the circuits have been created on the wafers, for...

Open the catalog to page 10

Technical data for back-end applications The continuing reduction of component sizes in microchip production has placed increasing demands on materials of a new generation. Materials used for back-end applications have to show excellent properties in different areas: long term applications in wide temperature ranges, very good stiffness and strength and excellent dimensional stability with low reaction to thermal elongation or moisture absorption. Electrical properties TECASINT 5201 SD TECASINT 5051 TECASINT 4111 TECASINT 4011 TECATOR 5013 The specific surface resistance describes the...

Open the catalog to page 11All NYLATRON catalogs and technical brochures

-

Stock shapes

28 Pages

-

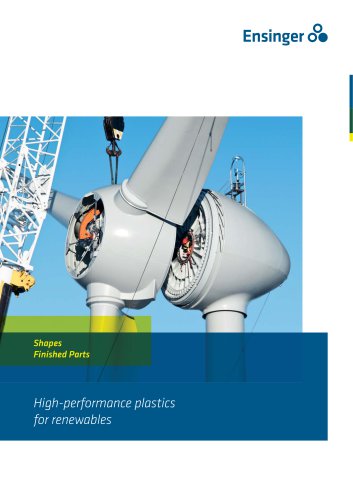

Shapes Finished Parts

8 Pages

-

TECATEC™

2 Pages