Website:

NYLATRON

Website:

NYLATRON

Catalog excerpts

Stock shapes Plastics used in food technology

Open the catalog to page 1

Content Food 4 Plastics in application: Food industry 7 Plastics in application: Beverage industry 8 Product portfolio 11 ID materials / UD materials 11 Materials with added value 12 Application examples 16 Quality assurance 17 Traceability 18 EU regulations 20 Migration tests 21 US regulations 22 Chinese regulations 23 Drinking water regulations 24 Chemical resistance 25 Frequently asked questions 2 6 Material standard values

Open the catalog to page 2

In many areas of industry, technical plastics play a vital role in improving the efficiency and competitive standing of customer applications. Lightweight, versatile plastics have a proven track record stretching back over many decades in the processing and packaging of foods. Their success is based on a combination of material benefits which are brought to bear even at raised temperature levels. These include primarily good mechanical properties and high resistance to chemicals. They are frequently used in this type of appli cation as gears, bearing bushes or in the form of other machine...

Open the catalog to page 3

Plastics in application: Food industry Dairy technology In the manufacture of cheese and dairy prod ucts, technical plastics are used in a number of different process steps, such as separating the whey and portioning, as well as transportation and cutting (for instance in SOS systems). Detergents put high demands on plastics in terms of chemical resistance. TECAPEEK TF10 blue fulfills these requirements and offers in addition high strength as well as excellent slide friction properties even at higher temperatu res. Furthermore it is optically detectable due to its blue color which leads to...

Open the catalog to page 4

Bakery technology Dough manufacture is one of the key process stages in the manufacture of baked goods. After mixing and stirring the ingredients, the dough is rolled out and shaped using, rolling machines and presses. Excess strain on components can result in pieces breaking off into the dough. This is the reason why many food producers use metal detectors. To avoid additional test procedures and added costs, Ensinger has developed a product range with inductively detectable plas tics. As the existing metal detectors are also suitable for tracing these new ID plastics, the safety of food...

Open the catalog to page 5

Food conveying Conveying systems are used to transport prod ucts from one machine to the next between the individual manufacturing steps. Where chain systems are used, the rollers must demonstrate good sliding properties and be highly resistant to wear. TECAMID 6 (PA 6) from Ensinger complies perfectly with these requirements. Conveying systems exist in which products are deep fried at 140 - 90 °C. Where this type of 1 temperature and grease resistance is called for, TECAPEEK (PEEK) is the material of choice. Food packaging At the end of the production chain, products are automatically...

Open the catalog to page 6

Plastics in application: Beverage industry Along with mineral water, a whole series of diff erent types of beverage are manufactured industrially and filled in vessels such as bot tles, cans or barrels. After consumption, the majority of empty bott les are returned for reuse. Ensinger is an im porant material supplier of machine compo t nents used in bottle sorting plants. Technical plastics such as TECAFORM AH (POM-C) are available in a range of colours and are ideally suited for use as bottle holders and grippers. After sorting, the bottles are cleaned inside and out. Cleaning plants...

Open the catalog to page 7

Product portfolio The basis for wide-ranging applications For food technology our product portfolio offers a wide range of engineering and high-performance plastics for various applications with our without food contact. Applications without direct food contact For components which do not come into contact with food, we offer a broad spectrum of engineer ing and high-performance plastics from our product range: Available product families: ˌˌTECAFORM (POM) ˌˌTECAMID (PA) ˌˌTECAST (PA 6 C) ˌˌTECAPET (PET) ˌˌTECANAT (PC) ˌˌTECAFLON (PVDF, PTFE) ˌˌTECASON (PPSU, PSU, PES) ˌˌTECATRON (PPS)...

Open the catalog to page 8

Applications with direct food contact Especially for components which come into direct contact with food, we offer a broad spectrum of suitable materials and issue the food conformity for their stock dimensions. This conformity complies to regulations (EC) No 1935/2004, (EU) No 10/2011 with migration results tested on semi-finished products and (EC) No 2023/2006 including FDA conformity on raw materials. We issue an order-related certificate of conformity for all in-stock dimensions of the following materials: Available materials of the standard portfolio: ˌˌTECAFORM AH natural (POM-C)*...

Open the catalog to page 9

Special portfolio for food technology: Besides our available standard stock portfolio we offer a special portfolio of materials fulfi iling the specific demands of food technology in terms of safety and performance. These materials comply of course just as well to the latest EU regulations and FDA conformi ty on raw materials. The most important ones of the following materials are available ex stock: Function: These plastics come complete with an additive to permit detection with the aid of a metal detector. Benefits: Broken fragments can be quickly traced as part of the standardized...

Open the catalog to page 10

ID materials The principle of detecting plastics in food stuffs is currently based on visual inspection (blue coloration). However, it is only possible to detect foreign bodies in food if the fragment is positioned close to the surface. In any other event, optical detection is not possible. In this case, any possible defect in a component is only noticed when it is far too late to prevent the destruction of large quantities of food if contamination has taken place. TECAMID 6 ID blue Very tough and impact resistant, high strength. Inductively detectable, conforming to food regulations....

Open the catalog to page 11

Application examples Deflector * TECAFORM AD natural (POM-H) High mechanical strength. Easily machined. Scraper TECAFORM AH ID grey (POM-C, detectable filler) Inductively detectable. Good toughness and strength. Good resistance to cleaning agents.

Open the catalog to page 12All NYLATRON catalogs and technical brochures

-

Stock shapes

15 Pages

-

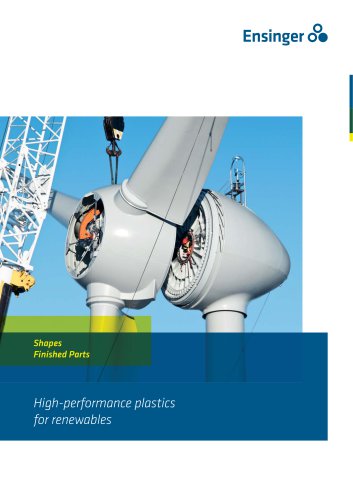

Shapes Finished Parts

8 Pages

-

TECATEC™

2 Pages