Website:

NT Tool

Website:

NT Tool

Catalog excerpts

Application Large Range of Shanks Feature No Rust Secure Gripping Reduction of Setup Time Reduction of Tool Cost —Easy collet change. œ Inexpensive straight shank drills can replace morse taper drills for tool cost reduction. œ Special purpose machines œ Transfer machines œ Machining centers œ NC lathes œ Automatic lathes œ Drilling machines, etc. œ Model DC in many trapezoidal shanks are available for 2.8 - 22.0mm diameter shanks. œ Model ED-A in many straight shanks are available for 2.8 - 16.0mm diameter shanks. œ In addition, small 0.5 - 7.0mm capacity chucks are available in Tr., straight and morse taper shanks. —Special Surface Treatment œ No rust under normal use conditions. No deterioration of precision due to rust. Minimum maintenance required. œ Drill shanks are securely and evenly gripped by EDC collets. œ Simply loosen the nut, and the drill can be easily removed from the drill chuck. The straight drill chucks can be turned into a quick change tooling system by combination use with drilling chuck and SSMA nut.

Open the catalog to page 1All NT Tool catalogs and technical brochures

-

Power Hydro Chuck

13 Pages

-

Collet Type Floating Holder

2 Pages

-

BCL - BT Clamper

1 Pages

-

UTS series

36 Pages

-

HSK-T series

8 Pages

-

HSK serires

85 Pages

-

AHO series

42 Pages

-

CAT series

55 Pages

-

BT series

142 Pages

-

HSK Clamper

1 Pages

-

Slim Hydro Chuck PHC·S

8 Pages

-

General Catalog

586 Pages

-

OTP Optical Tool Presetter

6 Pages

-

"R"- ZERO HOLDER

9 Pages

-

ZERO MASTER / ZM-1

1 Pages

-

MORSE TAPER ADAPTERS / MTA

2 Pages

-

TAP HOLDERS / TP3B

2 Pages

-

EASY PRESET SERIES / STM

11 Pages

-

SHRINKFIT HOLDERS / SRE

8 Pages

-

ER COLLET CHUCKS / ERC

12 Pages

-

HDC COLLET CHUCKS / HDC-A

7 Pages

-

GDC COLLET CHUCKS / GDC

4 Pages

-

R-ZERO SETTER / SPZ-2

1 Pages

-

EASY PRESET SERIES / SDM

7 Pages

-

HSK Tightening Fixture

2 Pages

-

Simple Setter

7 Pages

-

Side Lock Holders

8 Pages

-

Jacobs Taper Arbors

2 Pages

-

High Precision Coolant Collets

10 Pages

-

Chamfering Cutter Series

4 Pages

-

Quick Change Stub Tapper

4 Pages

-

Quick Change Stub Holder

5 Pages

-

Milling Chuck Collets

13 Pages

-

Contactless Tool Presetter

6 Pages

-

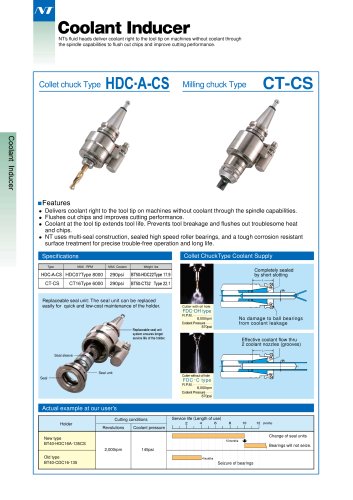

Coolant Inducer

4 Pages

-

Hyper Spindle

3 Pages

-

Angle Heads

7 Pages

-

Keyless Drill Chucks

2 Pages

-

Synchronous Tap Holder

11 Pages

-

Shrink-Fit Holders

8 Pages

-

Heating Device

3 Pages

-

R-Zero collet chucks

9 Pages

-

New Generation Milling Chucks

15 Pages