Website:

NT Tool

Website:

NT Tool

Catalog excerpts

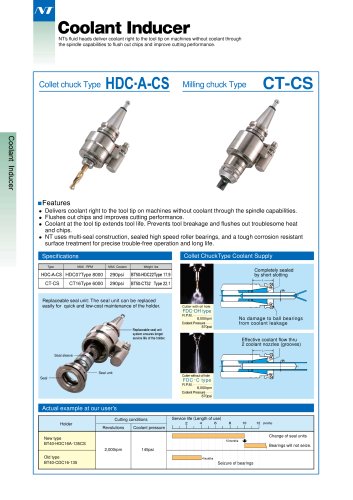

Collets for Semi-dry machining FDC-MS type

Open the catalog to page 1

Functions of coolant What is MQL (semi-dry) machining? Background of minimal coolant Background of minimal coolant ① Energy saving 5. Background of minimal coolant ② Disposal of waste coolant Semi-dry collets (MS collet) Function of MS collet Ms collet together with R-Zero holder MQL machining examples

Open the catalog to page 2

Three principal effects of coolant Lubrication : Lubrication of contact surface between cutting edge and workpiece. Suppressing the wear of cutting tools. Cooling : Removal of machining heat. Stable dimension precision. Prolonged tool life. Removal of chip : Removing chip during working, and preventing bite of chip. Transport and removal of chip around a work. Dry cutting with no use of coolant is the most ideal in terms of both Dry cutting with no use of coolant is the most ideal in terms of both environment and cost. environment and cost. However, it is very difficult to establish...

Open the catalog to page 3

2. M.Q.L machining method (Semi-dry machining) Minimum Quantity Lubrication Minimum Quantity Lubrication Machiningmethod with minimum amount of oiling. Machining method with minimum amount of oiling. M.Q.L machining in general refers to the method of supplying cutting oil about 33M.Q.L machining in general refers to the method of supplying cutting oil about 25ml/h and turning it into mist together with compressed air for feeding to cutting 25ml/h and turning it into mist together with compressed air for feeding to cutting point, which is also called semi-dry machining. point, which is also...

Open the catalog to page 4

3. Background for elimenating coolant ● Environmental problem Problem of coolant waste. Generation of hazardous substance Coolant contains hazardous materials such as chloric compound. Increase of industrial waste To be disposed as polluted sludge. ● Manufacturing cost Coolant treatment cost (Disposal of coolant + waste fluid) Energy consumption Cost associated with coolant. There is a report saying that is occupies 717% of working cost. Tool cost is 24% It is possible that treatment cost is raised by environmental problem. Electricity consumption of high-pressure or low-pressure coolant...

Open the catalog to page 5

4. Background for elimenating coolant. ① Energy saving Refilling coolant volume at company A. [ Auto parts production lines. ] 30,000 25,000 Energy consumption Transportation 搬送機 7% 7% 洗浄機 Cleaner 9% 9% Waste fluid 現在使用量 Current volume in use In conventional coolant system, a large amount of oil is used. 75% of the coolant will vaporize in the air. Approximately 30% of the electricity is consumed for coolant pumps in machining lines

Open the catalog to page 6

5. Background for elimenating coolant. ② Cost reduction of waste liquid disposal. 廃油 Waste oil 3% 3% 廃塗料 Waste point 8% 8% クーラント廃液 Waste coolant 42% Wastes generated from machining lines are slag, sludge, worn tools and waste fluid. 紙、木類 wood 30% Slag, sludge and worn tools can be recycled, while waste fluid must be burned. Disposal of waste liquid makes up 40% of total waste disposal cost.

Open the catalog to page 7

6. Collets for semi-dry machning FDC - MS type Short slits Oil mist discharging port in 6 positions.

Open the catalog to page 8

7. Function of collets for Semi-dry machining For tool without oil hole Injecting oil mist along the outer diameter of tool. (6 positions) For tool with oil hole Jet-spraying of oil mist to cutting edge and cutter's lateral face Lubrication for the cutting edge. Feed removal of chip. Lubrication for peripheral cutting edge. ・Preventing bite of chip. ・ Lubricating cutting edge from cutter's lateral face Lubrication for peripheral cutting edge. Injecting oil mist along the outer diameter of tool. (6 positions) ・ Optimum and calculated groove shape for injecting oil mist allows positive supply...

Open the catalog to page 9

《Patented 》 Effects of jet-spraying nozzle Jet- spraying from the nozzles Spraying nozzle By spraying relatively large particles alongside of a cutter, coolant will stick to workpiece surface and tool Dry fog whose particle size is less than 4 micrometers or less will not stick to the surface. Lubrication for flank friction. No leakage from slits. Coarsened particles By reducing the cross section of mist channel, the density of mist will increase, which results in larger particle size. Spraying nozzle The smaller the size of mist is, the more efficiently mist can be delivered with air. As...

Open the catalog to page 10

8. MS collet together with R-Zero holder R-Zero collet chuck + coolant collet for semi-dry machining = High precision deep hole making Run-out accuracy of the cutting edge is decreased to 2μm or less. R-zero collet holder Collet for Semi-dry machining

Open the catalog to page 11

9. Semi-dry machining example Φ5 Long drill with oil hole Deep hole machining (L/D = 20) Cutting conditions Holder Work piece Cutting tool BT30-HDZ09-75 + FDC-05009-MS MITSUBISHI MATERIAL Carbide drill with oil hole φ Tool length 130mm Semi-dry (Center through) Cutting speed Feed Cycle time 12 sec/ 1 hole (Excluding working time of guide hole.)

Open the catalog to page 12All NT Tool catalogs and technical brochures

-

Power Hydro Chuck

13 Pages

-

Collet Type Floating Holder

2 Pages

-

BCL - BT Clamper

1 Pages

-

UTS series

36 Pages

-

HSK-T series

8 Pages

-

HSK serires

85 Pages

-

AHO series

42 Pages

-

CAT series

55 Pages

-

BT series

142 Pages

-

HSK Clamper

1 Pages

-

Slim Hydro Chuck PHC·S

8 Pages

-

General Catalog

586 Pages

-

OTP Optical Tool Presetter

6 Pages

-

"R"- ZERO HOLDER

9 Pages

-

ZERO MASTER / ZM-1

1 Pages

-

MORSE TAPER ADAPTERS / MTA

2 Pages

-

TAP HOLDERS / TP3B

2 Pages

-

EASY PRESET SERIES / STM

11 Pages

-

SHRINKFIT HOLDERS / SRE

8 Pages

-

ER COLLET CHUCKS / ERC

12 Pages

-

HDC COLLET CHUCKS / HDC-A

7 Pages

-

GDC COLLET CHUCKS / GDC

4 Pages

-

R-ZERO SETTER / SPZ-2

1 Pages

-

EASY PRESET SERIES / SDM

7 Pages

-

Straight Drill Chuck

7 Pages

-

HSK Tightening Fixture

2 Pages

-

Simple Setter

7 Pages

-

Side Lock Holders

8 Pages

-

Jacobs Taper Arbors

2 Pages

-

High Precision Coolant Collets

10 Pages

-

Chamfering Cutter Series

4 Pages

-

Quick Change Stub Tapper

4 Pages

-

Quick Change Stub Holder

5 Pages

-

Milling Chuck Collets

13 Pages

-

Contactless Tool Presetter

6 Pages

-

Coolant Inducer

4 Pages

-

Hyper Spindle

3 Pages

-

Angle Heads

7 Pages

-

Keyless Drill Chucks

2 Pages

-

Synchronous Tap Holder

11 Pages

-

Shrink-Fit Holders

8 Pages

-

Heating Device

3 Pages

-

R-Zero collet chucks

9 Pages

-

New Generation Milling Chucks

15 Pages