Website:

NSM MAGNETTECHNIK GmbH

Website:

NSM MAGNETTECHNIK GmbH

Catalog excerpts

PRESS AUTOMATION SYSTEMS PRESS LINE AUTOMATION HIGH SPEED LINEAR FEEDER STACKING SYSTEMS DE-STACKING SYSTEMS HOT STAMPING AUTOMATION END-OF-LINE SYSTEMS

Open the catalog to page 1

PRESS LINE AUTOMATION Different types of presses can be adapted to our modular systems and give you the best return on your investment. Our standards products and pretested modular solutions reduce project risk, time and costs, ensuring an easy installation and maintenance. We also take care of upgrading existing press lines. Our experts are able to support customers in achieving and maintaining productivity of their capital assets. NSM Press to Press Automation Systems are in continuous evolution to become faster, with specific emphasis on reducing critical press occupation times. Full...

Open the catalog to page 2

HIGH SPEED LINEAR FEEDER HIGH SPEED LINEAR FEEDER (HSF) PRESS TO PRESS AUTOMATION • Reliable and approved linear kinematics • Fastest Feed stroke on the market • Easy to teach-in because of simple linear X and Z kinematics • Full 3D Line Simulation with Siemens Press Line Simulation PLS • Synchronization from Press to Press „On The Fly“ • Part Orientation Functions: Shifting, Rotating, Tilting • Payload 100 kg at max. acceleration/ deceleration HIGH SPEED FEEDER HOTFORMING AUTOMATION (HFF) • Maximum production capacity by optimal cycle times • Reliable and approved linear kinematics •...

Open the catalog to page 3

STACKING SYSTEMS NSM is the market and technology leading manufacturer of different stacking systems for magnetic, non-magnetic and aluminum blanks. Our own developments to stack precisely all kind of automotive blanks are the answer to the latest industry demands – such as patented hybrid conveyor system for steel an aluminum banks and pusher stacking systems for tailored blanks. TYPICAL OUTPUT DATA FOR STEEL AND ALUMINIUM BLANKS STACKING SYSTEM PERFORMANCE Start-Stop 100 SPM Continues-Run 120 SPM Pusher Matrix 90 SP

Open the catalog to page 4

DE-STACKING SYSTEMS Whether laid out for steel or aluminum blanks: highest flexibility, shortest fully automatically change-over times, great availability as well as long durability – these are the excellent features of NSM destacking system. The NSM modular design allows to custom-assemble the optimal destacker according to the press type. Dependent to the customer-specific requirements and output rate the destacker can either be carried out by robots, feeder or overhead conveyors. TYPICAL DESTACKER PERFORMANCE DATA FOR STEEL AND ALUMINUM BLANKS DESTACKER TYPE PERFORMANCE Transfer Press...

Open the catalog to page 5

HOT STAMPING AUTOMATION Hotforming enables the production of car body parts meeting highest safety and quality standards and reducing the component‘s weight at the same time. The method requires an automation process reproducible at any time. NSM realizes the whole automation chain; from the blank destacking system to the roller furnace via the pressing automation down to the fully automatic destacking of finished parts in transport racks or bins. CUSTOMER BENEFIT AT A GLANCE • Maximum production capacity by optimal cycle times • Scalable line layout in accordance with customer requireme

Open the catalog to page 6

END OF LINE SYSTEMS In order to guarantee a high degree of production reliability, flexibility, speed and maximum component quality in the handling of finished chassis parts, NSM offers manual and robot stacking systems for such parts, which meet the high requirements of modern component manufacturing. CUSTOMER BENEFIT AT A GLANCE • Stacking of single, double and quadruple parts • Stacking performance: 18 SPM • Integration of automatic quality control syst

Open the catalog to page 7

PRESS AUTOMATION SOLUTIONS For 50 years, the NSM Magnettechnik GmbH has ranked among the internationally leading manufacturers of handling systems for metals. We meet our customers‘ increasing requirements on quality and productivity with simultaneous flexibility and process reliability by comprehensive expertise in automation technology, mechanical engineering as well as control technology. Our most important customers are the automotive industry. Our design is based on our customers special requirements. This means: Freely scalable degree of automation and individual adaptation of the...

Open the catalog to page 8All NSM MAGNETTECHNIK GmbH catalogs and technical brochures

-

Types of conveyor belts

7 Pages

-

Datasheet GF398

8 Pages

-

Datasheet GF397

8 Pages

-

Datasheet GF380

9 Pages

-

Datasheet GF360

9 Pages

-

Datasheet

6 Pages

-

Datasheet

5 Pages

-

Datasheet

2 Pages

-

Datasheet

2 Pages

-

Datasheet

2 Pages

-

Datasheet

2 Pages

-

Datasheet

1 Pages

-

Datasheet

1 Pages

-

Datasheet

2 Pages

-

Datasheet

2 Pages

-

Datasheet

2 Pages

-

Datasheet

2 Pages

-

Datasheet

2 Pages

-

Datasheet

2 Pages

-

Datasheet

1 Pages

-

Datasheet

1 Pages

-

Datasheet

1 Pages

-

Belt Conveyor 360

9 Pages

-

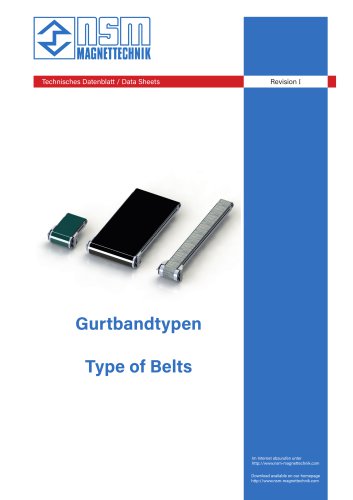

Type of Belts

7 Pages