Website:

NSK Europe Ltd.

Website:

NSK Europe Ltd.

Group: NSK Group

Catalog excerpts

MOTION & CONTROL NSK PRECISIONBEARINGS

Open the catalog to page 1

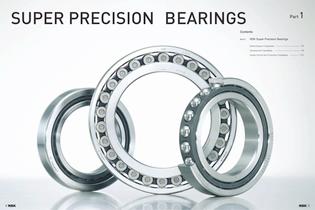

SUPER PRECISION BEARINGS Contents Part1. NSK Super Precision Bearings Global Support Capabilities –––––––––––––––––––––––– P6 Development Capabilities ––––––––––––––––––––––––– P8 Quality Control and Production Capabilities ––––––––– P10 4 5 Part1

Open the catalog to page 2

6 7 Part1 Part 2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 NSK is committed to manufacturing and selling products with consistently high quality anywhere in the world under the leadership of Technology Centers in the four major global markets. NSK’s sales offices, with expert staff that constantly explore customer needs, promote global network management that encompasses Technology Centers as well as production sites. NSK can respond quickly and effectively to the various needs of customers and supports their business development efforts in any region. Global Support Capabilities Uniform...

Open the catalog to page 3

8 9 Part1 Part 2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 NSK’s key technology is Tribology, the science of friction and wear. Tribology is a technology that focuses on saving energy and conserving resources by reducing friction and wear as well as preventing machine failure and thereby increasing reliability. NSK promotes the development of new products with a focus on four core technologies derived from Tribology. NSK’s key technology Development Capabilities Lubrication Technology Material Technology Through the relentless application of Tribology, NSK’s key technology, NSK has pursued...

Open the catalog to page 4

ISO 14001 Certification 10 11 Part1 Part 2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 As members of an ISO 9001-certified enterprise, all NSK plants adhere to strict international standards for quality control. NSK is also making an all-out, companywide effort to address environmental concerns as a top priority. Complete quality control and environmental responsibility NSK’s golden box guarantees the highest level of accuracy. NSK symbol ISO 9001 Certification NSK precision bearings deliver the highest level of accuracy, supported by our production capability, state-of-the-art equipment and...

Open the catalog to page 5

12 13 High Performance in the Next Generation NSK continually challenges the status quo to explore new possibilities. As our design philosophy does not allow us to compromise quality in manufacturing, we are driven to develop total solution technologies. By using the latest material and analysis technologies we are able to design and manufacture exceptional, high performance precision bearings. NSK will always strive to achieve the quality and performance that will be required in next generation bearings. Contents Part2. Features of Precision Bearings Metallurgical Technologies to Extend...

Open the catalog to page 6

14 15 Part 1 Part2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Metallurgical Technologies to Extend Bearing Life Z Steel as a Standard Material for Super-Precision Bearings SHX Steel Endures Ultra Speed Rotation Environments 0 106 107 108 5 10 20 30 Z Steel Vacuum degassed steel for the bearings in a wide variety of industries. Cycle Life, L10 Oxygen Content in Steel, ppm 5 10 15 0 20 40 60 80 100 120 140 160 180 200 Number of Particles Oxide Particle Size, m SUJ2 EP 3 m 40C. >5 m 5C. >10 m 0C. [O] : (5.5)ppm 1 200 View EP Steel ì ì ì ì Life, h Cumulative failure probability, % 99 90 80 70 60...

Open the catalog to page 7

16 17 Part 1 Part2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 0 5 000 10 000 15 000 20 000 25 000 0 10 20 30 40 50 60 70 80 Outer ring temperature rise, °C Steel balls Ceramic balls Speed, min–1 0 0 100 200 300 400 500 1 2 3 4 5 6 7 8 Speed, min–1 ×103 Dynamic frictional loss, w Rolling friction between balls and raceways Gyroscopic Slip Spin Slip Others 0 0 100 200 300 400 500 1 2 3 4 5 6 7 8 ×103 Dynamic frictional loss, w Rolling friction between balls and raceways Gyroscopic Slip Spin Slip Others Speed, min–1 Calculated result of heat generation The Outer Ring Temperature Rise in High...

Open the catalog to page 8

18 19 Part 1 Part2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Cage for Angular Contact Ball Bearings The temperature rise of the bearing with a TYN cage is lower than that with a Phenolic cage at a rotational speed lower than 1.4 million dmn Cage Performance Test Result Outer ring temperature rise, °C ×104 dmn T cage TYN cage 0 0 50 100 150 200 0 10 20 30 40 50 60 70 5 000 10 000 15 000 20 000 25 000 Speed min–1 Bearing: 65BNR10H-DB Preload after mounted: Position preload 300N Lubrication: Grease Cage for Double-Row Cylindrical Roller Bearings Ultra High-Speed Angular Contact Ball Bearings...

Open the catalog to page 9

20 21 Part 1 Part2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Angular Contact Ball Bearings (Standard Series) Angular Contact Ball Bearings (ROBUST Series) Bearing Components NSK super-precision bearings with optimal materials and internal design · Rings SUJ2 · Rolling elements Ceramics SUJ2 · Cage Polyamide Phenolic · Rings SHX SUJ2 · Rolling elements Ceramics SUJ2 · Cage Polyamide Phenolic PEEK · Rings SUJ2 · Rolling elements SUJ2 · Cages PPS Brass · Rings SHX SUJ2 · Rolling elements Ceramics SHX SUJ2 N10 · Cage PEEK Brass Cylindrical Roller Bearings Angular Contact Thrust Ball Bearings...

Open the catalog to page 10

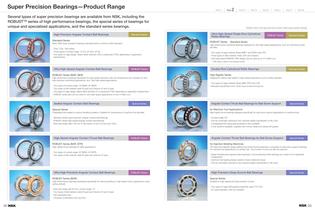

22 23 Part 1 Part2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Super Precision Bearings—Product Range Several types of super precision bearings are available from NSK, including the ROBUST™ series of high performance bearings, the special series of bearings for unique and specialized applications, and the standard series bearings. High Precision Angular Contact Ball Bearings Standard Series · 70xx, 72xx, 79xx series · Three types of contact angle: 15° (C), 25° (A5), 30° (A) · Two types of cage design: Select either phenolic (TR) or polyamide (TYN), depending on application requirements Basic...

Open the catalog to page 11All NSK Europe Ltd. catalogs and technical brochures

-

Ball Screws - BSS Series

1 Pages

-

Creep-Free Bearings Series

1 Pages

-

BNEQARTET Bearings

1 Pages

-

Agri Disc Hub

1 Pages

-

TF Series Bearings

1 Pages

-

Agri Disc Hub

1 Pages

-

HMS series

1 Pages

-

ROBOT MODULE™ MR SERIES

44 Pages

-

Precision Machine Components

55 Pages

-

Disc Harrow Bearings

2 Pages

-

ROLLING BEARINGS

707 Pages

-

TECHNICAL INSIGHT

2 Pages

-

Hub unit bearings

23 Pages

-

CONDITION MONITORING

6 Pages

-

BEARING MOUNTING TOOLS

28 Pages

-

Automotive Products

48 Pages

-

NSK IN EUROPE

6 Pages

-

Linear Guides Standard Items

62 Pages

-

Bearings for the Steel Industry

44 Pages

-

Bearing Replacement Guide

264 Pages

-

ROLLING BEARINGS

283 Pages

-

Bearings for the Cement Industry

20 Pages

-

Authorised Distributor

7 Pages

-

Added Value Training

12 Pages

-

Handling Instructions

48 Pages

-

Pocket Guide Linear Motion

44 Pages

-

Molded Oil™- Bearings

9 Pages

-

Plummer Blocks

52 Pages

-

Double Row Ball Bearing

44 Pages

-

Corporate Precision Components

24 Pages

-

Bearing Doctor

44 Pages

-

Self-Lube Hand book

160 Pages

-

Guide to RHP Self-Lube

12 Pages

-

Deep Groove Ball Bearings

12 Pages

-

Corporate Brochure

24 Pages

-

Bearings for Quarry and Mining

20 Pages

Archived catalogs

-

Troubleshooting poster

1 Pages

-

Ball Screw Support Bearings

44 Pages

-

Asset improvement programme

6 Pages

-

Bearings for Pumps & Compressors

24 Pages