Catalog excerpts

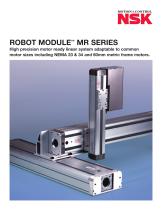

MOTION & CONTROL ROBOT MODULE™ MR SERIES High precision motor ready linear system adaptable to common motor sizes including NEMA 23 & 34 and 60mm metric frame motors.

Open the catalog to page 1

RH Module including extended stroke Pages 15 & 16 Support Slide Pages 35 & 36 Multi Axis Combinations Pages 21 to 34 Motor Mounting Kit Page 17 & 18

Open the catalog to page 2

Table of Contents General information, features, module construction, and CAD data downloads . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3 Product line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4 Application examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 5 & 6 Reference numbers, motor mounting positions and list of modules . . . . . . . . . . . . . . . . . . ....

Open the catalog to page 3

Robot Module™ - MR Series General Robot Modules are complete linear axis high precision systems for various automation applications in the semiconductor, electronic, and medical industries as well as the automated assembly and production areas. Built in our Franklin, Indiana manufacturing facility using high-quality NSK Linear Guides, NSK Ball Screws and NSK Monocarriers assures that a high level of mechanical reliability is achieved. NSK offers this sophisticated technology in an ergonomic design enclosed in an aluminum housing. The motorless design of these Robot Modules allows users the...

Open the catalog to page 4

Robot Module – MR Series Product Line Multi Axis Combinations (Pages 21 to 34) Motor Mounting Kit (Pages 17 & 18) Support Slide (Pages 35 & 36) Combining Brackets (Pages 37 to 39)

Open the catalog to page 5

Robot Module – MR Series Application Examples 1 – Transfer of syringes 2 – Palletization of electronic parts Conveyor Package Belt conveyor Conveyor Sensor Belt conveyor 3 – Loader/unloader for inspection device 4– Loader/unloader for inspection device L X Y Gripper Magnet roller CCD camera Sensor 6 – Work feed in stamping machine 5– Screw-tightening machine in assembly line Main unit Screw hopper stroke Screw-tightening head

Open the catalog to page 6

7– Automobile taillight bonding 8 – Deflashing device for core of sand mold Main unit stroke Adhesive dispenser Main unit stroke Round bar Flash Core of sand-mold for engine 9 – Polyethylene can processing machine 10– Parts loader/unloader for processing machinery Main unit stroke Cutting head

Open the catalog to page 7

Robot Module – MR Series Reference Numbers The reference number for the Robot Module is composed of the basic specifications of the unit. XY-HRS O -RS 1 38 X Y- H R S O1 - RS Robot Module The RS Module is delivered with right or left motor mounts preassembled. It is not available in a straight motor mount configuration or with no motor mount attached. The RS Modules are available with metric or NEMA 23 motor mounting hole patterns. Motor Interface A: Metric B: NEMA 23 N: No Motor Interface RH and RM Module ordering directions Both the modules and motor mounting kits are purchased...

Open the catalog to page 8

Straight Motor Right Motor Left Motor List of Modules Robot Module Notes: 1) If your payload exceeds listed value call NSK. 2) The individual moment capacities are defined as the value at which the fatigue life is 10,000 km when that moment acts continuously on the linear guide.

Open the catalog to page 9

RS Module - Left Motor Mount

Open the catalog to page 10

Robot Module™ - MR SeriesRS Module - Left Motor Mount Note: Reference number designates modules with motor mounting kit. Note: Maximum input torque is 1.9 N-m 1) If your payload exceeds listed value call NSK. 2) The individual moment capacities are defined as the value at which the fatigue life is 10,000 km when that moment acts continuously on the linear guide. Module mounting plates - page 40 • Limit sensor kits - page 41 • Square nut - page 42 V

Open the catalog to page 12

Robot Module™ - MR Series RS Module - Right Motor Mount Note: Reference number designates modules with motor mounting kit. Module mounting plates - page 40 • Limit sensor kits - page 41 • Square nut - page 42 Options Linear Guide Moment Capacities2 Note: Maximum input torque is 1.9 N-m 1) If your payload exceeds listed value call NSK. 2) The individual moment capacities are defined as the value at which the fatigue life is 10,000 km when that moment acts continuously on the linear guide.

Open the catalog to page 13

Robot Module Notes

Open the catalog to page 14

Motor Mounting Kit Reference Number Linear Guide Moment Capacities2 Note: Maximum input torque is 3.8 N-m 1) If your payload exceeds listed value call NSK. 2) The individual moment capacities are defined as the value at which the fatigue life is 10,000 km when that moment acts continuously on the linear guide. Motor Mounting Kits Motor mounting kits - pages 17 & 18 • Module mounting plates - page 40 • Limit sensor kits - page 41 • Square nut - page 42 NSK

Open the catalog to page 15

Robot Module™ - MR Series RH Module - Straight Motor Mount Motor Mounting Kit Reference Number Linear Guide Moment Capacities2 Note: Maximum input torque is 3.8 N-m 1) If your payload exceeds listed value call NSK. 2) The individual moment capacities are defined as the value at which the fatigue life is 10,000 km when that moment acts continuously on the linear guide. 15 NSK Motor mounting kits - pages 17 & 18 • Module mounting plates - page 40 • Limit sensor kits - page 41 • Square nut - page 42

Open the catalog to page 16

Reference Number Linear Guide Moment Capacities2 Rolling Moment [Nm] 1) If your payload exceeds listed value call NSK. 2) The individual moment capacities are defined as the value at which the fatigue life is 10,000 km when that moment acts continuously on the linear guide. Motor mounting kits - pages 17 & 18 • Module mounting plates - page 40 • Limit sensor kits - page 41 • Square nut - page 42 NSK

Open the catalog to page 17

Robot Module – MR Series Motor Mounting Kits Motor Mounting Kits provide the hardware necessary to connect NEMA 23, NEMA 34 or 60mm Frame Metric motors to the base module. These kits allow the user the flexibility to attach motors of their choice to the base module. See opposite page for definition of the various motor interfaces. There are two kits for the RS module, five kits for RH/RM 1000mm and six kits for the RH extended module > 1200mm. The motor mounting kit for the RS module comes installed and ready to accept the user's motor. Shaft Coupling PN XY-P5584RM, 60mm Frame Metric Motor...

Open the catalog to page 18All NSK Europe Ltd. catalogs and technical brochures

-

Ball Screws - BSS Series

1 Pages

-

Creep-Free Bearings Series

1 Pages

-

BNEQARTET Bearings

1 Pages

-

TF Series Bearings

1 Pages

-

HMS series

1 Pages

-

Precision Machine Components

55 Pages

-

Disc Harrow Bearings

2 Pages

-

ROLLING BEARINGS

707 Pages

-

TECHNICAL INSIGHT

2 Pages

-

Hub unit bearings

23 Pages

-

CONDITION MONITORING

6 Pages

-

BEARING MOUNTING TOOLS

28 Pages

-

Automotive Products

48 Pages

-

NSK IN EUROPE

6 Pages

-

Linear Guides Standard Items

62 Pages

-

Bearings for the Steel Industry

44 Pages

-

Bearing Replacement Guide

264 Pages

-

ROLLING BEARINGS

283 Pages

-

Bearings for the Cement Industry

20 Pages

-

Authorised Distributor

7 Pages

-

Added Value Training

12 Pages

-

Handling Instructions

48 Pages

-

Pocket Guide Linear Motion

44 Pages

-

Molded Oil™- Bearings

9 Pages

-

Plummer Blocks

52 Pages

-

Double Row Ball Bearing

44 Pages

-

Corporate Precision Components

24 Pages

-

Bearing Doctor

44 Pages

-

Self-Lube Hand book

160 Pages

-

Guide to RHP Self-Lube

12 Pages

-

Deep Groove Ball Bearings

12 Pages

-

Corporate Brochure

24 Pages

-

Bearings for Quarry and Mining

20 Pages

Archived catalogs

-

Agri Disc Hub

1 Pages

-

Troubleshooting poster

1 Pages

-

Super Precision Bearings

120 Pages

-

Ball Screw Support Bearings

44 Pages

-

Asset improvement programme

6 Pages

-

Bearings for Pumps & Compressors

24 Pages