Catalog excerpts

MOTION & CONTROL™ LINEAR GUIDES STANDARD ITEMS

Open the catalog to page 1

As one of the world's leading manufacturers of rolling bearings, linear technology components and steering systems, we can be found on almost every continent - with production facilities, sales offices and technology centres - because our customers appreciate short decision-making channels, prompt deliveries and local service. NSK commenced operations as the first Japanese manufacturer of rolling bearings back in 1916. Ever since, we have been continuously expanding and improving not only our product portfolio but also our range of services for various industrial sectors. In this context,...

Open the catalog to page 4

Partnership based on trust – and trust based on quality Total Quality by NSK: The synergies of our global network of NSK Technology Centres. Just one example of how we meet our requirements for high quality. NSK is one of the leading companies with a long tradition in patent applications for machine parts. In our worldwide research centres, we not only concentrate on the development of new technologies, but also on the continual improvement of quality based on the integrated technology platform of tribology, material technology, analysis and mechatronics. More about NSK at www.nskeurope.com...

Open the catalog to page 5

Linear Guides Types of Linear Guides LH/SH Series • General versatility for heavy-duty applications • Large load carrying capacity against vertical direction Stainless steel is available (#15-30). • Silent and smooth featured LH incorporated with retainer piece LS/SS Series • Compact designed NSK basic series • General versatility for fine application • Large load carrying capacity against vertical direction Stainless steel is available (#15-35). • Silent and smooth featured LS incorporated with retainer piece • A roller guide with super high load capacity and rigidity • Super high accuracy...

Open the catalog to page 6

Ball slide model Size & Preload Slight preload Slight preload Medium preload Slight preload Maximum clearance Maximum clearance Maximum clearance

Open the catalog to page 7

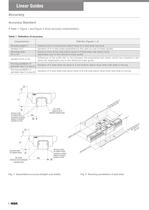

Linear Guides Accuracy Accuracy Standard Table 1 Definition of accuracy Characteristics Definition (Figures 1, 2) Mounting height H Variation of H Distance from A (rail bottom datum face) to C (ball slide top face) Variation of H in ball slides assembled to the rails of a set of linear guides Mounting width W2 or W3 Distance from B (rail side datum face) to D (ball slide side datum face). Applicable only to the reference linear guide. Variation of W2 or W3 Difference of the width (W 2 or W 3 ) between the assembled ball slides, which are installed in the same rail. Applicable only to the...

Open the catalog to page 8

Assembly dimension tolerance of random-matching type Unit: *1 Variation of mounting height H is specified on one rail. *2 Variation of mounting height H is specified on multiple rails. Running parallelism tolerance of random-matching type: A//C or B//D Unit: urn Available rail length (max. length)

Open the catalog to page 9

Linear Guides NSK PH-Series (Precision accuracy grade / Random matching)

Open the catalog to page 10

Running parallelism of PH grade is equivalent to P5 grade of NSK matched rail / ball slide assembly. Accuracy grade (running parallelism) can be specifi ed as PH or PC. Assembly accuracy of PH grade is shown below. Note: 1) Variation on the same rail 2) Variation on multiple rails The preload can be specified as H (medium) or Z (slight). Part number Part number for ball slide only Part number for rail only NSK control number Series Preload Z: Slight preload, H Medium preload Part number for assembly Preload Z: Slight preload (Common rail for sight or medium preload) Accuracy grade PH:...

Open the catalog to page 11

Linear Guides Double Seal and Protector • Double seal (a combination of two end seals) to enhance seal function. • Protector (a steel plate added on end seal) to prevent high temperature fine particles, such as welding spatter and other foreign matter, from entering the ball slide. *** Consult with NSKwhen attaching a connector to a drive-in type grease fitting • When a double seal or protector is installed, the ball slide becomes longer by the sizes shown in Tables 2 • When attaching a grease fitting to the end-cap after the double seal or protector is equipped, a connector, shown in Fig....

Open the catalog to page 12

Cap to Cover Bolt Hole for Rail Mounting • After the rail is mounted to the machine base, a cap is used to cover the bolt hole to prevent foreign matter from clogging up the hole or from entering the • The cap for the bolt hole is made of synthetic resin, which is superb in its resistance to oil and wear. • Table 4 shows sizes of the bolts for each model number as well as reference numbers of caps. • To insert a cap into the rail bolt hole, use a flat tool (Fig. 6). Pound the cap gradually until its top becomes flush with the rail top face.

Open the catalog to page 13

Linear Guides LH Series Ball Slide Models: AL, AN, BL, BN Front view of AL and AN, BL and BN types Side view of BN type Note 1: External appearance of stainless steel ball slides differs from those of carbon steel ball slides Part number for ball slide only Part number for rail only ball slide No code: Carbon steel temperature chrome temperature chrome Material/surface treatment Preload Z: Slight preload Preload H: Medium preload Butting rail specification Accuracy grade (*** is required when making

Open the catalog to page 14

Side view of AN type Note 2: Basic dynamic load rating C is a load that allows for a 50-km rating fatigue life and is a vertical and constant load on the ball slide mounting surface To convert C to C100 for a 100-km fatigue life, divide C by 1.26 Part number for assembly (ball slide + rail) Material/surface treatment C: Carbon steel (NSK standard) D: Carbon steel + surface treatment H: Stainless steel + surface treatment Preload Z: Slight preload Preload H: Medium preload Accuracy grade PC: Normal grade, KC: PC with NSK K1 PH: Precision grade, KH: PH with NSK K1 (*** is required when making...

Open the catalog to page 15

Linear Guides LH Series Side view of GM type Note 1: Parenthesized dimensions are for items made of stainless steel Note 2: External appearance of stainless steel ball slides differs from those of carbon steel ball slides Part number for ball slide only Part number for rail only ball slide No code: Carbon steel temperature chrome temperature chrome Preload Z: Slight preload Preload H: Medium preload Material/surface treatment Butting rail specification Accuracy grade (*** is required when making

Open the catalog to page 16All NSK Europe Ltd. catalogs and technical brochures

-

Ball Screws - BSS Series

1 Pages

-

Creep-Free Bearings Series

1 Pages

-

BNEQARTET Bearings

1 Pages

-

TF Series Bearings

1 Pages

-

HMS series

1 Pages

-

ROBOT MODULE™ MR SERIES

44 Pages

-

Precision Machine Components

55 Pages

-

Disc Harrow Bearings

2 Pages

-

ROLLING BEARINGS

707 Pages

-

TECHNICAL INSIGHT

2 Pages

-

Hub unit bearings

23 Pages

-

CONDITION MONITORING

6 Pages

-

BEARING MOUNTING TOOLS

28 Pages

-

Automotive Products

48 Pages

-

NSK IN EUROPE

6 Pages

-

Bearings for the Steel Industry

44 Pages

-

Bearing Replacement Guide

264 Pages

-

ROLLING BEARINGS

283 Pages

-

Bearings for the Cement Industry

20 Pages

-

Authorised Distributor

7 Pages

-

Added Value Training

12 Pages

-

Handling Instructions

48 Pages

-

Pocket Guide Linear Motion

44 Pages

-

Molded Oil™- Bearings

9 Pages

-

Plummer Blocks

52 Pages

-

Double Row Ball Bearing

44 Pages

-

Corporate Precision Components

24 Pages

-

Bearing Doctor

44 Pages

-

Self-Lube Hand book

160 Pages

-

Guide to RHP Self-Lube

12 Pages

-

Deep Groove Ball Bearings

12 Pages

-

Corporate Brochure

24 Pages

-

Bearings for Quarry and Mining

20 Pages

Archived catalogs

-

Agri Disc Hub

1 Pages

-

Troubleshooting poster

1 Pages

-

Super Precision Bearings

120 Pages

-

Ball Screw Support Bearings

44 Pages

-

Asset improvement programme

6 Pages

-

Bearings for Pumps & Compressors

24 Pages