Catalog excerpts

5F Shinminamioi Bldg., 1-13-5, Minamioi, Shinagawa-ku, Tokyo 140-0013 Japan &£±(DÌÈM Attention on Safety 1) ^#6KtjtìTieiis xmroirí titbit, sft*f*¥citfê»n* 3) XJUffifflT-SBli, «»r*ftl£](/* Uitroe #-f */<- • «BM 1 ) When removing tools from cases, be careful of getting-out of tools and don't touch directly the cutting edges. 2) Never touch the cutting edges directly with bare hand. 3) Use safety covers and eye protection, as tools may be broken. 4) Use holders, etc. that match the tools and nature of the processing operations. The tool should be firmly attached to the holder to prevent shaking. 5) The work materials clamp firmly. 6) Make sure of dimensions of tools and work pieces before starting operation. 7) It Is necessary to adjust conditions according to the dimensions of work materials and the machine. 8) Select a cutting fluid appropriate to the particular usage. Using a non-water cutting fluid could lead to fires due to sparks generated during processing or heat caused by breakage. Ensure that you take proper fire-prevention measures. 9) If abnormal sound, etc. occurs during processing, stop the machine immediately. 10) Dont modify tools. & Specifications may change without notice for improvement.

Open the catalog to page 1

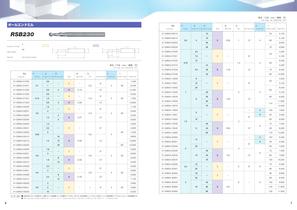

Helix Angle Micro Grain Carbide Unit (Size : mm / Retail Price : JPY) ■ When you order, Indicate RSB230 (R) x (£) x [x (£ 1)]. Choose shank dia (d) ; 3mm (4mm) or 6mm for 1.5R (2R)«(y°) is reference value. Unit (Size : mm / Retail Price : JPY)

Open the catalog to page 4All NS TOOL catalogs and technical brochures

-

ALZ345

3 Pages

-

PCDRB

2 Pages

-

MRBH230

4 Pages

-

MSBH345

3 Pages

-

DCMB

2 Pages

-

MMTM-Lineup Expansion!

2 Pages

-

PCDRB-PCD Ball End Mill

2 Pages

-

PCD Square End Mill

2 Pages

-

End Mill for Aluminum

5 Pages

-

CBN Micro-Edge ?Z?

3 Pages

-

CBN Super Surface End Mill

2 Pages

-

MICRO DRILL SERIES

3 Pages

-

Ball End Mill for Aluminum

3 Pages

-

Micro thread cutting tool

2 Pages