Catalog excerpts

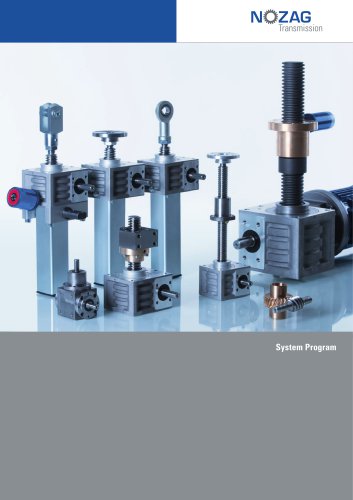

System Program

Open the catalog to page 1

What counts is success – We help you achieve it Today clear competitive advantages and opportunities depend on flexibility, speed, innovation and continuous improvement. We understand that time has become one of the most significant competitive factors. In clearly defined markets, we offer advanced solutions that aim at optimum customer value. With internationally recognized quality, – our entire company is certified according to ISO 9001:2008 – high stock availability and maximum reliability, we aim at being a true partner for our customers. We are aware that a lasting partnership is built...

Open the catalog to page 2

Product overview System Program 1 Screw jacks 2 Bevel gearboxes 3 Connecting shafts 4 Linear drives 5 Gear, worm gear 6 Customer-specific construction group Standard Program 1 Spur gears module 0.3 to 8 2 Bevel gears up to module 6 3 Worms and worm wheels 4 Standard racks 5 Trapezoid threaded screws, trapezoid threaded nuts 6 Chains and chain wheels 7 Couplings 8 Hardened precision steel shafts 9 Manufacturing according to drawing Request our separate catalog «Standard Program»

Open the catalog to page 3

Successful solutions It couldn’t be easier: www.nozag.ch ser-friendly catalog. If required, download individual catalog U pages for your documentation. ■ D-CAD download from the entire range of Nozag products If you wish to be advised or supported in any way, we will be pleased to do this by phone or on site. As a drive systems specialist, we deal with the development, manufacture and sale of standard or custom-designed gear components, sprockets, screw jacks, bevel gear drives, linear drives as well as other drive system components and special gears. Nozag’s products are manufactured...

Open the catalog to page 4

Assembly and Operating Manu Individual products and services Modular system / Layout procedure / Practical applications / Application requirements / Base values / Design/Calculation 2. Screw jacks, non-rotating Application examples / Checklist / Sizes/System overview / Sizes/Models / Attachments / Length determination / Section drawing 3. Screw jacks, rotating g. Application examples / Checklist / Sizes/System overview / Sizes/Models / Attachments / Length determination / Section drawing Connecting shafts / Pedestal bearings / Clamp coupling / Flexible couplings / Bevel gear LMA/ Bevel gear...

Open the catalog to page 5

Screw jacks from our own production facility To view the screw jack in all its facets as a standard machine element, that is a dream of many designers and machine builders. Defined force up to 1000 kN ■ ational design through complete modular sets – through-and-through R compatible ■ verything from a single source minimises the procurement effort E ■ upply of pre-assembled units and assemblies including motors S ■ hort delivery times S ■ onstant speed forward and back, corresponding to the rotational speed C of the drive motor ■ djustable stroke We have already accepted this challenge a few...

Open the catalog to page 6

Non-rotating spindle The worm wheel is provided with a female thread and converts the rotational movement into an axial movement of the spindle, when the latter is prevented from rotating (through its design or by means of an anti-rotation protection in the protection tube). Rotating spindle The spindle has a fixed connection to the worm wheel and rotates with it. The nut therefore screws itself up and down.

Open the catalog to page 7

1.2 Modular system General/Basics The modular, flexible and innovative screw jack kit in a wide performance range from 2 to 1000kN makes perfect drive solutions from low-cost standard components. Through the new gearbox series N, the kit not only includes the use of high-quality materials, innovative coatings and high-performance components, but is also subject to the highest standards of functionality, quality and design. Your construction will be simpler and cost effective > Easy assembly with standardized individual components from the kit. You save time > less specific designs, because...

Open the catalog to page 8

1.3 Layout procedure General/Basics Feasibility study 1. Quotation 2. Technical drawing 3. Purchase order 1. Delivery 2. Assembly and installation 3. Commissioning Design 1. Tensile or compressive load 2. Buckling 3. Lifting speed 4. Critical bending speeds 5. Duty cycle Do come to us with your concerns and wishes. We would be happy to discuss this situation with you and consider the problem. After the analysis, we will define the objectives that have to be reached in terms of content, scope and time. Ambient conditions 1. Chemicals, aggressive media 3. Corrosion 4. Temperatures, humidity...

Open the catalog to page 9

1.4 Practical applications General/Basics Practical applications 1 Packaging Correct height setting for filling 2 Research Exact positioning of the measuring instrument for sunlight 3 Sunshade Opening and closing the sunshade 4 Silo cover Controlled closing and opening of the cover 5 Textile industry Reliable positioning despite vibrations 6 Solar tracker Fine-positioning of solar panels 7 Space Travel Exact levelling, due to individually controllable lifting jacks 8 Lifting carriage Manual positioning of pipes 9 Garage lift Space-saving solution through lifting one of the vehicles 10...

Open the catalog to page 10

1.4 Practical applications General/Basics

Open the catalog to page 11

1.5 Application requirements General/Basics Selection of Screw Jack System and Arrangement Application requirements S-Version standing spindle R-Version rotating spindle Parameter see checklist (page 29–30) Parameter see checklist (page 65–66) Pre-selection of screw jack size System overview (page 31) Pre-selection of screw jack size System overview (page 67) Tension load Compression load Compression load Tension load Buckling calculation (page 17–18) Buckling calculation (page 17–18) Critical speed (page 19–20) min. spindle diameter (possibly select a bigger screw jack type and check...

Open the catalog to page 12

1.5 Application requirements General/Basics Construction and layout The selection or the dimensioning is determined by the customer, since we are not familiar with the construction conditions like the place of application and the type of operation. If desired, we can be of help for the selection and design of the layout, and can generate assembly drawings and calculations for you on the basis of your rating parameters, as suggestions. The gearboxes are conceived in accordance with the load and duty cycle shown in the catalogue, for industrial purposes. We request you to check with us for...

Open the catalog to page 13