Website:

norelem - Éléments standard mécaniques

Website:

norelem - Éléments standard mécaniques

Group: norelem

Catalog excerpts

Couplings Rigid couplings Keyless locking couplings Cardan joints Quick-fit couplings Bearings Seals

Open the catalog to page 1

Technical information for couplings Note: The zero backlash, flexible metal bellows or elastomer couplings are particularly suited to highly accurate drives with average torque values. They are the ideal solution for accurately connecting two shaft journals at a true angle. Axial, radial and angular displacement between two ends of a shaft can be compensated within defined limits. This produces minimal bearing stresses as a result of the low restoring forces. A strong shaft to hub connection guarantees zero backlash transmission of torque, even without additional parallel key. Low mass...

Open the catalog to page 2

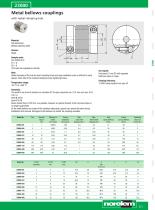

23000 Metal bellows couplings Version: Bright. Sample order: nlm 23000-012, D1 = 6 D2 = 6 (The hubs are supplied pre-bored). On request: Hub bores D1 and D2 with separate tolerance class or range. Note: Radial clamping of the hub for short mounting times and easy installation even in difficult to reach spaces. Take note of the required clamping screw tightening torque. Drawing reference: 1) EASY clamp system from size 20 Assembly: The shaft to hub bore fit should be a transition fit. The play should be min. 0.01 mm and max. 0.04 mm. i.e: shaft Ø 28 k6 bore Ø 28 F6. Bores smaller than D1/D2...

Open the catalog to page 3

23002 Metal bellows couplings clamping with grub screw L2 Material: Hub aluminium. Bellows stainless steel. Version: Bright. Sample order: nlm 23002-0004, D1 = 3 D2 = 3 (The hubs are supplied pre-bored). Note: Clamping the hub with a grub screw is a cost-effective alternative to the metal bellows couplings with radial clamping hub (23000). Short mounting times and an easy installation even in difficult to reach places. Take note of the required tightening torque for the grub screw. To ease removal, a flat milled on the shaft is recommended. Temperature range: -20 °C to +90 °C. Assembly: The...

Open the catalog to page 4

23010 Beam couplings with radial clamping hub, aluminium L1 Material: Aluminium. Version: Bright. Sample order: nlm 23010-1016, D1 = 2.5 D2 = 2.5 (The hubs are supplied pre-bored). Attention: Procedure for enlarging pre-drilled bores D1/D2: Note: Zero backlash, torsionally rigid, resiliently flexible and maintenance-free full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Temperature range: -50 °C to +150 °C. Drill the bore out using...

Open the catalog to page 5

23010 Beam couplings with radial clamping hub, stainless steel L1 Material: Stainless steel 1.4305. Version: Bright. Sample order: nlm 23010-2016, D1 = 2.5 D2 = 2.5 (The hubs are supplied pre-bored). Attention: Procedure for enlarging pre-drilled bores D1/D2: Note: Zero backlash, torsionally rigid, resiliently flexible and maintenance-free full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Drill the bore out using a small as...

Open the catalog to page 6

23012 Beam couplings with removable clamping hub, aluminium L1 Material: Aluminium. Version: Bright. Note for ordering: D1 and D2 are customer specific e.g. 23012-1025; D1 = 5H7, D2 = 8H7 Note: Zero backlash, torsionally rigid, resiliently flexible and maintenance-free full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Assembly: Recommended shaft tolerances h7. Moment of inertia (10⁻³ kgm²) Max. axial shaft displacement ± Max....

Open the catalog to page 7

23012 Beam couplings with removable clamping hub, stainless steel L1 Material: Stainless steel 1.4305. Version: Bright. Note for ordering: D1 and D2 are customer specific e.g. 23012-2025; D1 = 5H7, D2 = 8H7 Note: Zero backlash, torsionally rigid, resiliently flexible and maintenance-free full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Temperature range: -50 °C to +150 °C. Assembly: Recommended shaft tolerances h7. Moment of...

Open the catalog to page 8

23021 Elastomer dog couplings with conical hub and clamping ring (similar to DIN 69002) L On request: Hub bores D1 and D2 with separate tolerance class or range. Drawing reference: 1) elastomer spider Moment of inertia (10⁻³ kgm²) Static resistance to torsion Nm/arcmin Max. axial shaft displacement ± Max. lateral shaft displacement Radial spring stiffness N/mm Tightening torque of screws Nm Assembly: The shaft to hub bore fit should be a transition fit. The play should be max. 0.02 mm. i.e: shaft Ø 25 k6 bore Ø 25 G6. Bores smaller than D1/D2 min. are possible, however an optimal transfer...

Open the catalog to page 9

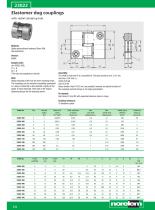

23022 Elastomer dog couplings with radial clamping hub Material: Spider polyurethane hardness Shore 98A. Hub aluminium. Version: Bright. Sample order: nlm 23022-008, D1 = 6 D2 = 6 (The hubs are supplied pre-bored). Assembly: The shaft to hub bore fit is a transition fit. The play should be min. 0.01 mm and max. 0.04 mm i.e. shaft: Ø 28 k6 hub: Ø 28 F6 Bores smaller than D1/D2 min. are possible, however an optimal transfer of the couplings nominal torque is no longer guaranteed. Note: Radial clamping of the hub for short mounting times. The couplings can be mounted completely assembled or a...

Open the catalog to page 10

clamping with grub screw Material: Spider polyurethane hardness Shore 98A. Hub aluminium. Version: Bright. Sample order: nlm 23023-0020, D1 = 3 D2 = 3 (The hubs are supplied pre-bored). Note: Clamping the hub with a grub screw is a cost-effective alternative to the elastomer dog couplings with radial clamping hub (23022). Short mounting times. The couplings can be mounted completely assembled or plug-in mounting is also possible. Lightly oil the spider to ease assembly. Take note of the required tightening torque for the grub screw. To ease removal we recommend milling a flat on the shaft....

Open the catalog to page 11All Norelem - Éléments standard mécaniques catalogs and technical brochures

-

Assembly system

72 Pages

-

Pneumatic cylinder

9 Pages

-

Drive technology

235 Pages

-

Tube connectors - Tube columns

59 Pages

-

Concentricity elements

10 Pages

-

Connectors Energy chains

18 Pages

-

Power supply units

3 Pages

-

Sensor technology

4 Pages

-

Motors - Lifting columns

11 Pages

-

Material handling and transport

45 Pages

-

technoshop

38 Pages

-

BROCHURE TELESCOPIC SLIDES 2021

88 Pages

-

PRODUCT OVERVIEW EDITION 2022

43 Pages

-

THE BIG GREEN BOOK edition 2022 vol.2

1336 Pages

-

THE BIG GREEN BOOK edition 2022 vol.1

1380 Pages

-

Guide rails norelem

20 Pages

-

ALUMINIUM PROFILES

104 Pages

Archived catalogs

-

01250

2 Pages

-

01148 Subplates

1 Pages

-

Norelem Edition 2019

1986 Pages

-

THE BIG GREEN BOOK edition 2019

1986 Pages

-

THE BIG GREEN BOOK 2018

1767 Pages

-

BIG GREEN BOOK 2017

1590 Pages

-

BGB

1456 Pages

-

BIG GREEN BOOK

1 Pages

-

01148 Pallets

1 Pages

-

01127 Base plates

1 Pages

-

01060 Steel base plates

1 Pages