Website:

norelem - Éléments standard mécaniques

Website:

norelem - Éléments standard mécaniques

Group: norelem

Catalog excerpts

Motors Lifting columns

Open the catalog to page 1

Version: 2-phase high-torque stepper motor in NEMA 17, NEMA 23 and NEMA 34 sizes with flat-milled shaft (D-shaft). 1.8° increment angle (full increment) with 4-wired connection cable. Sample order: nlm 85000-230180 Note: The stepper motors deliver high torque, high precision and simple control. They function reliably in diverse ambient conditions. The stepper motors can be connected to conventional motor controllers via stranded cables. When selecting a suitable motor, using just the retaining torque is not enough, as the motor’s torque decreases with the speed. It is therefore essential to...

Open the catalog to page 2

Torque characteristic curve I = 1,7 A/Ph 85000-230180 Torque characteristic curve 85000-340820 Torque characteristic curve

Open the catalog to page 3

85000-10 Stepper motors with integrated positioning control D1 When selecting a suitable motor, using just the retaining torque is not enough, as the motor’s torque decreases with the speed. It is therefore essential to select the correct motor according to the torque curve. Actuation via single I/O interface, 31 position configurations and call-ups. Control unit can be parametrised quickly and conveniently with the software. The software and manual for programming the positioning control are available as free download. Note: Stepper motor with integrated positioning control. It forms a...

Open the catalog to page 4

Stepper motors with integrated positioning control 85000-10-340820 Input 1 (binary 0) Input 2 (binary 1) Input 3 (binary 2) Input 4 (binary 3) Supply converter TxD RxD n.c. 16-pin M23 plug, supply voltage/digital I/O +24 V to +36 V DC control voltage n.c. +24 V to +60 V DC motor voltage GND Output "Motor standing" (MOST) Output "Ready" (RDY) Input "Start" or "Frequency" n.c. Input I5, or direction, or reference point or analog value n.c. n.c. Input 1 (binary 0) Input 2 (binary 1) Input 3 (binary 2) Input 4 (binary 3) n.c. Digital I /O BAC Motor supply +24 V to +48 V DC Control voltage...

Open the catalog to page 5

85000-10 Stepper motors with integrated positioning control 85000-10-170043 Torque characteristic curve 48V 85000-10-230200 Torque characteristic curve 1,8 85000-10-340820 Torque characteristic curve

Open the catalog to page 6

Stepper motors with integrated positioning control B D D1 D2 D3 E H L1 L3 L4 L5 L6 S Control voltage Motor voltage VDC VDC Moment of inertia kgcm² Order No. Current reduction Inputs Outputs Step resolution INTEGRATED FOR MONITORING THE POSITION INTEGRATED FOR MONITORING THE POSITION INTEGRATED FOR MONITORING THE POSITION

Open the catalog to page 7

85000-15 Accessories for stepper motors with integrated positioning control Sample order: nlm 85000-15-92 Note: The stepper motor has a dialog interface for configuration via a superordinate computer. The controllers are configured using this interface. The standard interface is executed as a TTL interface. A converter (USB converter) must therefore be used so that the stepper motor can be configured via a PC (with the help of the programming software) or controlled remotely. To prevent the controller from being destroyed by excessive differences in potential or compensating currents, the...

Open the catalog to page 8

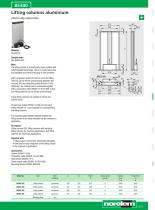

Lifting columns aluminium 48 electrically adjustable Material: Aluminium. Note: The lifting column is an electrically driven system with fully integrated technology, which is maintenance-free and operated according to the plug & work principle. With a maximum speed of 8 mm/s, up to two lifting columns can be driven synchronously between 355 mm and 500 mm using the control (85300-10-90). Optionally, two controls can be connected together with a connection cable (85300-10-91X1000) so that four lifting columns can be driven synchronously. These lifting columns are suitable for thrust and...

Open the catalog to page 9

85300-10 Controls for lifting columns 2 Note: Controls to operate lifting columns 85300. Up to two drives can be connected to the controls. The controls can be operated by a hand switch with LCD display 85300-15-01.Two controls can be connected together with connection cable 85300-10-91X1000 so that four lifting columns can be driven synchronously. On request: Power supply cable (Swiss version). Power supply cable (UK version). Power supply cable (Japanese version). Power supply cable (USA version). Accessories: Connection cable 85300-10-91X1000 Power supply cable 85300-10-92X1800 Hand...

Open the catalog to page 10

Hand switch for lifting columns Note: Hand switch to operate the control 85300-10-90 and adjust lifting columns 85300. Lifting columns 85300 are operated intuitively using the hand switch with display (85300-15-1). Intermediate positions can also be stored and switched between different users. The hand switches can be fixed to a table using hand switch drawer 85300-15-91. Accessories: Hand switch drawer 85300-15-91 Function keys Hand switch with display Hand switch drawer

Open the catalog to page 11All Norelem - Éléments standard mécaniques catalogs and technical brochures

-

Assembly system

72 Pages

-

Pneumatic cylinder

9 Pages

-

Drive technology

235 Pages

-

Tube connectors - Tube columns

59 Pages

-

Concentricity elements

10 Pages

-

Connectors Energy chains

18 Pages

-

Power supply units

3 Pages

-

Sensor technology

4 Pages

-

Material handling and transport

45 Pages

-

technoshop

38 Pages

-

BROCHURE TELESCOPIC SLIDES 2021

88 Pages

-

PRODUCT OVERVIEW EDITION 2022

43 Pages

-

THE BIG GREEN BOOK edition 2022 vol.2

1336 Pages

-

THE BIG GREEN BOOK edition 2022 vol.1

1380 Pages

-

Guide rails norelem

20 Pages

-

ALUMINIUM PROFILES

104 Pages

Archived catalogs

-

01250

2 Pages

-

01148 Subplates

1 Pages

-

Norelem Edition 2019

1986 Pages

-

THE BIG GREEN BOOK edition 2019

1986 Pages

-

THE BIG GREEN BOOK 2018

1767 Pages

-

BIG GREEN BOOK 2017

1590 Pages

-

BGB

1456 Pages

-

BIG GREEN BOOK

1 Pages

-

01148 Pallets

1 Pages

-

01127 Base plates

1 Pages

-

01060 Steel base plates

1 Pages