Website:

norelem - Éléments standard mécaniques

Website:

norelem - Éléments standard mécaniques

Group: norelem

Catalog excerpts

A wide range of guide rails for high-precision movement norelem guide rails have many uses. Whether for metrology equipment construction, or in the optical industry, or for maintenance, milling or even the creation of special machinery, norelem guide rails provide you with a versatile, qualitative and high-precision solution that can be adapted to all your needs. Overview of the norelem range 21010 Guide rail with dovetail mount with micrometric adjustment screw 21060 Guide rail with dovetail mount 21061 Guide rail with dovetail mount with end plates 21062 Guide rail with dovetail mount...

Open the catalog to page 2

Green Means Go. Find it. Get it. Go. ■ 60,000 products available from stock. ■ Technical support listening to all your questions, giving advice and assisting you in making decisions. ■ Fast and simple implemention of your ideas with our free CAD-data.

Open the catalog to page 3

HIGH PRECISION ■ High-precision geometry ■ Slide guide with integrated adjusting device Integrated modular grid ■ Screw preservation, thanks to the end plate Micrometric adjustment screw ■ Adapted for challenging environments Ground surfaces Grease nipple ■ High load rating ■ Integrated grease nipple - fully embedded for zero interference www.norelem.fr www.norelem.c

Open the catalog to page 4

WIDE RANGE ■ Versatile range, adapted to different customer needs, movement speeds and load ratings; great precision; reduced weight ■ Two different designs: grey cast iron, and black anodised aluminium ■ Product bearing the norelem logo – visual and tactile quality ■ Guide rails with dovetail mounts are economical and have a higher load rating ■ Roller mounted guide rails benefit from greater smoothness and a higher level of accuracy ■ Aluminium guide rails with dovetail mounts are an excellent compromise between weight, resilience and precision WIDE-RANGING POSSIBILITIES ■ Modular grid...

Open the catalog to page 5

21010 Dovetail slides with micrometer spindle and location holes E E1 Advantages: An additional centring hole is located at all tapped holes. Other connecting elements can be precisely mounted on the slide in combination with our centring rings 20240. Quick and retrofit combination in the X, Y and Z axes. M1 = counterbore for screw. TI = number of fastening holes E1/E2/M1 inside. TA = number of fastening holes E/E1/MA outside. Version: Black anodised. Note: These precision dovetail slides find use in machine and fixture construction, metrology, optical instruments and fine mechanics. The...

Open the catalog to page 6

Dovetail slides with location holes Material: EN-GJL-250. Version: Bright, ground. Sample order: nlm 21060-050080 Note: These high-precision carriage guides are used to build machines and mechanical systems, metrology devices for the optical industry and in precision mechanical engineering, for example. The central set screw M1 can be replaced by a clamping lever 06460. The stated permissible load values (F) are designed for dynamic loads with a service life of 1 million lifting operations. For static loads, 10 times the table value F is permitted. The torque values apply only to centred...

Open the catalog to page 8

with location holes

Open the catalog to page 9

Dovetail slides with end plates and location holes Material: EN-GJL-250. Version: Bright, ground. Sample order: nlm 21061-050080 Note: These high-precision carriage guides are used to build machines and mechanical systems, metrology devices for the optical industry and in precision mechanical engineering, for example. The central set screw M1 can be replaced by a clamping lever 06460. The stated permissible load values (F) are designed for dynamic loads with a service life of 1 million lifting operations. For static loads, 10 times the table value F is permitted. The torque values apply...

Open the catalog to page 10

with end plates and location holes

Open the catalog to page 11

Dovetail slides with micrometer spindle and location holes Material: EN-GJL-250. Version: Bright, ground. Sample order: nlm 21062-050080 Note: These high-precision carriage guides are used to build machines and mechanical systems, metrology devices for the optical industry and in precision mechanical engineering, for example. The central set screw M1 can be replaced by a clamping lever 06460. The stated permissible load values (F) are designed for dynamic loads with a service life of 1 million lifting operations. For static loads, 10 times the table value F is permitted. The torque values...

Open the catalog to page 12

with micrometer spindle and location holes

Open the catalog to page 13

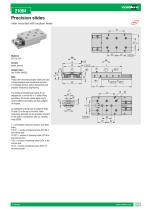

21064 Precision slides roller mounted with location holes Material: EN-GJL-250. Version: Bright, ground. An additional centring hole is located at holes D2 and D3 on the top of the slide. Other connecting elements can be precisely mounted on the slide in combination with our centring rings 20240. The stated permissible load values (F) are designed for a service life of 1 million lifting operations. The torque values apply only to centred slides.Cross slides are also available on request. Note: These roller-mounted precision slides are used to build machines and mechanical systems, in...

Open the catalog to page 14

roller mounted with location holes

Open the catalog to page 15

21068 Precision slides roller mounted with end plates and location holes Version: Bright, ground. L3 An additional centring hole is located at holes D2 and D3 on the top of the slide. Other connecting elements can be precisely mounted on the slide in combination with our centring rings 20240. Note: These roller-mounted precision slides are used to build machines and mechanical systems, in metrology devices, optical instruments and precision mechanical engineering. The stated permissible load values (F) are designed for a service life of 1 million lifting operations. The torque values apply...

Open the catalog to page 16

roller mounted with end plates and location holes

Open the catalog to page 17

21070 Precision slides roller mounted with micrometer spindle and location holes E1 Version: Bright, ground. An additional centring hole is located at holes D2 and D3 on the top of the slide. Other connecting elements can be precisely mounted on the slide in combination with our centring rings 20240. The stated permissible load values (F) are designed for a service life of 1 million lifting operations. The torque values apply only to centred slides. Note: These roller-mounted precision slides are used to build machines and mechanical systems, in metrology devices, optical instruments and...

Open the catalog to page 18All Norelem - Éléments standard mécaniques catalogs and technical brochures

-

Assembly system

72 Pages

-

Pneumatic cylinder

9 Pages

-

Drive technology

235 Pages

-

Tube connectors - Tube columns

59 Pages

-

Concentricity elements

10 Pages

-

Connectors Energy chains

18 Pages

-

Power supply units

3 Pages

-

Sensor technology

4 Pages

-

Motors - Lifting columns

11 Pages

-

Material handling and transport

45 Pages

-

technoshop

38 Pages

-

BROCHURE TELESCOPIC SLIDES 2021

88 Pages

-

PRODUCT OVERVIEW EDITION 2022

43 Pages

-

THE BIG GREEN BOOK edition 2022 vol.2

1336 Pages

-

THE BIG GREEN BOOK edition 2022 vol.1

1380 Pages

-

ALUMINIUM PROFILES

104 Pages

Archived catalogs

-

01250

2 Pages

-

01148 Subplates

1 Pages

-

Norelem Edition 2019

1986 Pages

-

THE BIG GREEN BOOK edition 2019

1986 Pages

-

THE BIG GREEN BOOK 2018

1767 Pages

-

BIG GREEN BOOK 2017

1590 Pages

-

BGB

1456 Pages

-

BIG GREEN BOOK

1 Pages

-

01148 Pallets

1 Pages

-

01127 Base plates

1 Pages

-

01060 Steel base plates

1 Pages