Website:

norelem - Éléments standard mécaniques

Website:

norelem - Éléments standard mécaniques

Group: norelem

Catalog excerpts

Drive technology

Open the catalog to page 1

Technical Information for toothed belts 22052, 22054, 22057 and 22059 General Our toothed belts are made of abrasion-resistant polyurethane and reinforced with hightensile steel cording. They allow for a smooth and synchronous transmission of power. They are maintenance-free and extremely cost-efficient. Drive installation Diagrams and performance tables are available on these pages for selecting the size. The axles must be parallel to one another. It is possible to align the toothed pulleys very precisely using a straight edge or laser. Use the largest possible toothed pulleys. Make sure...

Open the catalog to page 2

Technical information for toothed belts 22052 and 22057 12 for calculating max. permissible engaging teeth Nr. of teeth of small gear wheel Belt width [cm] Centre distance [mm] Power [kW] Torque [Nm] Specific power Specific torque Engaging teeth of small gear wheel Specific tooth force Output “P” and torque “M” to be transferred via the belt are calculated using the following formulas: P spez M spez [ Ncm/cm ] [ W/cm ] M spez P spez [ Ncm/cm ] [ W/cm ] M spez P spez [ Ncm/cm ] [ W/cm ] M spez P spez [ Ncm/cm ] [ W/cm ] M spez P spez [ Ncm/cm ] [ W/cm ] M spez P spez [ Ncm/cm ] [ W/cm ] M...

Open the catalog to page 3

Technical information for toothed belts 22052 and 22057 b Belt width Belt length Number of belt teeth Centre distance Effective centre distance Outer diameter Outer diameter of small pulley Pulley width Effective diameter of small pulley Effective diameter of large pulley Effective diameter Outer diameter of large pulley Pre-tensioning force per belt Maximum permissible belt tension Peripheral force Acceleration time Deceleration time Speed / peripheral speed Number of teeth in mesh Number of teeth on small pulley Number of teeth on large pulley Static shaft power Drive pulley speed Angular...

Open the catalog to page 4

Technical information for toothed belts 22052 and 22057 Calculating the number of teeth in mesh For speed step-up ratios a c2 acceleration factor must be anticipated: i = from 0.66 to 1.0 c2 = 1.1 i = from 0.40 to 0.66 c2 = 1.2 i < 0.40 c2 = 1.3 The overall service factor is: c0 = c1 x c2 Belt and washer selection Use the selection diagram for belt pre-selection. Selecting the largest permissible pulley is recommended. Calculating speed ratio i n1 with ˆ [°] = wrap angle t ˘ (z g - zk ) ˆ = 2 ˘ arccos ˘ 2˘ ˘A Determining the belt width b = Checking the permissible belt tension The...

Open the catalog to page 5

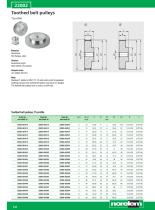

22002 Toothed belt pulleys T profile A Material: Aluminium. Rim flanges, steel. Version: Aluminium bright. Steel electro zinc-plated. Sample order: nlm 22002-051010 Note: Standard T-profile to DIN 7721 T2 with metric pitch (trapezoidal toothing). At least one toothed belt pulley must have rim flanges. The toothed belt pulleys have a centre or pilot hole. Toothed belt pulleys, T5 profile Order No. belt width 10 Order No. belt width 16 Order No. belt width 25

Open the catalog to page 6

22002 Toothed belt pulleys Toothed belt pulleys, T10 profile Order No. Form belt width 32 - Order No. Order No. belt width 16 belt width 25

Open the catalog to page 7

22003 Toothed belt pulleys AT profile A Material: Aluminium. Rim flanges, steel. Version: Aluminium bright. Steel electro zinc-plated. Sample order: nlm 22003-051012 Note: Standard AT profile with metric pitch (trapezoidal toothing). At least one belt pulley must have a rim flange. The toothed belt pulleys are centre bored or pre-drilled. The pulleys may be recessed on the sides. Toothed belt pulleys, AT5 profile Order No. belt width 10 Order No. belt width 16 Order No. belt width 25

Open the catalog to page 8

22003 Toothed belt pulleys Toothed belt pulleys, AT10 profile Order No. Order No. belt width 16 belt width 25 Order No. Form belt width 32

Open the catalog to page 9

22004 Toothed pulleys profile HTD 5M G Material: Steel. Toothed pulleys without aluminium rim flanges. Version: Steel phosphated. Aluminium bright. Sample order: nlm 22004-051512 Note: Standard HTD profile with metric pitch (rounded toothing). At least one toothed belt pulley must have a rim flange. The toothed belt pulleys are centre bored or pre-drilled. The pulleys may be recessed on the sides. Order No. belt width 15 Order No. belt width 25 Main material

Open the catalog to page 10

22004 Toothed pulleys profile HTD 8M Material: Steel or grey cast iron. Version: Phosphated Note: Standard HTD profile with metric graduation (rounded toothing). At least one toothed belt pulley must have a rim flange. The toothed belt pulleys are centre bored or pre-drilled. belt width grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron

Open the catalog to page 11

22004 Toothed pulleys profile HTD 8M B belt width grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron

Open the catalog to page 12

22004 Toothed pulleys profile HTD 8M I belt width grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron grey cast iron

Open the catalog to page 13

22005 Toothed pulleys profile HTD 5M, for assembly with taper clamping bushes L Material: Steel or grey cast iron. Version: Phosphated Note: Standard HTD profile with metric pitch (rounded toothing). At least one toothed belt pulley must have a rim flange. Conical hole for taper clamping bushes. The taper clamping bushes must be ordered separately and are available for various shaft diameters. Pulleys with a taper hole are statically balanced as per ISO 1940 grade G16. Accessories: Taper clamping bushes 23200. belt width Main material grey cast iron grey cast iron grey cast iron grey cast...

Open the catalog to page 14

22005 Toothed pulleys profile HTD 8M, for assembly with taper clamping bushes B Material: Cast Iron. Note: Standard HTD profile with metric pitch (rounded toothing). At least one toothed belt pulley must have a rim flange. Conical hole for taper clamping bushes. The taper clamping bushes must be ordered separately and are available for various shaft diameters. Pulleys with a taper hole are statically balanced as per ISO 1940 grade G16. Version: Phosphated Accessories: Taper clamping bushes 23200.

Open the catalog to page 15All Norelem - Éléments standard mécaniques catalogs and technical brochures

-

Assembly system

72 Pages

-

Pneumatic cylinder

9 Pages

-

Tube connectors - Tube columns

59 Pages

-

Concentricity elements

10 Pages

-

Connectors Energy chains

18 Pages

-

Power supply units

3 Pages

-

Sensor technology

4 Pages

-

Motors - Lifting columns

11 Pages

-

Material handling and transport

45 Pages

-

technoshop

38 Pages

-

BROCHURE TELESCOPIC SLIDES 2021

88 Pages

-

PRODUCT OVERVIEW EDITION 2022

43 Pages

-

THE BIG GREEN BOOK edition 2022 vol.2

1336 Pages

-

THE BIG GREEN BOOK edition 2022 vol.1

1380 Pages

-

Guide rails norelem

20 Pages

-

ALUMINIUM PROFILES

104 Pages

Archived catalogs

-

01250

2 Pages

-

01148 Subplates

1 Pages

-

Norelem Edition 2019

1986 Pages

-

THE BIG GREEN BOOK edition 2019

1986 Pages

-

THE BIG GREEN BOOK 2018

1767 Pages

-

BIG GREEN BOOK 2017

1590 Pages

-

BGB

1456 Pages

-

BIG GREEN BOOK

1 Pages

-

01148 Pallets

1 Pages

-

01127 Base plates

1 Pages

-

01060 Steel base plates

1 Pages