Catalog excerpts

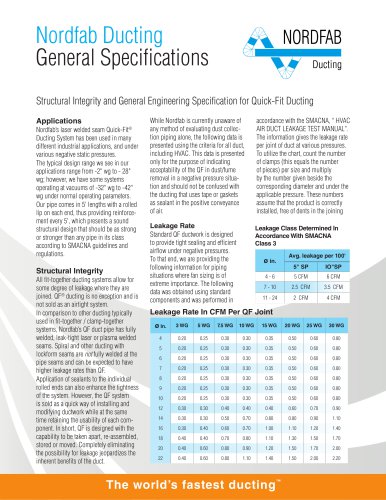

Nordfab Ducting General Specifications Structural Integrity and General Engineering Specification for Quick-Fit Ducting Applications Nordfab’s laser welded seam Quick-Fit Ducting System has been used in many different industrial applications, and under various negative static pressures. The typical design range we see in our applications range from -2" wg to - 28" wg; however, we have some systems operating at vacuums of -32" wg to -42" wg under normal operating parameters. Our pipe comes in 5' lengths with a rolled lip on each end, thus providing reinforcement every 5', which presents a sound structural design that should be as strong or stronger than any pipe in its class according to SMACNA guidelines and regulations. ® Structural Integrity All fit-together ducting systems allow for some degree of leakage where they are joined. QF® ducting is no exception and is not sold as an airtight system. In comparison to other ducting typically used in fit-together / clamp-together systems, Nordfab’s QF duct pipe has fully welded, leak-tight laser or plasma welded seams. Spiral and other ducting with lockform seams are not fully welded at the pipe seams and can be expected to have higher leakage rates than QF. Application of sealants to the individual rolled ends can also enhance the tightness of the system. However, the QF system is sold as a quick way of installing and modifying ductwork while at the same time retaining the usability of each component. In short, QF is designed with the capability to be taken apart, re-assembled, stored or moved. Completely eliminating the possibility for leakage jeopardizes the inherent benefits of the duct. While Nordfab is currently unaware of any method of evaluating dust collection piping alone, the following data is presented using the criteria for all duct, including HVAC. This data is presented only for the purpose of indicating acceptability of the QF in dust/fume removal in a negative pressure situation and should not be confused with the ducting that uses tape or gaskets as sealant in the positive conveyance of air. accordance with the SMACNA, “ HVAC AIR DUCT LEAKAGE TEST MANUAL”. The information gives the leakage rate per joint of duct at various pressures. To utilize the chart, count the number of clamps (this equals the number of pieces) per size and multiply by the number given beside the corresponding diameter and under the applicable pressure. These numbers assume that the product is correctly installed, free of dents in the joining Leakage Rate Standard QF ductwork is designed to provide tight sealing and efficient airflow under negative pressures. To that end, we are providing the following information for piping situations where fan sizing is of extreme importance. The following data was obtained using standard components and was performed in Leakage Class Determined In Accordance With SMACNA Class 3 Leakage Rate In CFM Per QF Joint ø In.

Open the catalog to page 1

Nordfab Ducting General Specifications ends, and that the gasket is in place. Special gasket material and sealants will increase the sealing capabilities. Manufacturing Profile Nordfab Americas manufactures QuickFit Ducting in Thomasville NC, USA. Nordfab QF duct is a clamp-together design using a rolled edge design with a single lever clamp. The ducting and clamps are constructed from similar materials. All clamps contain a standard gasket made of Nitrile which is suitable for most applications, including oil mist, as long as high temperatures are not an issue. Silicone and ePTFE gasket...

Open the catalog to page 2

Nordfab Ducting General Specifications i. Buna-N, ASTM D2000 MBC610, 60 Durometer Hardness, with a temperature rating of 250°F maximum and is black in color, used with the Quick-Fit Sleeve. ii. Silicone rubber, ASTM D2000 MGE705, 70 Durometer Hardness, and is red in color, used with the Quick-Fit Sleeve. f. Sealing gaskets iii. Molded gaskets shall meet the material classification of ASTM D-2000 M2BG510 A24 B34 EO14 EO34 EF11 EF21 and used in systems where the temperature rating is 225°F or less and are black in color. This component shall be made using conductive materials for...

Open the catalog to page 3All Nordfab catalogs and technical brochures

-

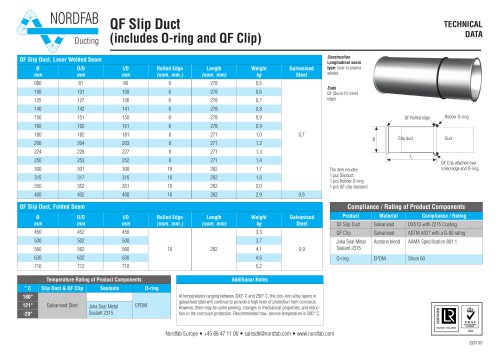

QF Slip Duct

1 Pages

-

QF DATA ® & QFS Duct

1 Pages

-

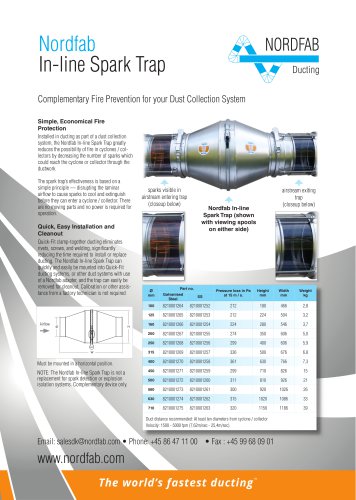

Nordfab In-line Spark Trap

1 Pages

-

Nordfab QF Ball Joint

1 Pages

-

23mm Mild Steel

12 Pages

-

Pipe System

12 Pages

-

Duct System

24 Pages

-

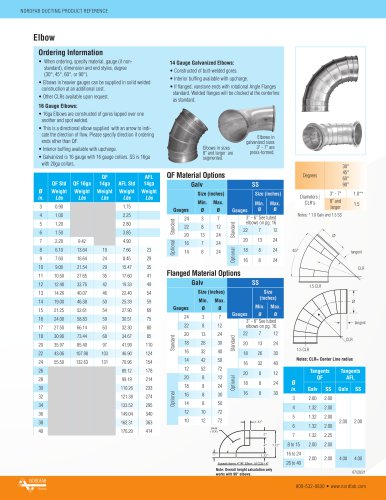

Elbow

3 Pages

-

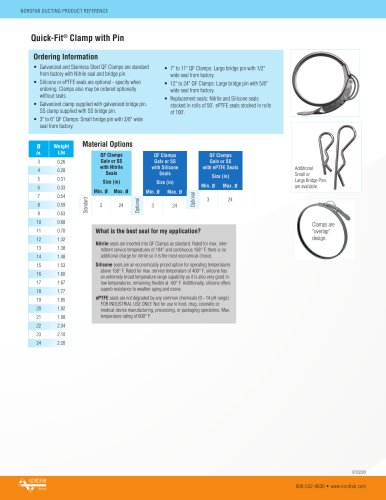

Quick-Fit® Clamp with Pin

1 Pages

-

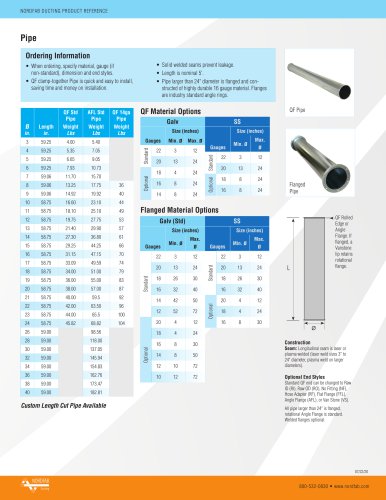

Pipe

1 Pages