Website:

Nippon Gear

Website:

Nippon Gear

Catalog excerpts

Screw Jack Self-locking characteristic: Since it has a self-locking function due to the adoption of trapezoidal thread of an optimum lead, this screw jack does not need any braking mechanism in the driving shaft system. Fixed quantity operating characteristic: This screw jack permits fixed quantity operation because the adoption of high-accuracy worm and screw makes it possible to obtain a lifting screw lead proportionated to the amount of rotation of the input shaft. Anti-backlash type is also available for uses in which hysteresis must be avoided. Interlocking characteristic: Since the...

Open the catalog to page 2

Common items Screw jack Ball screw jack Selection of jack size No. Basic specifications Lifting load/lifting screw speed graphs Allowable buckling load Allowable side force Drawings of outside dimensions Traveling nut type jack Jack with hand wheel, Jack with motor Bevel gear-type jack Basic specifications Lifting load/lifting screw speed graphs Allowable buckling load Expected traveling distance Drawings of outside dimensions Traveling nut type jack Geared limit switch Setting direction symbols Geared limit switch setting procedure Braking device Jack system Jack with trunnion base...

Open the catalog to page 3

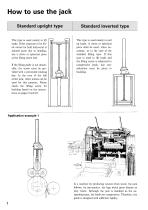

Standard upright type Standard inverted type This type is used mainly to lift loads. If the structure to be lift- ed cannot be held horizontal at joinned parts due to bending, use a clevis or spherical piece If the lifting guide is not detain- able, the screw must be pro- vided with a prevented rotating screw jack, other means can be used for this purpose. Please check the lifting screw for buckling based on the instruc- This type is used mainly to pull up loads. A clevis or spherical piece shall be used, when ne- standard lifting type. If this type is used to lift loads and the lifting...

Open the catalog to page 4

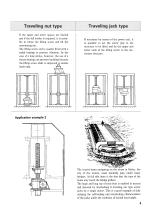

Traveling jack type If the upper and lower spaces are limited and if the full stroke is required, it is possi- ble to rotate the lifting screw and lift the The lifting screw end is usually fitted with a radial bearing to prevent vibration. In the case of a long stroke, however, the use of a thrust bearing can prevent buckling because the lifting screw shaft is subjected to tensile If necessary by reason of the power unit, it is possible to set the screw jack to the structure to be lifted and fix the upper and lower ends of the lifting screw to the sta- tionary structure. The tourist boats...

Open the catalog to page 5

Selection of jack size No. [Calculation example] Specification Required jack performance Select temporarily the size No. of the screw jack having the standard capacity to meet the load. Load at the time of lifting: 30 kN Lifting speed: 1000 mm/min. Select temporarily J2G and obtain the input shaft min-1 “n” assuming the worm reduction ratio as “H”. Formula (1) n Assume the worm reduction ratio as"H"and obtain the required input shaft rpm from the lifting speed. Set the hand wheel radius if the screw jack is to be used for manual operation. If low speed or fine adjustment is specially...

Open the catalog to page 6

When you purchase our jack, please order it by product code No. Note (2): If the jack is provided with a geared limit switch or RC encoder, specify the direction of its setting according to the figures on page 26.

Open the catalog to page 7

Capacity Lifting screw diameter and lead Maximum allowablepower per jack Worm gear ratio Required input at allowable load Maximum input at allowable load Allowable maximum input (Without prevent key) kg (With prevent key) Grease charging quantity Prevent key torque Input shaft allowable overhang load Input shaft no load torque b Troque coefficient Speed coefficient c (screw lead per rotation of input shaft) Lifting screw forming Roll threading Rigid PVC Lifting screw cover material Machining Steel Remarks: 1) If the screw jack is used at input 1,000 min-1 or over, oil Iubrication is...

Open the catalog to page 8

The size No. can be selected from the graph based on the lifting load and lifting screw speed. Lifting screw speed (mm/min) Lifting screw speed (mm/min)

Open the catalog to page 9

Allowable buckling load Shaft end free (plain end) Shaft support length (mm) A wire 5 mm diameter can be used to suspend a load of one ton without re- gard to length. If, therefore, screw jacks are so designed that the lifting screws are subjected to tensile loads, there is no fear of buckling. This de- sign is preferable economically also. When it is unavoidable to use your jack for compressive loads, please se- lect the size No. based on the allow- able values shown here. It is also possible to avoid buckling by adopting the traveling nut type. Please consult Per = allowable buckling load...

Open the catalog to page 10

Allowable side force Screw jack Allowable side force of lifting-type screw jack: N (If bellows are used, the values for one size No. above are applicable. side force Suppose, for example, screw jacks are used on a transfer car lifting a load, as shown in this figure. The transfer car will repeat acceleration, deceleration and stop. If the jacks are operated also during acceleration and deceleration, the allowable side force should be checked from the above tables using the value of the side for- however, the jacks are operated only while the transfer car is at rest, the side force is...

Open the catalog to page 11

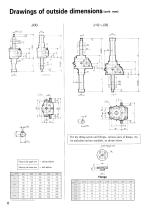

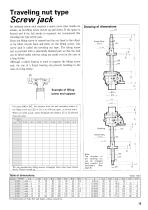

Drawings of outside dimensions — with bellows

Open the catalog to page 12

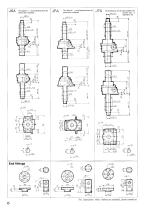

6 A The values in ( ) are dimensions when the JpA The values in ( ) are dimensions when the vj 7 A The dimensions are the same whether the For dimensions when bellows are attached, please consult us.

Open the catalog to page 14

Screw jack An ordinary screw jack requires a space more than double its stroke, as its lifting screw moves up and down. If the space is limited and if the full stroke is required, we recommend this traveling nut type screw jack. Since the lifting screw is rotated and the nut fixed to the object to be lifted travels back and forth on the lifting screw, this screw jack is called the traveling nut type. The lifting screw end is provided with a spherically finished part so that the load can be lifted stably without using any guide even in the case of Although a radial bearing is used to support...

Open the catalog to page 15All Nippon Gear catalogs and technical brochures

-

Gears

2 Pages

-

LSB

2 Pages

-

Jacks Lineup

8 Pages

-

Company Profile

12 Pages

-

Valve Actuator Products Guide

16 Pages

-

JPQ series

8 Pages

-

SMB Series

24 Pages