Catalog excerpts

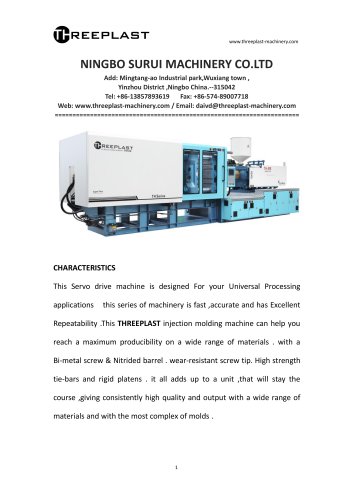

NINGBO SURUI MACHINERY CO.LTD Add: Mingtang-ao Industrial park,Wuxiang town , Yinzhou District ,Ningbo China.--315042 Tel: +86-13857893619 Fax: +86-574-89007718 Web: www.threeplast-machinery.com / Email: daivd@threeplast-machinery.com ===================================================================== Characteristics This Servo drive machine is designed For your PVC products Processing applications . this series of machinery is fast ,accurate and has Excellent Repeatability .This THREEPLAST injection molding machine can help you reach a maximum producibility on PVC materials . with a electroplating screw & barrel . wear-resistant screw tip. High strength tie-bars and rigid platens . it all adds up to a unit ,that will stay the course ,giving consistently high quality and output with PVC material and with the most complex of molds .

Open the catalog to page 1

High Speed Valve Response , reliable continual operation and optimum energy savings . Excellent Wear-Resistant , corrosion resistant screw & barrel for the processing of materials with fiber additives and also fire retardant materials . Screw Driven by high torque ,variable speed ,radial piston motor. PID Temperature Control insures an accuracy of +/-1 ℃ ,thus the fluctuation of the temperature is very minimal . Cushion Monitoring can help the operator to check the quality of the product. I.e. if the injection end position is under the allowed tolerance that means that the product is within...

Open the catalog to page 2

1.Larger space between tie-bars, suitable for larger molds and multi-cavity needs. 2.Longer and wider guide length, higher repeatability precision, improve product quality and mold lifespan. 3.Better designed mechanical structure and toggle system faster cycle time, and improve production efficiency. 4.Upgraded parts, Graphite-copper bushes and slider used on tie-bar, ejector and movable platen, ensure fast and precise mold close and open. 5.European type ejector structure, larger space, convenient for maintenance. 6.Prepared enough space for upgrade and retrofits 7.Integrated and...

Open the catalog to page 3

8.Much higher rigidity mechanical system, not only .improves machine's lifespan, but also can protect mold. 2. Injection Unit 1.Full supported injection unit with dual precise linear guide rails, ensure the best precision and fast start speed. ( Above 350T machine is Rod guide ) 2.Dual carriage cylinders improve a better injection precision. 3.Injection unit steel pipes adopt pipe fitting to connect, no welding design ensure maintenance and after-service to be easier. 4.Upturning designed nozzle cover, production and maintenance to be easier. 5.Double-layer designed barrel cover to avoid...

Open the catalog to page 4

6.Imported high quality SKD61 material screw tip, check ring and thrust ring; a lot kinds of screws design can meet different plastic material and special processing injection molding needs. 7.Barrel PID controls the difference of temperature, less error. 3. Hydraulic Unit 1.Standard equipped with precise and energy saving servo motor system, energy saving capacity can reach to 20%~80% than traditional injection machine. 2.World famous brands hydraulic parts ensure machine’s reliability and fast response speed. 3.Visible and dischargeable oil tank, easy for hydraulic circuit maintenance....

Open the catalog to page 5

5.Self-sealed magnetic suction filter, make your maintenance more convenient. 6.Logical distribution of pump oil suction port, oil tank oil outlet and hydraulic pipe fits, easy for maintenance. 7.Germany DIN standard hydraulic pipe fitting with seal, G screw thread style plug, avoid oil pollution. 4. Electric Unit 1.World well-known brands electric parts. 2.High quality large color screen controller, multi-language available. 3.Standard equipped LED three-color tower light with alarm, machine working situation is clear. 4.Modernized network management function available. 5.Water-proof...

Open the catalog to page 6

Main Components

Open the catalog to page 7

1. Delivery Term: By sea 2. Loading Port: NingBo Port 3. Packing Method: Standard Export Package 4. Delivery time: Within 30 days after received advance payment. WARRANTY 1. Machine Hydraulic part & Mechanical part warranty Period of two years . (include : casting ,tie-bars ,injection ,clamping & ejector manifolds ,toggle links and carriage guide rod , Hydraulic hoses , position sensor , bushings, toggle pins, Hydraulic valves, proportional valve, Hydraulic screw motor and hydraulic pump ) 2. Screw &Barrel warranty Period of 12 months . (new plastic material ) 3. Electronic components...

Open the catalog to page 9

Factory Glance

Open the catalog to page 11All Ningbo SuRui Machinery Co. catalogs and technical brochures

-

Drying hopper TH-H series

8 Pages

-

Knife mill TH-F series

8 Pages

Archived catalogs

-

TH-WCI, TH-ACi series

2 Pages