Website:

Nilfisk

Website:

Nilfisk

Group: Nilfisk Group

Catalog excerpts

Compressed-air and electric pneumatic conveyors Pneumatic Conveyors: automation is in the air

Open the catalog to page 1

Nilfisk: the world’s leading pneumatic conveyor manufacturer Nilfisk, operating in 70 countries, is a leading manufacturer of industrial cleaning machinery; apart from being a leading manufacturer of “industrial vacuum cleaners”, it designs and manufactures also pneumatic conveyors. Nilfisk pneumatic conveyor department offers technical support, design, production and after-sale services; a comprehensive structure which cooperates with entrepreneurs all over the world who wish to be in full control of their production and to make powder, grain and capsule transport automated and more...

Open the catalog to page 2

What is a pneumatic conveyor? The pneumatic conveyor transfers powdery or granular materials within processing or manufacturing machinery. The transfer will take place according to the schedule, quantity, distance and height desired. Operating principle: a suction system creates vacuum within the hopper, allowing the material to be suctioned; then the material is discharged at the point of destination, i.e. a mixer, a packaging machine or a container. The benefits of pneumatic transfer compared to mechanical transfer are numerous: ·· the absence of mobile mechanical parts, except for the...

Open the catalog to page 3

Why choose Nilfisk pneumatic conveyors? There are several reasons why you should choose Nilfisk, one of which is that you are purchasing a comprehensive solution, and not a mere product: ·· The entire process, from the very first contact to the delivery of your system is managed by experienced professionals. ·· All inspections, feasibility studies, offers and supplies are always carried out by Nilfisk expert technicians. ·· We have a wide range of products to meet every need. ·· Nilfisk is present in 70 countries. Your advantages Your concrete and measurable advantages are the follow- Our...

Open the catalog to page 4

Fields and application areas Nilfisk pneumatic conveyors are ideal for various applications, such as pharmaceutical, food, plastic field companies, etc... They are perfectly integrated in the production process; here are some examples of the most common applications: ·· Material pick-up from bulk bags, big bags, hoppers, etc... ·· Material discharge for: ·· Pills ·· Capsules ·· Powders ·· Excipients ·· Other... ·· Sieving: the first conveyor feeds the vibrating sieve machine; the second conveyor transfers the material to the next processing step ·· Weighting: the conveyor feeds the...

Open the catalog to page 5

Operational layout - Pick-up 1. Standard pick-up: The material is collected from small containers at ground level through a probe tube inserted into the pick-up point by the operator; it is then transferred to the relevant area. 2. Loading station pick-up: The material is collected from a loading station, where the operator pours the material to be transferred; it is then transferred to the relevant area. In this way, the material is suctioned without the operator’s action. 3. Pick-up with feed adapter: The material is collected from a loading station, automatically fed by a production...

Open the catalog to page 6

Operational layout - Discharge and Filling 1. V-shaped mixer filling: The material is collected from the feeding hopper, directly connected to the Vshaped mixer, which is vacuumed by the suction unit. The process is continuous until the product pick-up unit is emptied. 2. Discharge into dosing unit: The material is collected from the feeding hopper or from the Big Bag directly, and unloaded into the dosing unit hopper. 3. Discharge into screw conveyor: The material is collected from the feeding hopper or from the Big Bag directly, and unloaded into the screw conveyor or conveyor belt. This...

Open the catalog to page 7

Compressed air pneumatic conveyors Vacuum generation within this type of pneumatic conveyor is carried out by using compressed air systems. Differently from other technologies, this system has a low noise level, high flexibility of use and it takes up less space. Thanks to the vacuum generation technology, the pump feed compressor’s energy consumption is similar to that of electric systems such as side channel blowers or vane pumps. very high level of hygiene. This range is equipped with the “S series” pump, with a capacity up to 3100 kg/h. Standard line For food, chemical and other...

Open the catalog to page 8

COAX® technology In pneumatic conveyors, vacuum is generated through an When the incoming compressed air enters the ejector (1) ejector system. Ejectors are small devices which generate a and flows within it, the nozzles (2) open thanks to the difsuction flow proportional to the incoming compressed air. ferent pressure generated, allowing the air to flow (3), thus By modifying the type of ejector, the number of stages and generating a certain vacuum. Thanks to the 3 sequential the size of the inlet, exit and suction nozzles, you can reach stages and to the special shape of the nozzles, the...

Open the catalog to page 9

Electric pneumatic conveyors Electric pneumatic conveyors generate vacuum through side channel blowers. Compliant with Regulation 1935/2004, they can also be used in the food and pharmaceutical industry. Standard line “Modular system” range For specific applications in food, chemical, pharma- Custom-made for specific applications in the food, ceutical and other industries. chemical, pharmaceutical and other industries. ·· 3VT Series - conveyor for powder mixtures up to 500 kg/h and/or grains smaller than 1 mm. No demixing of the material. ·· 9505 Series - blowing-based conveyor for empty...

Open the catalog to page 10

How to choose the right pneumatic conveyor In order to choose the best conveyor for your needs, you Operational and functional differences can be summarized need to evaluate several aspects, such as the type of mate- as follows: rial, its quantity and the level of hygiene required. * performance may vary depending on the material bulk's density and on conveying length.

Open the catalog to page 11All Nilfisk catalogs and technical brochures

-

CS7010

11 Pages

-

SR 1101

4 Pages

-

SR 1000S

4 Pages

-

SW 900

4 Pages

-

SW 750

4 Pages

-

SALTIX 10

4 Pages

-

SR 1000S

4 Pages

-

SDV

5 Pages

-

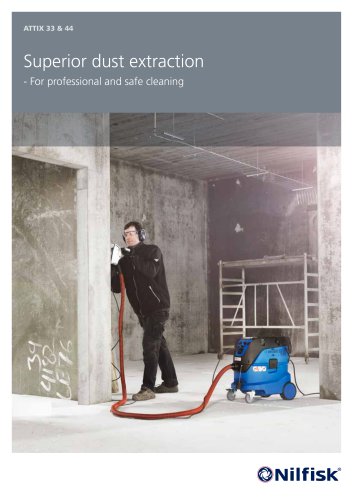

ATTIX 33 & 44

8 Pages

-

ITV1000

4 Pages

-

SW200/SW250

4 Pages

-

GD5 BATTERY

4 Pages

-

SC250

4 Pages

-

SC50

5 Pages

-

Product Catalogue 2020

192 Pages

-

Nilfisk grey line

98 Pages

-

First class power

4 Pages

-

VP600

4 Pages

-

SC6500

4 Pages

-

Floorcare and vacuum cleaners

100 Pages

-

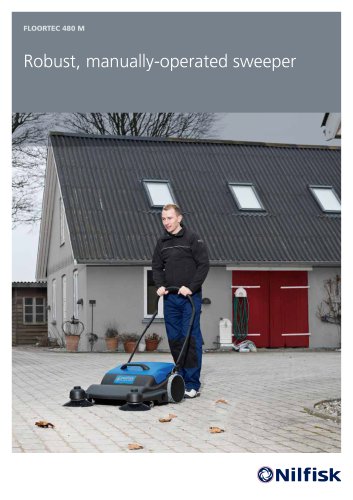

FLOORTEC 480 M

4 Pages

-

BK 900

2 Pages

-

SCRUBTEC 453

4 Pages

-

SCRUBTEC 343.2

4 Pages

-

SCRUBTEC 337.2

1 Pages

-

SCRUBTEC 234 C

4 Pages

-

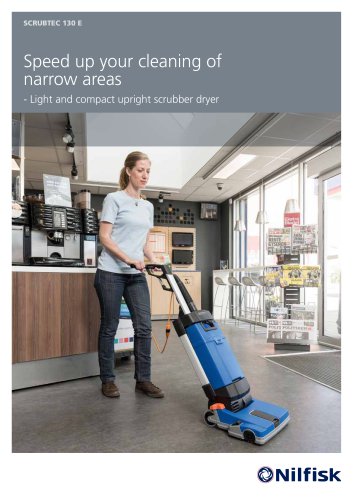

SCRUBTEC 130 E

4 Pages

-

GU 355-DUAL/455-DUAL

4 Pages

-

GU700A

2 Pages

-

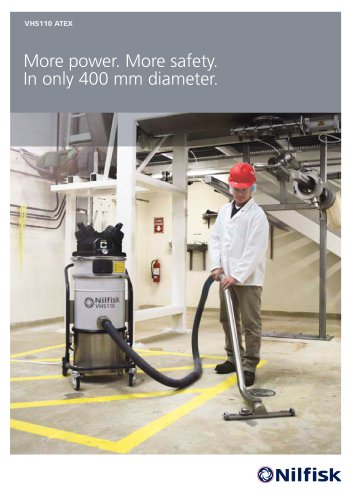

VHS110 ATEX

4 Pages

-

VU500

2 Pages

-

VP300

4 Pages

-

SW900

4 Pages

-

SW750

4 Pages

-

SC1500

4 Pages

-

SC400

4 Pages

-

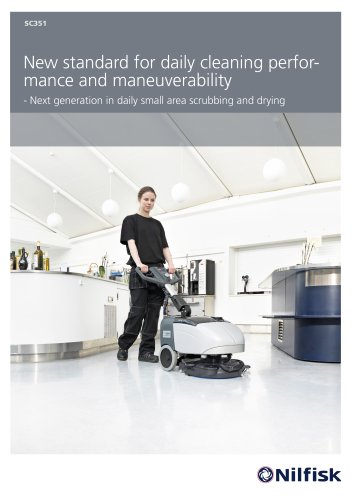

SC351

4 Pages

-

GUrange

4 Pages

-

GD5_10

4 Pages

-

FM400

4 Pages

-

BU500

2 Pages

-

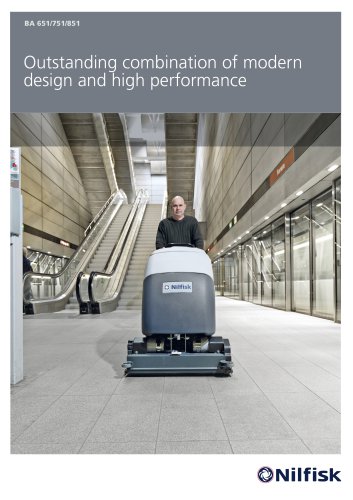

BA 651-751-851

4 Pages

-

GD930

4 Pages

-

SW5500

4 Pages

-

VLserie

6 Pages

-

SC500

4 Pages

-

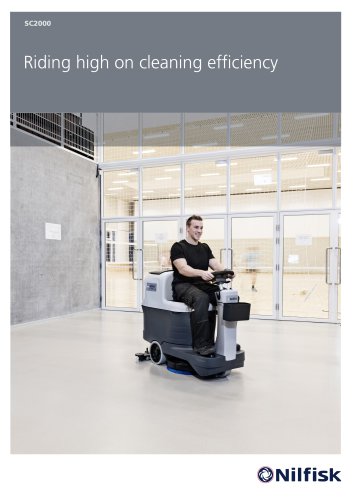

SC2000

4 Pages

-

SC100

4 Pages

-

Nilfisk grey line catalogue 2016

112 Pages

-

VP100

2 Pages

Archived catalogs

-

VP600

4 Pages

-

Product Catalogue 2015

88 Pages

-

Upright vacuum cleaners

4 Pages

-

421 C

2 Pages

-

UHR70-1700

4 Pages

-

SC450

4 Pages

-

SR 1000S

4 Pages

-

Catalogue 2014

92 Pages

-

CA 331

4 Pages

-

GD 911 BATTERY

4 Pages

-

SM 800

4 Pages

-

ER 1300/1600

4 Pages

-

cs7000

4 Pages

-

sw850

2 Pages

-

br850

4 Pages

-

855

4 Pages

-

ba755_855

4 Pages

-

sc800

4 Pages

-

CA/BA 410

4 Pages

-

uz878

2 Pages

-

Product Catalogue 2012

84 Pages

-

MX 107 C

3 Pages

-

CR1000 B

4 Pages

-

UHR 70-1700

3 Pages

-

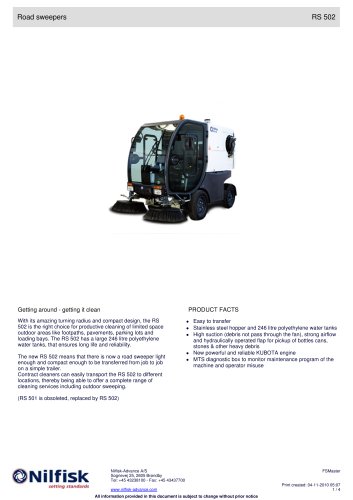

RS 502

4 Pages