Catalog excerpts

Vertical Machining Centers

Open the catalog to page 1

NSH Group worldwide ■ Headquarter NSH Group, Chemnitz, Germany a member of VDMA/VDW ■ Production Facilities HEGENSCHEIDT-MFD • Erkelenz, Germany NILES-SIMMONS • Chemnitz, Germany SIMMONS MACHINE TOOL Corp. • Albany, USA HEGENSCHEIDT-Corp. • Detroit, USA NSH-CTI • Nanchang, China WEMA GLAUCHAU • Glauchau, Germany RASOMA • Dobeln, Germany ■ Sales & Service Offices NSH RUSS Moscow • Russia NSH RUSS Nizhny Novgorod • Russia Beijing • China New Delhi • India Maubeuge • France Sao Paulo • Brazil Brisbane • Australia Guadalajara • Mexico Johannesburg • South Africa

Open the catalog to page 2

High-speed train wheels have to meet special precision requirements to ensure a smooth operation at high speeds. These requirements already formed the basis for the development of the second generation of RQQ Wheelturn machines. The RQQ vertical machines, equipped with one or two ram heads, have automatic tool changing capabilities and are primarily used to machine forged railway wheel blanks. The machines are normally integrated into auto matic production lines and are loaded by using heavy gantry robots. With the new developement of the RQMC on basis of the RQQ vertical machine, we set...

Open the catalog to page 3

The RQ Series Type RQ Fitted with one Turning Ram for machining railway wheels Type RQQ Fitted with Twin Turning Rams for machining railway wheels Type RMC Fitted with a Turn-Milling Unit for machining rotationally symmetric work pieces Type RQMC Fitted with a Turn-Milling Unit and one Turning Ram for machining rotationally symmetric work pieces

Open the catalog to page 5

Turn-Milling Unit Tool Magazine 20 Tool Pockets LH / RH An Innovative Drive Work piece Chucks Bearing Support Stator Rotor

Open the catalog to page 6

The Highlights of RQ-Baureihe Die Highlights derthe RQ Series From a vertical lathe to a vertical machining centre From heavy duty cutting to precision machining Maintenance-free, highly dynamic gearless direct drive C10 / HSK100 tool interface with maximum pull-in force and robustness for a long service life Large ram cross sections for short flow of force Configuration of faceplate drive depending on technical requirements Designed for comfortable operation using SINUMERIK Operate and a 15″ TFT touch panel NILES-HMI with customised software tools and integrated DNC...

Open the catalog to page 7

Your Benefits at a Glance - Machine with one turning ram for small-batch and single-item production Roughing and finishing combined in one machine Clamping chuck with quick jaw-change system Integrated tool and work piece probing Ready for automatic loading Low maintenance requirements Total weight depending on options approx. 37 t

Open the catalog to page 8

Your Benefits at a Glance - Production machine for automatic loading Roughing and finishing combined in one machine Integrated tool and work piece probing Process monitoring Feed control based on cutting force (AC control) Optimized chip breaking through speed modulation (ACS) Low space requirements Cooling lubricant optional up to 120 bar for long service life of the cutting plates Total weight depending on options approx. 43 t 3985

Open the catalog to page 10

Your Benefits at a Glance - Machine for finishing and complete machining Ultimate accuracy thanks to direct measuring systems in all linear and rotary axes Integrated tool and work piece measurement Use of Multi-Task Tools Extendable tool magazine Total weight depending on options approx. 37 t P-T diagram / main spindle drive S6/40% duty cycle S1/100% duty cycle P-T diagram / milling spindle

Open the catalog to page 12

Max.torque ( 60 / 100 % duty cycle ) kNm 9,1 / 8,1

Open the catalog to page 13

Your Benefits at a Glance - Machine for complete machining Ultimate accuracy thanks to direct measuring systems in all linear and rotary axes Separate units for heavy and precision machining Universal use for small and medium sized batch production Multi-technology system for universal use besides wheelset machining Total weight depending on options approx. 43 t P-T diagram / main spindle drive S6/60% duty cycle P-T diagram / milling spindle

Open the catalog to page 14

RQMC Technical specifications RQMC

Open the catalog to page 15

Your Benefits at a Glance - Project management and financing Work piece-related production and test planning Partflow and part handling concept Process simulation and process-flow control Layout and shop design Loading Zone Equipment specification and sourcing Utility planning and supply Shipping logistic planning System installation and ramp-up Performance test NILES-SIMMONS-HEGENSCHEIDT has been successfully planning and implementing production lines for leading companies in the railway and automotive industries for years. Overall responsibility is in the hands of the specialists at...

Open the catalog to page 16

Production Lines • Worldwide Finish Part Storage Chip Conveyor Work piece Flow Our project portfolio ranges from single machines with manual loading for repair shops up to highly efficient production lines with automatic gantry loading and integrated measuring and testing processes. Our specialists work in close co-operation with our customers to find the optimal solution for your specific production task based on your requirements. NSH is only one of a handful of companies worldwide to offer a complete product program for wheelset machining and, as a group, manufactures complete axle...

Open the catalog to page 17

Wheelset machining NSH Group Wheelset Diagnostic System ARGUS®II Underfloor Wheel Lathes U2000- 400 I U200-150 Mobile Wheelset Machining Lathe Mobiturn® 2 Axle deep rolling machine 7624

Open the catalog to page 18

O The NILES-SIMMONS MC-Series offers the highest flexibility in the configuration of high accuracy CNC-Turning-Milling-Drilling Centres. Variable machining components from the modular system enable complex work pieces to be completely machined in one set-up. Our intelligent hard and software tools complete your processes, from manufacturing planning through process optimization to maintenance.

Open the catalog to page 19

Aerospace Automotive and Railway and Machine BuildingIndustry Truck Industry Metro Industry Industry NILES-SIMMONS Industrieanlagen GmbH Zwickauer Str. 355 D - 09117 Chemnitz Germany Email: info.nsi@nshgroup.com Website: www.niles-simmons.de NILES CHEMNITZ

Open the catalog to page 20All Niles-Simmons Industrieanlagen catalogs and technical brochures

-

Slantbed Lathes N-Series

16 Pages

-

Machining Centres MC-Series

16 Pages

-

N60 MC

1 Pages

-

N50 MC

1 Pages

-

N40 MC

1 Pages

-

N30 MC

1 Pages

-

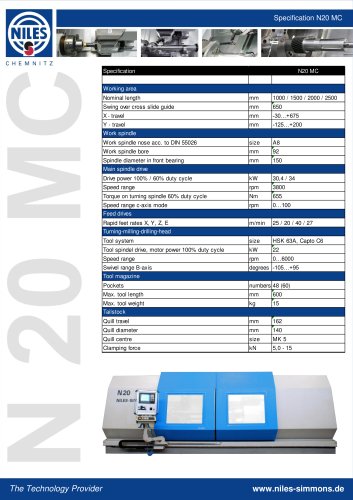

N20 MC

1 Pages

-

N40

1 Pages

-

N50

1 Pages

-

N10

1 Pages

-

N30

1 Pages

-

N20

1 Pages

-

CNC-Lathes N-Series N 50

1 Pages

-

CNC-Lathes N-Series N 40

1 Pages

-

CNC-Lathes N-Series N 30

1 Pages

-

CNC-Lathes N-Series N 20

1 Pages

-

CNC-Lathes N-Series N 10

1 Pages