Catalog excerpts

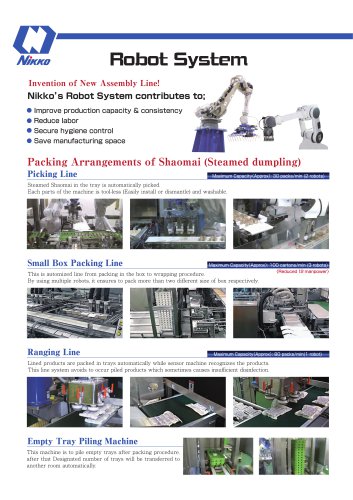

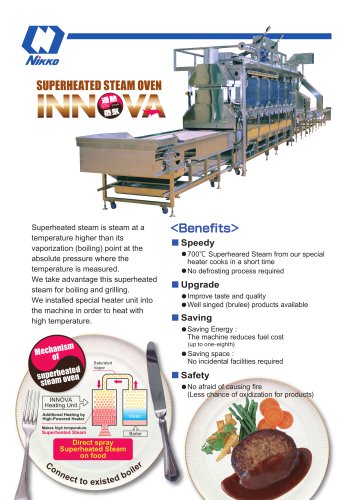

Robot System Invention of New Assembly Line! Nikko’s Robot System contributes • Improve production capacity & consistency • Reduce labor • Secure hygiene control • Save manufacturing space Picking Line Maximum Capacity (Approx): 30 packs/min (2 robots) Steamed Shaomai in the tray is automatically picked. Each parts of the machine is tool-less (Easily install or dismantle) and washable. Maximum Capacity (Approx): 100 cartons/min (3 robots) Small Box Packing Line This is automized line from packing in the box to wrapping procedure. By using multiple robots, it ensures to pack more than two different size of box respectively. Ranging Line Maximum Capacity(Approx): 80 packs/min(l robot) Lined products are packed in trays automatically while sensor machine recognizes the products. This line system avoids to occur piled products which sometimes causes insufficient disinfection. Empty Tray Piling Machine This machine is to pile empty trays after packing procedure, after that Designated number of trays will be transferred to another room automatically.

Open the catalog to page 1

What Else Can We Offer Palletizing Picking Packing Pallatizing Delta Robot, SCARA* Robot, and Multiple-Joint Robot are available to provide you customized palletizing solutions. We can offer not only sole packing process but also a whole processing line. *Stands for selective compliance assembly robot arm sSSIt is prohibited by law to copy for manufacture all and/or part of this system, These specification will be changed for improvement/modification without notice. Head office ■110-1 Tsuruno, Kushiro-shi, Hokkaido, Japan, 084-0924 TEL +81 -154-52-7101 FAX +81 -154-53-0878 International...

Open the catalog to page 2All Nikko Co. catalogs and technical brochures

-

Reducing impurities

2 Pages

-

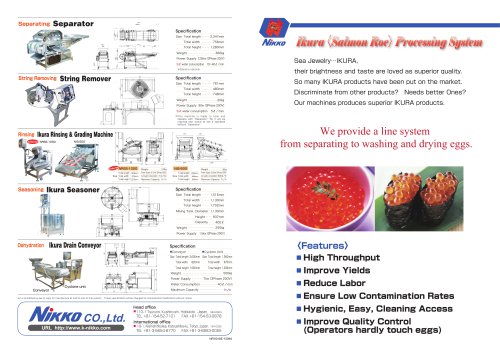

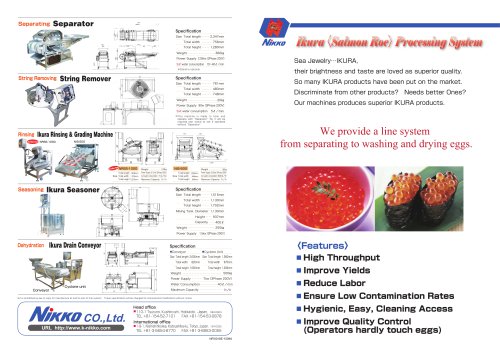

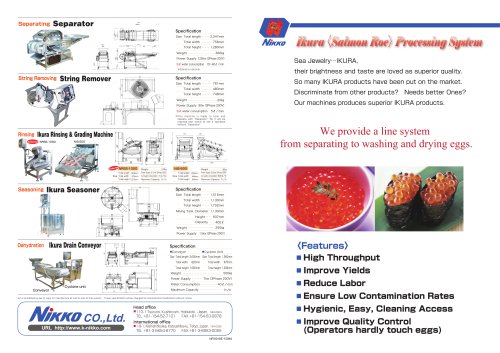

IKURA PROCESSING SYSTEM

2 Pages

-

WEDGE CUTTER

2 Pages

-

SUITOOL

2 Pages