Website:

NIHON PISCO CO., Ltd.

Website:

NIHON PISCO CO., Ltd.

Group: 株式会社日本ピスコ

Catalog excerpts

Multi-stage nozzle High Vacuum Ejector at Low Air Pressure Supply Vacuum Generator Ensuring high vacuum pressure & high vacuum flow by low 50psi air supply High vacuum pressure & flow Supply Air Vacuum level Suction flow ● Three vacuum ports are available in one unit. Pneumatic symbol P

Open the catalog to page 1

Vacuum Generator Series Vacuum Generator VVV ■ Characteristic Long life cycle and easy maintenance. Vacuum ports direction can be changed. Instruction how to change the direction of vacuum ports is mentioned following page. ● Straight or elbow silencer is available depending upon the installing space. Straight exhaust Silencer ● Digital pressure gauge is available as an option

Open the catalog to page 2

Vacuum Generator Series Vacuum Generator VVV Suction transport ▶Best suitable for a large & heavy workpiece in industries such as packaging or automobile, or suitable for an air-permeable workpiece. Vacuum packing ▶Make a vacuum state in the bag, and then packing the products, including food. Defoaming/ deaeration ▶Removing air bubbles and air contained in adhesives, cosmetics (cream), distilled water, e

Open the catalog to page 3

■ Model Designation (Example) VVV VVV E Multi-stage nozzle Vacuum generator Nozzle dia. ① . Vacuum characteristic Code Type Vacuum characteristic Digital pressure gauge Exhaust port style Air supply port size Vacuum port size E High-vacuum at low air pressure supply type E type : High-vacuum at low air pressure supply type Suction flow Air consumption Vacuum level inHg(kPa) -26.8 inHg (-90) -27.8 inHg (-94) -27.8 inHg (-94) ③ . Vacuum port size Code 12 16 1/2 ø12 ø16 (5/8" O.D.) 1/2" O.D. (ø12.7) Size Port type Push-in straight fitting and plug Remarks PC1/2-04 (3 pc.) & PP1/2 (2 pc.) incl....

Open the catalog to page 4

■ Constructions Vacuum port (V) x 3 Air supply port (P) ⬅ Exhaust port (EX) Final Vacuum VVVE27 Vacuum characteristics Final Vacuum Final Vacuum-kPa NBR Aluminum Electroless nickel-plated SPCC Nickel-plated iron PBT PVF PBT Aluminum VVVE25 Vacuum characteristics Final Vacuum Flow characteristics Nozzle cover Bracket Fastening bolt Silencer unit Element Elbow adaptor block Nozzle 3 Part O-ring Final Vacuum-kPa Electroless nickel-plated brass Aluminum − NBR Aluminum Aluminum − Electroless nickel-plated brass Aluminum Vacuum level Final Vacuum-kPa Part Nozzle 1 Body Digital Pressure Gauge (Opt

Open the catalog to page 5

Detailed Safety Instructions Before using PISCO products, be sure to read “Safety Instructions” and “Safety Instruction Manual”, Instructions for Mechanical Vacuum Switch”. Warning 1. Maintenance of vacuum generator VVV shall be carried out by a person who has sufficient knowledge of vacuum equipment and understands structure. 1. Use of vacuum filter is recommended to prevent possible entering of foreign objects from vacuum port. 2. When selecting an exhaust piping or a use without silencer with dust existing in air or pipe, dust may enter from the exhaust port by back-flow at operation...

Open the catalog to page 6

Vacuum Generator Series Vacuum Generator VVV Dimentions of push-in fitting on vacuum port (V) Dimentions of push-in fitting on air supply port (P) Model code as Tube O.D. optional attachment C1 ※Weight of the plug for vacuum port push-in fitting Plug (PP1/2) for PC1/2-04 : 2.9g Model code as Tube O.D. optional attachment C2 5 3/8 1/2 08 10 12 Install push-in fittings on vacuum ports and supply port with a wrench. The following chart is the tightening torque. Port Supply Vacuum Rc thread is same as BSPT (female thread) 2. Connection and disconnection of Tubings ①. Tubing connection Push in a...

Open the catalog to page 7

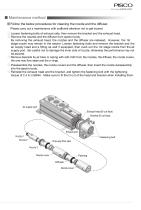

■ Follow the below procedures for cleaning the nozzle and the diffuser. Please carry out a maintenance with su ficient attention not to get injured. ① Loosen fastening bolts of exhaust side, then remove the bracket and the exhaust head. ② Remove the nozzles and the diffuser from ejector body. By removing the exhaust head, the nozzles and the diffuser are released. However, the 1st stage nozzle may remain in the ejector. Loosen fastening bolts and remove the bracket and the air supply head and a fitting as well if equipped, then push out the 1st stage nozzle from the air supply port. Be...

Open the catalog to page 8

Vacuum Generator Series Vacuum Generator VVV ■ Method to change the vacuum port direction ■Follow the below procedures for changing vacuum port direction. ① Loosen fastening bolts of both port sides, then rotate the body to change the direction of vacuum ports. ② When changing the direction, be sure to align the Double-D seams of the heads and brackets when rotating the ejector body. ③ Fix the heads and brackets by tightening the fastening bolt with the tightening torque of 2.4 to 2.66Nm. Exhaust head ( D-cut face) ●Air supply port side Exhaust port Fastening bolt Exhaust head ( D-cut face)

Open the catalog to page 9

Common Safety Instructions for Vacuum Series Before selecting or using PISCO products, read the following instructions. Read the detailed instructions for individual series. 1. There is always a risk work pieces falling off during the vacuum operation. Please be sure to take into consideration safety measures against the falling of them or possible damage(s) caused by falling components. 2. Avoid supplying more than 14.5psi (0.1MPa) pressure constantly in a vacuum circuit. Since vacuum generators are not explosive-proof, there is a risk of damaging the products. 3. Pay attention to the...

Open the catalog to page 10

8. The material of plastic filter cover for VQ and VFU series is PA. Avoid the adherence of chemicals below to the products, and do not use them under those chemical environments. ● Table Chemical Name Chemical Name Chromic acid(10% 70℃) Chromic acid(25% 70℃) Chlorosulfonic acid Chlorotoluene Chlorobenzene Chemical Name Aniline Ethylene chlorohydrin Epichlorohydrin Ethyl chloride(Chloroethane) Thionyl chloride Benzyl chloride Methyl chloride Hydrochloric acid(20% 80℃) Hydrochloric acid(37% 20℃) Nitrohydrochloric acid Ozone Sodium peroxide Caustic soda(30% 70℃) Potassium permanganate Formic...

Open the catalog to page 11All NIHON PISCO CO. catalogs and technical brochures

-

CTB series

1 Pages

-

FUS8 series

3 Pages

-

31 & 32 Series

20 Pages

-

Vacuum Pad Soft Series

86 Pages

-

VP series

106 Pages

-

CHA series

8 Pages

-

Gripper Series

15 Pages

-

SVB Series

50 Pages

-

SVA series

13 Pages

-

SVR series

31 Pages

-

NSB series

8 Pages

-

Ball Valve SUS304 series

8 Pages

-

BV series

8 Pages

-

HV series

5 Pages

-

Cable clamp & Dividing sheet

8 Pages

-

Plarailchain SC

15 Pages

-

Plarailchain SPO

12 Pages

-

Plarailchain SP

14 Pages

-

HPO

12 Pages

-

HPU

12 Pages

-

PJN series

15 Pages

-

KJNC series

15 Pages

-

SSJS series

6 Pages

-

Flow Control Valve PP Series

12 Pages

-

Stainless SUS316

13 Pages

-

UE series

12 Pages

-

FB series

1 Pages

-

CTA series

1 Pages

-

SFTN series

2 Pages

-

SET series

1 Pages

-

SFT series

14 Pages

-

ULF series

12 Pages

-

UCQ series

2 Pages

-

UQ series

12 Pages

-

NB series

12 Pages

-

NA series

12 Pages

-

UD series

12 Pages

-

UBS series

12 Pages

-

UBT series

12 Pages

-

UC series

1 Pages

-

UB series

12 Pages

-

AK/AS series

26 Pages

-

NK series

18 Pages

-

Brass Series

30 Pages

-

V-0 series

27 Pages

-

EG Series

27 Pages

-

PP Fitting series

12 Pages

-

PP Series

26 Pages

-

AP series

18 Pages

-

SL series

16 Pages

-

P-SUS series

33 Pages

-

NS series

24 Pages

-

SSP series

8 Pages

-

ATS series

6 Pages

-

Air Filter

20 Pages

-

Combination Unit Series

25 Pages

-

SFU series

9 Pages

-

JP series

15 Pages

-

ET series

11 Pages

-

EQ series

19 Pages

-

CVLU series

21 Pages

-

CV series

24 Pages

-

JN series

25 Pages

-

Speed Controller Constant Flow

15 Pages

-

JSD series

10 Pages

-

JS Low-Flow series

17 Pages

-

JSC series

13 Pages

-

JS series

30 Pages

-

Miniature Pressure Regulator

12 Pages

-

MA series

16 Pages

-

RH series

16 Pages

-

R series

16 Pages

-

PS series

16 Pages

-

L series

41 Pages

-

FUS20

7 Pages

-

Small Flow Sensor FUS8 Sries

3 Pages

-

GP series

13 Pages

-

VUS-32. SEU-32 Series

1 Pages

-

Small Pressure Sensor 11-series

24 Pages

-

VUS12 series

2 Pages

-

VUS21 series

14 Pages

-

VUS8-S series

22 Pages

-

JSD series

10 Pages

-

Orifice Fitting Series

6 Pages

-

JK series

10 Pages

-

RVFUP series

6 Pages

-

VLF series

16 Pages

-

VFL series

8 Pages

-

VF series

22 Pages

-

ECV series

8 Pages

-

VPLFC, VPLFD series

17 Pages

-

VPKE series

4 Pages

-

RPV06 Series

8 Pages

-

VZ Series

34 Pages

-

VX Series

42 Pages

-

VQ Series

4 Pages

-

VN Series

40 Pages

-

VK series

53 Pages

-

VJ Series

34 Pages

-

VG series

21 Pages

-

VRL series

17 Pages

-

VLS series

4 Pages

-

VM | VC series

28 Pages

-

VY series

24 Pages

-

VB series

11 Pages

-

VH | VS series

28 Pages

-

VPHMP series

12 Pages

-

VYR series

5 Pages

-

HS series

13 Pages

-

HML series

14 Pages

-

VRG series

18 Pages

-

Dry Unit Series

33 Pages

-

Fiber Membrane Air Dryer

12 Pages

-

VLM series

12 Pages

-

VSPE series

5 Pages

-

VT series

21 Pages

-

PB series

13 Pages

-

JSG series

17 Pages

-

pararel

3 Pages

-

fitting

4 Pages

-

BJSU series

4 Pages

-

SC

15 Pages

-

SPO

12 Pages

-

SP

13 Pages

-

RPV pump

8 Pages

-

Pre-set

6 Pages

-

Stainless Steel Ball Valve

8 Pages

-

SUS316 Flow Control Valve

6 Pages

-

Flange

13 Pages

-

HML

14 Pages

-

End of Arm Vacuum Gripper

12 Pages

-

VYR

5 Pages

-

EOAT VRG | VMG series

18 Pages

-

VPLFC

17 Pages

-

SVB

172 Pages

-

SVR

39 Pages

-

8mm Sensor

22 Pages

-

Vacuum Filter

28 Pages

-

Fall Prevention

18 Pages

-

Vacuum Pen

21 Pages

-

Push-Rod Release

4 Pages

-

cylinder

22 Pages

-

FDAbellows

6 Pages

-

Oval

80 Pages

-

sponge

50 Pages

-

mark-free

34 Pages

-

flat

42 Pages

-

Ultrathin

34 Pages

-

packaging bag

13 Pages

-

multi-bellow

46 Pages

-

bellows pad

74 Pages

-

Skid proof pad

42 Pages

-

soft bellow pad

60 Pages

-

soft pad

66 Pages

-

VRL

17 Pages

-

VH VS VC VUM VU VY VB

336 Pages

-

VZ

34 Pages

-

VX

42 Pages

-

VVV

11 Pages

-

VQ

42 Pages

-

VN

40 Pages

-

VLS

4 Pages

-

VLM

12 Pages

-

VK

53 Pages

-

VJ

34 Pages

-

VG

21 Pages

-

Vacuum Tube

12 Pages

-

Twin Coiling

12 Pages

-

Tube Cutter

12 Pages

-

Polyurethane Tube

12 Pages

-

Nylon Tube Series

12 Pages

-

Multi-core Planar Tube

12 Pages

-

Low-Friction Polyurethane Tube

12 Pages

-

Insert Ring

12 Pages

-

Fluororesin (PFA) Tube

14 Pages

-

UL series

12 Pages

-

Anti-spatter Tube

12 Pages

-

Tube Fitting PP Series

26 Pages

-

Tube Fitting Mini Series

41 Pages

-

Tube Fitting Chemical Series

18 Pages

-

K series

30 Pages

-

Stop Fitting Series

16 Pages

-

Rotary Joint Series

16 Pages

-

Multi-Circuit Rotary Block

12 Pages

-

Minimal Fitting Series

20 Pages

-

Main Block Series

24 Pages

-

Light Coupling Series

24 Pages

-

High Rotary Joint Series

16 Pages

-

Connector Series

16 Pages

-

Color Cap

12 Pages

-

Brass Compression Fitting Series

18 Pages

-

2-Circuit Junction Block Series

16 Pages

-

Vacuum EOAT Kit HML

14 Pages

-

Vacduum gripper

18 Pages

-

Mounting Flange for EOAT.pdf

13 Pages

-

SSNC series

13 Pages

-

SJSC series

24 Pages

-

Speed Controller Series

32 Pages

-

Speed Controller PP Series

17 Pages

-

Speed Controller Low Flow

17 Pages

-

Speed Controller High Flow

13 Pages

-

Speed Controller Brass Series

15 Pages

-

KJSC series

17 Pages

-

Silencer Series

13 Pages

-

Quick Exhaust Valve Series

19 Pages

-

Pressure Gauge Series

13 Pages

-

Miniture quick-exhaust

17 Pages

-

Fixed Orifice Joint Series

22 Pages

-

Check Valve

4 Pages

-

SUS304_Ball Valve Series

8 Pages

-

Parallel Gripper

6 Pages

-

JSG

17 Pages

-

GENERAL

106 Pages

-

Mechanical Valve Series

19 Pages

-

Ball Valve Series

19 Pages

-

Stainless Steel ball valve

6 Pages

-

Hand Valve Series

15 Pages

-

Change Valve

11 Pages

-

SVA21 Series

21 Pages

-

P Series

71 Pages

-

SVA20 Series

43 Pages

-

RegulatorPL031821m

12 Pages

-

BJSU series

6 Pages

-

NP68-01e

17 Pages