Website:

NIHON PISCO CO., Ltd.

Website:

NIHON PISCO CO., Ltd.

Group: 株式会社日本ピスコ

Catalog excerpts

Vacuum Generator Multi stage nozzle ejector ensuring high vacuum level of 27.8 inHg ( -94kPa). High suction flow of Max. 39.2cfm (1,110ℓ)/ min[ANR] with multi layer structure. High Flow and High Vacuum Level Vacuum Generator

Open the catalog to page 1

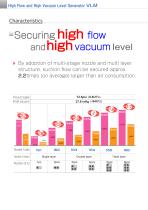

High Flow and High Vacuum Level Generator VLM Securing high flow and high vacuum level ▶ By adoption of multi-stage nozzle and multi layer structure, suction flow can be secured approx. 2.2times (on average) larger than air consumption. Pressure Supply Final vacuum About About flow About Number of layers Nozzle Q’ ty Nozzle Code

Open the catalog to page 2

Excellent in ozone resistance Silencer installing direction is selectable. ▶ Selectable from Three directions; Side, Front(*1) and With rotary joint, depending on the installation space. With rotary joint *1. Front installation is only for single layer type: 161, 162. *2. Vacuum characteristic changes by silencer Q’ty and its installing direction. Body can be fixed freely with two brackets. Bottom face fixing Side face fixing Basic Venturi Principle of multi-stage

Open the catalog to page 3

Suitable for applications in various industrial fields. ▶ Best suited for a various range of industries, as well as automobile, semiconductor, food and medicine industries. Suction Conveyance Best suited for large and heavy or porous work-piece in automobile industry and packaging industry, etc. Defoaming・Deaeration Bubble and air contained in adhesive, cosmetics (cream) and distilled water can be removed. Vacuum packing Can be used for vacuum packing of food or the like, removing air from the package. Vacuum Holding The processing accuracy can be stabilized because the distortion and...

Open the catalog to page 4

High Flow and High Vacuum Level Generator VLM Model Designation (Example) ③.Exhaust port(Connection type : Taper pipe female thread, Size : Rc3/4) Code 161, 162 163, 164 165, 166 (Single layer) (Double layer) (Triple layer) Silencer 1pc. Rotate joint 1pc. End cap 2pcs Silencer 2pcs, Rotate joint 2pcs, End cap 3pcs Silencer 3pcs, Rotate joint 3pcs, End cap 4pcs ※.All type contain 2pcs of bracket for VLM installation and plug for pressure gauge port. (Taper pipe female thread) Air supply port size ▶ 02:Rc1/4 ②.Vacuum port size Code Taper pipe female thread ①.Nozzle specification Code Layer...

Open the catalog to page 5

Specifications 161 162 Single layer 1 pc. 2 pcs Nozzle type Layers Nozzle quantity Suction flow rate (/min ANR) Air consumption (/min ANR) Fluid medium Operating pressure range Rated supply pressure Operating temp. range Nozzle diameter (mm) Parts Top case Middle case Bottom case Nozzle Ass’y Nozzle clip End cap Rotate joint Silencer Hexagon socket head bolt Case packing Bracket Plug for pressure gauge port Material Brass, PA, Aluminum PA, Aluminum PA, Aluminum PA, FKM Iron (Electroless nickel plated) PBT Aluminum,PBT PBT, PVF Iron (Electroless nickel plated) FKM Iron (Electroless nickel...

Open the catalog to page 6

High Flow and High Vacuum Level Generator VLM Characteristics Air consumption Suction flow Final vacuum Suction flow sfcm (ℓ/min ANR) ( ) VLMH 165, 166 Triple layer) ( VLMH 165, 166 Triple layer) ( (ℓ/min ANR) ( ) Flow rate VLMH 163, 164 Double layer) ( Flow rate Final vacuum -inHg (-kPa) Final vacuum Suction flow sfcm (ℓ/min ANR) ( ) VLMH 163, 164 Double layer) ( Final vacuum -inHg (-kPa) Final vacuum -inHg (-kPa) Final vacuum -inHg (-kPa) Final vacuum -inHg (-kPa) VLMH 161, 162 Single layer) ( Flow rate Final vacuum Final vacuum -inHg (-kPa) VLMH 161, 162 Single layer) (

Open the catalog to page 7

Appearance drawing Model code:VLM H161-202-3 Single layer, nozzle 1pc. Single layer, nozzle 2pcs Silencer: Side installation ⇒3:S1 Silencer with rotate joint ⇒3:S2 Silencer: Front installation ⇒3:S1 Unit:mm Air supply port : (P) Rc1/4 Sensor port Rc1/8 : Vacuum port : (V) Rc3/4 or Rc1 80.7(※3) Silencer with rotate joint Silencer: Side installation Model code Silencer: Front installation ※1) Reference dimension when silencer installed. ※2) Reference dimension when end cap installed. ※3) Reference dimension when silencer and rotate joint installed. ※4) 2 Replaced with vacuum port size code...

Open the catalog to page 8

High Flow and High Vacuum Level Generator VLM Double layer, nozzle 3pcs Double layer, nozzle 4pcs Silencer: Side installation ⇒3:S1 Silencer with rotate joint ⇒3:S2 Unit:mm Air supply port : (P) Rc1/4 Sensor port Rc1/8 : Vacuum port : (V) Rc3/4 or Rc1 80.7(※3) Silencer with rotate joint Silencer: Side installation Sensor port Rc1/8 : Model code ※1)Reference dimension when silencer installed. ※2) Reference dimension when end cap installed. ※3) Reference dimension when silencer and rotate joint installed. ※4) 2 Replaced with vacuum port size code from the model designation (example) in page...

Open the catalog to page 9

Triple layer, nozzle 5pcs Triple layer, nozzle 6pcs Silencer: Side installation ⇒3:S1 Silencer with rotate joint ⇒3:S2 Unit:mm Air supply port : (P) Rc1/4 Sensor port Rc1/8 : Vacuum port : (V) Rc3/4 or Rc1 80.7(※3) Silencer with rotate joint Silencer: Side installation Model code ※1)Reference dimension when silencer installed. ※2) Reference dimension when end cap installed. ※3) Reference dimension when silencer and rotate joint installed. ※4) 2 Replaced with vacuum port size code from the model designation (example) in page 4. ※5) The installation method of bracket in this dimensional...

Open the catalog to page 10

High Flow and High Vacuum Level Generator VLM Maintenance ■ Follow below procedures for cleaning the nozzle and the diffuser ① .Loosen all screws on the bottom of generator and remove top case and nozzle clip. ② . Remove diffuser from the generator body. ③ . Remove nozzle 3 and nozzle 1 & 2 assʼy in this order. ( Do not disassemble nozzle 1 & 2 assʼy.) ④ .Remove deposits by air blow or wiping with soft cloth from the diffuser, nozzle, packing and seal. ⑤ .Assemble the body with the nozzle 1 &2, nozzle 3 and the diffuser in reverse order of disassembling and install the nozzle clip. Fasten...

Open the catalog to page 11

Parts Bracket Rotate joint Dummy plug Model code VLM-B Model code Model code Silencer Bush (without elbow block) Model code VLM-D Related products Push-in fittings for air supply port ※ Air supply port size : Rc1/4. Push-in fittings for vacuum port ※ These push-in fittings can be used only when the vacuum port size is Rc3/4 and installing a bush listed above (PF06-04). Tubing OD: 3/8", 1/2", 5/8", 10, 12, 16 Model code PLøD-R PL3/8-02, PL1/2-02, Large digital pressure sensor (vacuum switch) VUS-32 Compound pressure type Model code PCøD-R Model code PLøD-R ■ Easily viewable LCD dual displays....

Open the catalog to page 12All NIHON PISCO CO. catalogs and technical brochures

-

CTB series

1 Pages

-

FUS8 series

3 Pages

-

31 & 32 Series

20 Pages

-

Vacuum Pad Soft Series

86 Pages

-

VP series

106 Pages

-

CHA series

8 Pages

-

Gripper Series

15 Pages

-

SVB Series

50 Pages

-

SVA series

13 Pages

-

SVR series

31 Pages

-

NSB series

8 Pages

-

Ball Valve SUS304 series

8 Pages

-

BV series

8 Pages

-

HV series

5 Pages

-

Cable clamp & Dividing sheet

8 Pages

-

Plarailchain SC

15 Pages

-

Plarailchain SPO

12 Pages

-

Plarailchain SP

14 Pages

-

HPO

12 Pages

-

HPU

12 Pages

-

PJN series

15 Pages

-

KJNC series

15 Pages

-

SSJS series

6 Pages

-

Flow Control Valve PP Series

12 Pages

-

Stainless SUS316

13 Pages

-

UE series

12 Pages

-

FB series

1 Pages

-

CTA series

1 Pages

-

SFTN series

2 Pages

-

SET series

1 Pages

-

SFT series

14 Pages

-

ULF series

12 Pages

-

UCQ series

2 Pages

-

UQ series

12 Pages

-

NB series

12 Pages

-

NA series

12 Pages

-

UD series

12 Pages

-

UBS series

12 Pages

-

UBT series

12 Pages

-

UC series

1 Pages

-

UB series

12 Pages

-

AK/AS series

26 Pages

-

NK series

18 Pages

-

Brass Series

30 Pages

-

V-0 series

27 Pages

-

EG Series

27 Pages

-

PP Fitting series

12 Pages

-

PP Series

26 Pages

-

AP series

18 Pages

-

SL series

16 Pages

-

P-SUS series

33 Pages

-

NS series

24 Pages

-

SSP series

8 Pages

-

ATS series

6 Pages

-

Air Filter

20 Pages

-

Combination Unit Series

25 Pages

-

SFU series

9 Pages

-

JP series

15 Pages

-

ET series

11 Pages

-

EQ series

19 Pages

-

CVLU series

21 Pages

-

CV series

24 Pages

-

JN series

25 Pages

-

Speed Controller Constant Flow

15 Pages

-

JSD series

10 Pages

-

JS Low-Flow series

17 Pages

-

JSC series

13 Pages

-

JS series

30 Pages

-

Miniature Pressure Regulator

12 Pages

-

MA series

16 Pages

-

RH series

16 Pages

-

R series

16 Pages

-

PS series

16 Pages

-

L series

41 Pages

-

FUS20

7 Pages

-

Small Flow Sensor FUS8 Sries

3 Pages

-

GP series

13 Pages

-

VUS-32. SEU-32 Series

1 Pages

-

Small Pressure Sensor 11-series

24 Pages

-

VUS12 series

2 Pages

-

VUS21 series

14 Pages

-

VUS8-S series

22 Pages

-

JSD series

10 Pages

-

Orifice Fitting Series

6 Pages

-

JK series

10 Pages

-

RVFUP series

6 Pages

-

VLF series

16 Pages

-

VFL series

8 Pages

-

VF series

22 Pages

-

ECV series

8 Pages

-

VPLFC, VPLFD series

17 Pages

-

VPKE series

4 Pages

-

RPV06 Series

8 Pages

-

VZ Series

34 Pages

-

VX Series

42 Pages

-

VQ Series

4 Pages

-

VN Series

40 Pages

-

VK series

53 Pages

-

VJ Series

34 Pages

-

VG series

21 Pages

-

VRL series

17 Pages

-

VVV series

11 Pages

-

VLS series

4 Pages

-

VM | VC series

28 Pages

-

VY series

24 Pages

-

VB series

11 Pages

-

VH | VS series

28 Pages

-

VPHMP series

12 Pages

-

VYR series

5 Pages

-

HS series

13 Pages

-

HML series

14 Pages

-

VRG series

18 Pages

-

Dry Unit Series

33 Pages

-

Fiber Membrane Air Dryer

12 Pages

-

VLM series

12 Pages

-

VSPE series

5 Pages

-

VT series

21 Pages

-

PB series

13 Pages

-

JSG series

17 Pages

-

pararel

3 Pages

-

fitting

4 Pages

-

BJSU series

4 Pages

-

SC

15 Pages

-

SPO

12 Pages

-

SP

13 Pages

-

RPV pump

8 Pages

-

Pre-set

6 Pages

-

Stainless Steel Ball Valve

8 Pages

-

SUS316 Flow Control Valve

6 Pages

-

Flange

13 Pages

-

HML

14 Pages

-

End of Arm Vacuum Gripper

12 Pages

-

VYR

5 Pages

-

EOAT VRG | VMG series

18 Pages

-

VPLFC

17 Pages

-

SVB

172 Pages

-

SVR

39 Pages

-

8mm Sensor

22 Pages

-

Vacuum Filter

28 Pages

-

Fall Prevention

18 Pages

-

Vacuum Pen

21 Pages

-

Push-Rod Release

4 Pages

-

cylinder

22 Pages

-

FDAbellows

6 Pages

-

Oval

80 Pages

-

sponge

50 Pages

-

mark-free

34 Pages

-

flat

42 Pages

-

Ultrathin

34 Pages

-

packaging bag

13 Pages

-

multi-bellow

46 Pages

-

bellows pad

74 Pages

-

Skid proof pad

42 Pages

-

soft bellow pad

60 Pages

-

soft pad

66 Pages

-

VRL

17 Pages

-

VH VS VC VUM VU VY VB

336 Pages

-

VZ

34 Pages

-

VX

42 Pages

-

VVV

11 Pages

-

VQ

42 Pages

-

VN

40 Pages

-

VLS

4 Pages

-

VK

53 Pages

-

VJ

34 Pages

-

VG

21 Pages

-

Vacuum Tube

12 Pages

-

Twin Coiling

12 Pages

-

Tube Cutter

12 Pages

-

Polyurethane Tube

12 Pages

-

Nylon Tube Series

12 Pages

-

Multi-core Planar Tube

12 Pages

-

Low-Friction Polyurethane Tube

12 Pages

-

Insert Ring

12 Pages

-

Fluororesin (PFA) Tube

14 Pages

-

UL series

12 Pages

-

Anti-spatter Tube

12 Pages

-

Tube Fitting PP Series

26 Pages

-

Tube Fitting Mini Series

41 Pages

-

Tube Fitting Chemical Series

18 Pages

-

K series

30 Pages

-

Stop Fitting Series

16 Pages

-

Rotary Joint Series

16 Pages

-

Multi-Circuit Rotary Block

12 Pages

-

Minimal Fitting Series

20 Pages

-

Main Block Series

24 Pages

-

Light Coupling Series

24 Pages

-

High Rotary Joint Series

16 Pages

-

Connector Series

16 Pages

-

Color Cap

12 Pages

-

Brass Compression Fitting Series

18 Pages

-

2-Circuit Junction Block Series

16 Pages

-

Vacuum EOAT Kit HML

14 Pages

-

Vacduum gripper

18 Pages

-

Mounting Flange for EOAT.pdf

13 Pages

-

SSNC series

13 Pages

-

SJSC series

24 Pages

-

Speed Controller Series

32 Pages

-

Speed Controller PP Series

17 Pages

-

Speed Controller Low Flow

17 Pages

-

Speed Controller High Flow

13 Pages

-

Speed Controller Brass Series

15 Pages

-

KJSC series

17 Pages

-

Silencer Series

13 Pages

-

Quick Exhaust Valve Series

19 Pages

-

Pressure Gauge Series

13 Pages

-

Miniture quick-exhaust

17 Pages

-

Fixed Orifice Joint Series

22 Pages

-

Check Valve

4 Pages

-

SUS304_Ball Valve Series

8 Pages

-

Parallel Gripper

6 Pages

-

JSG

17 Pages

-

GENERAL

106 Pages

-

Mechanical Valve Series

19 Pages

-

Ball Valve Series

19 Pages

-

Stainless Steel ball valve

6 Pages

-

Hand Valve Series

15 Pages

-

Change Valve

11 Pages

-

SVA21 Series

21 Pages

-

P Series

71 Pages

-

SVA20 Series

43 Pages

-

RegulatorPL031821m

12 Pages

-

BJSU series

6 Pages

-

NP68-01e

17 Pages