Website:

NIHON PISCO CO., Ltd.

Website:

NIHON PISCO CO., Ltd.

Group: 株式会社日本ピスコ

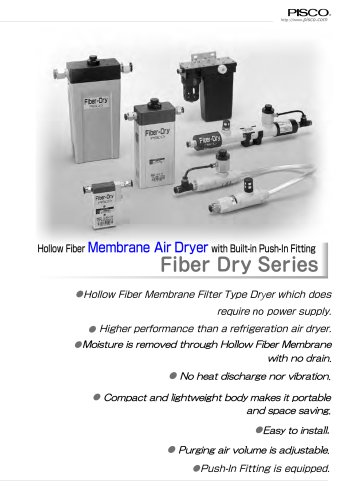

Catalog excerpts

Filter for Removing Dust and Drain in Compressed Air for Drain and Dust (Filtering Accuracy: 5µm) Bowl Guard which does not corrode. Drainage Methods: Manual or Auto Drai

Open the catalog to page 1

Air Filter ■ Model Designation (Example) FTA 02:Rc1/4(Taper Pipe Female Thread) 03:Rc3/8(Taper Pipe Female Thread) MD:Manual Drain AD:Auto Drain B:With Bracket ■ Specifications Model Code Fluid Medium Max. Operating Pressure Min. Operating Pressure Pressure Resistance Operating Temp. Range Filtering Accuracy Bowl Capacity ■ Construction Symbol of Manual Drain Adapter (Nickel-Plated Brass) O-ring (NBR) Body (Aluminum Die Casting) Deflector (POM) Buffle (POM)

Open the catalog to page 2

Bracket (Option) Manual Drain Cock Weight(g) Port Dia.:02(Rc1/4) Port Dia.:03(Rc3/8) 390 Auto Drain Cock Push-In Fitting Model Code Barb Fitting * Fill in □ on left with 02 for Rc1/4 or 03 for Rc 3/8. Fill in the end □ with R for the flow direction from right to left. Leave the end □ blank when the direction is from left to right. * Dimension in ( ) shows the dimension when the bracket is installed. ■ Characteristics Secondary Pressure (MPa) Detailed Safety Instructions Before using PISCO products, be sure to read “Safety Instructions” and “Safety Instruction Manual” and Common Safety...

Open the catalog to page 3

Filter for Removing Dust and Oil Mist in Compressed Air Mist Filter for Drain and Oil Mist (Filtering Accuracy: 0.3µm) Bowl Guard which does not corrode. Drainage Methods: Manual or Auto Drai

Open the catalog to page 4

Mist Filter ■ Model Designation (Example) FTD Mist Filter Flow Rate:300l/min(ANR) 02:Rc1/4(Taper Pipe Female Thread) 03:Rc3/8(Taper Pipe Female Thread) MD:Manual Drain AD:Auto Drain B:with Bracket ■ Specifications Model Code Fluid Medium Max. Operating Pressure Min. Operating Pressure Pressure Resistance Operating Temp. Range Filtering Accuracy Bawl Capacity ■ Construction Symbol of Manual Drain Adapter (Nickel-Plated Brass) O-ring (NBR) Body (Aluminum Die Casting) Mist Element Ass'y Symbol of Au

Open the catalog to page 5

Bracket (Option) Manual Drain Cock Weight(g) Port Dia.:02(Rc1/4) Port Dia.:03(Rc3/8) 401.5 Auto Drain Cock Push-In Fitting Model Code Barb Fitting * Fill in □ on left with 02 for Rc1/4 or 03 for Rc3/8. Fill in the end □ with R for the flow direction from right to left. Leave the end □ blank when the direction is from left to right. * Dimension in ( ) shows the dimension when the bracket is installed. ■ Characteristics Secondary Pressure (MPa) Detailed Safety Instructions Before using PISCO products, be sure to read “Safety Instructions” and “Safety Instruction Manual” and Common Safety...

Open the catalog to page 6

Filter for Removing Tiny Dust and Oil Mist in Compressed Air Micromist Filter for Tiny Dust and Oil Mist (Filtering Accuracy: 0.01µm) ● Resin-made ● Two Bowl Guard which does not corrode. Drainage Methods: Manual or Auto Drai

Open the catalog to page 7

Micromist Filter ■ Model Designation (Example) FTM Micromist Filter Flow Rate:300l/min(ANR) 02:Rc1/4(Taper Pipe Female Thread) 03:Rc3/8(Taper Pipe Female Thread) MD:Manual Drain AD:Auto Drain B:with Bracket ■ Specifications Model Code Fluid Medium Max. Operating Pressure Min. Operating Pressure Pressure Resistance Operating Temp. Range Filtering Accuracy Bawl Capacity ■ Construction Symbol of Manual Drain Adapter (Nickel-Plated Brass) O-ring (NBR) Body (Aluminum Die Casting) Micromist Element Ass'y Symbol of Au

Open the catalog to page 8

Micromist Filter Bracket (Option) Manual Drain Cock Weight(g) Port Dia.:02(Rc1/4) Port Dia.:03(Rc3/8) 401.5 Auto Drain Cock Push-In Fitting Model Code Barb Fitting * Fill in □ on left with 02 for Rc1/4 or 03 for Rc3/8. Fill in the end □ with R for the flow direction from right to left. Leave the end □ blank when the direction is from left to right. * Dimension in ( ) shows the dimension when the bracket is installed. ■ Characteristics Secondary Pressure (MPa) Detailed Safety Instructions Before using PISCO products, be sure to read “Safety Instructions” and “Safety Instruction Manual” and...

Open the catalog to page 9

Air preparation Series Safety Rules for Use 1. Installation and Piping ・Make sure to remove oils such as machining oil and carry out enough flushing before installation. ・Place the drain cock downward and vertically at the instllation of Filter, Mist Filter, Micromist Filter and Filter Regulator. 2. Atmosphere and Environment ・Avoid using or storing the product where it is exposed to sunshine, rain or water. ・Bowl material of Filter, Mist Filter, Micromist Filter and Filter Regulator is polycarbonate. Avoid using the product with the chemicals on page 255 or in the atmosphere of the...

Open the catalog to page 10

Air preparation Series 2) 0.3 and 0.01µm Element(FTD300- □ - □ D、FTM300- □ - □ D) Replacement method is different by each element. (1) For Filter Element Set “FE300DK (for 0.3µm)” or “FE300MK (for 0.01µm)” (There is a cross recessed pan head screw on the bottom of filter element) ① Detach the filter element set by untightening the cross recessed pan head screw. (When the screw guide remains of the body, go to ③ ) ② Remove the screw from the screw guide. ③ Detach the element ④ If the screw guide is detached when detaching the filter element set, place the guide on the body. ⑤ Place a new...

Open the catalog to page 11

5. Attachment / Detachment of Bowl and Filter Replacement 5-1. Attaching and Detaching Method of Bowl (Refer to the below figures) ① Detachment of Bowl Turn a bowl guard during pushing a lock button. When the lock button marking “▲” faces the body marking “▼” , the bowl is detachable. Note) Make sure that there is no internal pressure in the bowl before detaching. ② Attachment of Bowl Face the marking “▲” on the lock button and “▼” on the product body first. Push the bowl guard into the body completely and turn the guard to fix the lock button on the groove in the body. Note) Make sure that...

Open the catalog to page 12

Air preparation Series List of Chemical Resistance (Do not use the product under the following chemical atomosphere) Chemical Type Inorganic Compound Applications Metal picking solution, acid degreasing solution, skin repair solution and etc. Hydrochloric Acid, Sulfuric Acid, Nitric Acid, Fluorine, Phosphoric Acid, Chromic Acid and etc. Caustic Soda, Caustic Potash, Slaked Lime, Alkaline degreasing solution for Aqueous Ammonia, Washing Soda and other Alkali metals Materials Inorganic Salt Sodium Sulphide, Potassium Nitrate, Potassium Dichromate, Sodium Nitrate and etc. Aromatic Hydrocarbon...

Open the catalog to page 13All NIHON PISCO CO. catalogs and technical brochures

-

CTB series

1 Pages

-

FUS8 series

3 Pages

-

31 & 32 Series

20 Pages

-

Vacuum Pad Soft Series

86 Pages

-

VP series

106 Pages

-

CHA series

8 Pages

-

Gripper Series

15 Pages

-

SVB Series

50 Pages

-

SVA series

13 Pages

-

SVR series

31 Pages

-

NSB series

8 Pages

-

Ball Valve SUS304 series

8 Pages

-

BV series

8 Pages

-

HV series

5 Pages

-

Cable clamp & Dividing sheet

8 Pages

-

Plarailchain SC

15 Pages

-

Plarailchain SPO

12 Pages

-

Plarailchain SP

14 Pages

-

HPO

12 Pages

-

HPU

12 Pages

-

PJN series

15 Pages

-

KJNC series

15 Pages

-

SSJS series

6 Pages

-

Flow Control Valve PP Series

12 Pages

-

Stainless SUS316

13 Pages

-

UE series

12 Pages

-

FB series

1 Pages

-

CTA series

1 Pages

-

SFTN series

2 Pages

-

SET series

1 Pages

-

SFT series

14 Pages

-

ULF series

12 Pages

-

UCQ series

2 Pages

-

UQ series

12 Pages

-

NB series

12 Pages

-

NA series

12 Pages

-

UD series

12 Pages

-

UBS series

12 Pages

-

UBT series

12 Pages

-

UC series

1 Pages

-

UB series

12 Pages

-

AK/AS series

26 Pages

-

NK series

18 Pages

-

Brass Series

30 Pages

-

V-0 series

27 Pages

-

EG Series

27 Pages

-

PP Fitting series

12 Pages

-

PP Series

26 Pages

-

AP series

18 Pages

-

SL series

16 Pages

-

P-SUS series

33 Pages

-

NS series

24 Pages

-

SSP series

8 Pages

-

ATS series

6 Pages

-

Combination Unit Series

25 Pages

-

SFU series

9 Pages

-

JP series

15 Pages

-

ET series

11 Pages

-

EQ series

19 Pages

-

CVLU series

21 Pages

-

CV series

24 Pages

-

JN series

25 Pages

-

Speed Controller Constant Flow

15 Pages

-

JSD series

10 Pages

-

JS Low-Flow series

17 Pages

-

JSC series

13 Pages

-

JS series

30 Pages

-

Miniature Pressure Regulator

12 Pages

-

MA series

16 Pages

-

RH series

16 Pages

-

R series

16 Pages

-

PS series

16 Pages

-

L series

41 Pages

-

FUS20

7 Pages

-

Small Flow Sensor FUS8 Sries

3 Pages

-

GP series

13 Pages

-

VUS-32. SEU-32 Series

1 Pages

-

Small Pressure Sensor 11-series

24 Pages

-

VUS12 series

2 Pages

-

VUS21 series

14 Pages

-

VUS8-S series

22 Pages

-

JSD series

10 Pages

-

Orifice Fitting Series

6 Pages

-

JK series

10 Pages

-

RVFUP series

6 Pages

-

VLF series

16 Pages

-

VFL series

8 Pages

-

VF series

22 Pages

-

ECV series

8 Pages

-

VPLFC, VPLFD series

17 Pages

-

VPKE series

4 Pages

-

RPV06 Series

8 Pages

-

VZ Series

34 Pages

-

VX Series

42 Pages

-

VQ Series

4 Pages

-

VN Series

40 Pages

-

VK series

53 Pages

-

VJ Series

34 Pages

-

VG series

21 Pages

-

VRL series

17 Pages

-

VVV series

11 Pages

-

VLS series

4 Pages

-

VM | VC series

28 Pages

-

VY series

24 Pages

-

VB series

11 Pages

-

VH | VS series

28 Pages

-

VPHMP series

12 Pages

-

VYR series

5 Pages

-

HS series

13 Pages

-

HML series

14 Pages

-

VRG series

18 Pages

-

Dry Unit Series

33 Pages

-

Fiber Membrane Air Dryer

12 Pages

-

VLM series

12 Pages

-

VSPE series

5 Pages

-

VT series

21 Pages

-

PB series

13 Pages

-

JSG series

17 Pages

-

pararel

3 Pages

-

fitting

4 Pages

-

BJSU series

4 Pages

-

SC

15 Pages

-

SPO

12 Pages

-

SP

13 Pages

-

RPV pump

8 Pages

-

Pre-set

6 Pages

-

Stainless Steel Ball Valve

8 Pages

-

SUS316 Flow Control Valve

6 Pages

-

Flange

13 Pages

-

HML

14 Pages

-

End of Arm Vacuum Gripper

12 Pages

-

VYR

5 Pages

-

EOAT VRG | VMG series

18 Pages

-

VPLFC

17 Pages

-

SVB

172 Pages

-

SVR

39 Pages

-

8mm Sensor

22 Pages

-

Vacuum Filter

28 Pages

-

Fall Prevention

18 Pages

-

Vacuum Pen

21 Pages

-

Push-Rod Release

4 Pages

-

cylinder

22 Pages

-

FDAbellows

6 Pages

-

Oval

80 Pages

-

sponge

50 Pages

-

mark-free

34 Pages

-

flat

42 Pages

-

Ultrathin

34 Pages

-

packaging bag

13 Pages

-

multi-bellow

46 Pages

-

bellows pad

74 Pages

-

Skid proof pad

42 Pages

-

soft bellow pad

60 Pages

-

soft pad

66 Pages

-

VRL

17 Pages

-

VH VS VC VUM VU VY VB

336 Pages

-

VZ

34 Pages

-

VX

42 Pages

-

VVV

11 Pages

-

VQ

42 Pages

-

VN

40 Pages

-

VLS

4 Pages

-

VLM

12 Pages

-

VK

53 Pages

-

VJ

34 Pages

-

VG

21 Pages

-

Vacuum Tube

12 Pages

-

Twin Coiling

12 Pages

-

Tube Cutter

12 Pages

-

Polyurethane Tube

12 Pages

-

Nylon Tube Series

12 Pages

-

Multi-core Planar Tube

12 Pages

-

Low-Friction Polyurethane Tube

12 Pages

-

Insert Ring

12 Pages

-

Fluororesin (PFA) Tube

14 Pages

-

UL series

12 Pages

-

Anti-spatter Tube

12 Pages

-

Tube Fitting PP Series

26 Pages

-

Tube Fitting Mini Series

41 Pages

-

Tube Fitting Chemical Series

18 Pages

-

K series

30 Pages

-

Stop Fitting Series

16 Pages

-

Rotary Joint Series

16 Pages

-

Multi-Circuit Rotary Block

12 Pages

-

Minimal Fitting Series

20 Pages

-

Main Block Series

24 Pages

-

Light Coupling Series

24 Pages

-

High Rotary Joint Series

16 Pages

-

Connector Series

16 Pages

-

Color Cap

12 Pages

-

Brass Compression Fitting Series

18 Pages

-

2-Circuit Junction Block Series

16 Pages

-

Vacuum EOAT Kit HML

14 Pages

-

Vacduum gripper

18 Pages

-

Mounting Flange for EOAT.pdf

13 Pages

-

SSNC series

13 Pages

-

SJSC series

24 Pages

-

Speed Controller Series

32 Pages

-

Speed Controller PP Series

17 Pages

-

Speed Controller Low Flow

17 Pages

-

Speed Controller High Flow

13 Pages

-

Speed Controller Brass Series

15 Pages

-

KJSC series

17 Pages

-

Silencer Series

13 Pages

-

Quick Exhaust Valve Series

19 Pages

-

Pressure Gauge Series

13 Pages

-

Miniture quick-exhaust

17 Pages

-

Fixed Orifice Joint Series

22 Pages

-

Check Valve

4 Pages

-

SUS304_Ball Valve Series

8 Pages

-

Parallel Gripper

6 Pages

-

JSG

17 Pages

-

GENERAL

106 Pages

-

Mechanical Valve Series

19 Pages

-

Ball Valve Series

19 Pages

-

Stainless Steel ball valve

6 Pages

-

Hand Valve Series

15 Pages

-

Change Valve

11 Pages

-

SVA21 Series

21 Pages

-

P Series

71 Pages

-

SVA20 Series

43 Pages

-

RegulatorPL031821m

12 Pages

-

BJSU series

6 Pages

-

NP68-01e

17 Pages