Catalog excerpts

BEVELGEAR Competence and Performance

Open the catalog to page 1

BEVEL GEAR General Advantages of Spiral, Hypoid and Zerol Bevel Gears ■ High level of coverage due to the fact that several teeth are meshed simultaneously ■ Noise and oscillation damped even at high peripheral speeds ■ Resistant to elastic deformation of gears, shafts and bearings ■ Gear sets can be assembled in your preferred direction of rotation ■ Circular arc gear teeth are more resistant to bending than straight and oblique gear teeth ■ > 97% efficiency depending upon layout and lubrication ■ Very gentle transmission even at high-speed operation and under heavy load ■ Due to convex...

Open the catalog to page 2

Our Production Capabilities Milled gear tooth cutting according to Gleason Gear tooth cutting quality < 7 DIN 3965 Module Module max. outer max. tooth max. outer Shaft angle (B) ms min. ms max. edge of gear width (B) bevel 0 (A) distance from to (A) dependent on transmission ratio (B) dependent on outer bevel distance Additional gear tooth parts and dimensions are available upon request. ■ Very quiet running ■ Little heat generation ■ Flexible options to optimise noise via influencing the tooth flank geometry ■ Tooth grinding in accordance with the UMC process (Universal Motion Concept) in...

Open the catalog to page 3

BEVEL GEAR Examples of Gear Tooth Parts High-transmission hypoid gear set i=30:1 with typical shaft offset. Spiral bevel gear pair with 45° shaft angle. The smaller the bevel gear, the greater the know-how necessary.

Open the catalog to page 4

BEVEL GEAR Driven by your requirements Our engineering and special manufacturing techniques have helped us become precision manufacturer of bevel gear systems and bevel gearboxes for more than 60 years, as well as specialist in special gearboxes. Our expertise also extends to a special in-house developed workflow management system: for optimal processes between all areas involved and the customer. Our quality management system thus guarantees highest quality and cost certainty. For us, individual solutions are standard. And instead of offering expertise that‘s confined to certain areas,...

Open the catalog to page 5

■ The housing and all components must be cleaned. ■ Attention should be paid to the bearing manufacturers guidelines when assembling the rolling bearings ■ Lapped gears must be assembled in pairs. ■ The radial and axial contact surfaces should be inspected for radial and axial runout. ■ The pinion should be assembled at the correct distance. ■ The gear should be assembled with the recommen ded backlash. ■ The pinion and gear must be secured against axial thrust in both directions. ■ The tooth contact pattern should be inspected. ■ Care should be taken that the toothed gears and bearings are...

Open the catalog to page 6

BEVEL GEAR Services Gear repairs ■ Damage assessment and diagnosis ■ Repairs on clients’ premises ■ Recognition and assessment of damage ■ Communication of settings data ■ Assessment and correction of tooth contact pattern Gear inspection ■ Inspection ■ Maintenance ■ Life-span maintenance inspections on clients‘ premises Advice ■ Answers to all questions surrounding gears and their implementation ■ Information and assistance on finding gears and replacement parts Replacement parts ■ Seal kits, bearing sets, bevel gears, shafts, lubricants Tools ■ Assembly and disassembly tools GRAESSNER...

Open the catalog to page 7

■ Standard range of products and custom-made versions ■ Module ms from 0.5 to 12 ■ Diameters up to 410 mm ■ Shaft angles from 10° to 170° ■ More than 60 years of experience ■ In-house gearing calculations ■ We manufacture to your drawing or advise you of possible alternatives ■ Milled or ground gear tooth cutting ■ High torque, small size ■ For highest input speeds ■ Ratios from i = 1:1 to 5:1 ■ Torques up to 7000 Nm ■ Output via solid and hollow shaft ■ Motor mounting either directly or via coupling and lantern ■ Variable ratios and uniform dimensions Economy The cost-effective servo right...

Open the catalog to page 8All Nidec Graessner GmbH & Co. KG catalogs and technical brochures

-

KS TWINGEAR (en/de)

24 Pages

-

POWERGEAR MINIATURE (en/de)

12 Pages

-

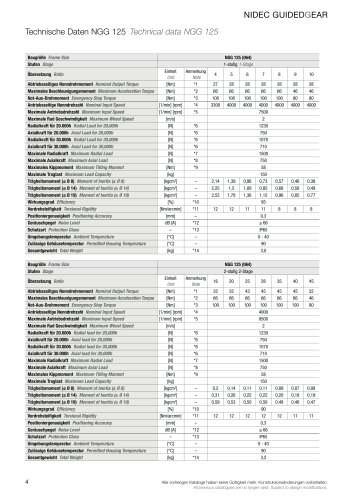

NIDEC GUIDEDGEAR (en/de)

16 Pages

-

Product overview

12 Pages

-

DYNAGEAR

12 Pages

-

PowerGear (en/de)

36 Pages

-

NGG (en/de)

9 Pages

-

DYNAGEAR ECO (en/de)

8 Pages

-

GEARFOX Software (en)

4 Pages

-

PlanetGear (en/de)

144 Pages

-

FLEXWAVE (en/de)

52 Pages

-

TorusGear

4 Pages

-

MS-GRAESSNER ENGINEERING

8 Pages

-

SmartCheck

2 Pages

-

PT1000

2 Pages