Website:

NICCOLAI TRAFILE

Website:

NICCOLAI TRAFILE

Catalog excerpts

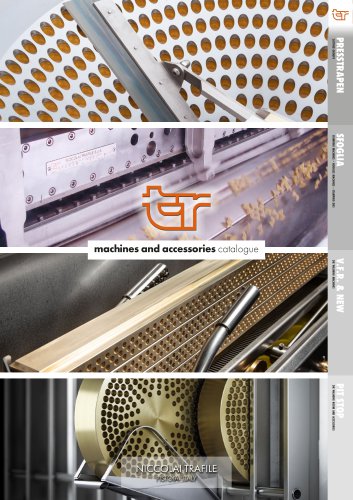

The range of the cutting groups for short goods, angle cut (penne) and straight cut macaroni launch of CARTRAPEN, the first automatic cutting unit for short goods, angle cut (penne) and straight cut macaroni and soup shape with a TURNABLE HEAD coming out of PRESSTRAPEN, the first flexible and versatile cutting group that utilizes the columns of the press as coupler and support, eliminating any type of encumbrance on the floor and in front of the shaker. Both these solutions permit to realize, with custom made layout, a functional service platform already integrated with Cartrapen, or independent in Presstrapen, to allow the operator to move easily and in total safety during the operations of changing dies, cutting cones and production control cutting groups NEW SOLUTIONS of customized fixing which allow big operating spaces when the production switches from short goods to stamped shapes in combination with one or more stamping machines: • Presstrapen GT: translating structure on linear guides. This solution, still fixed to a column, allows the transversal movement of the whole Presstrapen machine • Presstrapen DS: structure with double joint device. This solution implements the movements of standard machine adding a rotation axis to the fixing structure of the machine allowing the total rotation, thus leaving space to the operation area necessary for stamping machines Our cutting groups perfectly suit every single request, since they integrate with all types of presses, either of new plants or in revamping plants for Pasta and Snack production, and can be easily positioned with one or more stamping machine, under the same press thus avoiding to remove the machines when production switches from short goods to stamped shapes (and vice versa). PRESSTRAPEN SHORT: designed for presses with under head height below 2 meters and maintaining the same functionalities of Presstrapen PRESSTRAPEN AT: for press solutions with three or more heads, fixed under the die piston of the presses or directly on the same PRESSTRAPEN MINI: the cutting group for small pasta plants, for presses up to diam. 350 mm

Open the catalog to page 1

cutting groups A LED lighting system optimizes the vision of the cutting surface during production. The turnable head of our cutting groups allows to guarantee the reduction in operating time both for dies change and cutting cones loading (Penne production) and to work in symbiosis with one or more stamping machine, under the same press, thus reducing the time of equipment set-up avoiding to move the machines when production switches from short goods to stamped shapes (and vice versa). Integrated into the turnable head there is a knife shaft group equipped with a reduction gear powered by...

Open the catalog to page 2

Moreover, according to the production requirements and press diameter, the transparent chute is integrated by an additional stainless steel chute (double chute direct cut/penne) which directly discharges the product into the frames (drawers) of the shaker thus avoiding its leakage. Patented System: Digital videocamera, positioned inside the Presstrapen head, which transmits real time images of the shape extrusion/cut to a supervisor. The video signal can be handled by any PC on the network to be visualized by the authorized users. This solution allows the operators, thus remaining in the...

Open the catalog to page 3

cutting groups Presstrapen lifts up thanks to a pneumatic system on linear guides which guarantees the constant contact of the knife with the die without the need of any mechanic or electric locking system of its movement in working position. Control board and movements panel Knife speed (15-600 rpm) and fan speed are controlled by an inverter and can be adjusted both from the easy on board of machine keyboard with an integrated display and from PLC of the production line. Air heating with possibility of temperature regulation (45° max). Our machine can be also predisposed for external...

Open the catalog to page 4

Solution for short goods and penne production for presses up to 350 mm diameter. • Manual rotation system and uplifting movement with spiral-screw managed by wheel cutting groups Presstrapen MINI CUTTING SYSTEMS SPECIAL PENNE DIE, TRAPEN, TRAPAR, CANNELLONI CUTTER and LASAGNA CUTTER These cutting apparatuses can be mounted on each type and model of press, without altering the characteristic of the original cutting group on board of the press. The knife movement of TRAPEN, TRAPAR and SPECIAL PENNE DIE, in fact, is set directly by the cutting shaft endowed with the press, while the...

Open the catalog to page 5

cutting groups

Open the catalog to page 6

sistemi groups cuttingdi taglio CUSTOM MADE PRESSTRAPEN TYPE OVERALL DIMENSIONS PRESSTRAPEN SHORT

Open the catalog to page 7

NICCOLAI TRAFILE S.r.l. Via Cardarelli, 19 - Zona Industriale S. Agostino 51100 PISTOIA - ITALY Tel. +39 0573 92731 Fax +39 0573 934394 niccolai@niccolaitrafile.it MADE IN ITALY, SINCE 1843. Design and production LORENZO COLLORETA | WWW.LCSDESIGN.IT Photography FRANCESCA PAGLIAI | WWW.FRANCESCAPAGLIAI.COM 3D Rendering MODO E MODO STUDIO | WWW.MODOEMODOSTUDIO.COM [ed. 05-18] IMAGES AND PRODUCT SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Open the catalog to page 8All NICCOLAI TRAFILE catalogs and technical brochures

-

NICCOLAI TRAFILE

11 Pages