Catalog excerpts

1 ~ 18 ■ Table moving type 19 -32 I Column moving type Humanization design Quality control

Open the catalog to page 2

TABLE MOVING TYPE VERTICAL MACHINING CENTER H full function S common type HR box way RZ with spindle gear box D high speed direct drive Llight cutting high speed TABLE MOVING TYPE VERTICAL MACHINING CENTER Used fixed column, cross structure sliding table have high rigidity, high accuracy. After installation can be automatically complete the working procedure of drilling, boring, milling.etc. It designed for machining a variety of complex parts,such as small & middle size box. dish, plate etc. and widely used in various of industries,for example auto parts, valve, mould. IT equipment,...

Open the catalog to page 3

H/S series machines with 2 guide ways and 6 sliding blocks are designed with good supporting rigidity, no bending for worktable during the travel, stable cutting performance in all working range. A shape structural design, large rectangle section,star strengthening ribs resist

Open the catalog to page 5

SPINDLE CHARACTERISTIC P4 level bearing for spindle support, bearing large spa* high quality assembling ensure heavy duly cutting capacity. ~ yj.in.iiL iwjim iuAfid.sp.indte'with nfoh performance be!C high speed spindle, non-vibration, Jorig service llfe„'egsy fest maintenaiK heavy rtuly culling. Spindle speed |min-'|

Open the catalog to page 6

HIGH SPEED FEEDING Quenched casting + plastic box way. high rigidity and high loading capacity,suitable for heavy duty cutting.

Open the catalog to page 7

PROCESSING ABILITY max.threading diameter(mm):d materiaUow temprature steel 45#

Open the catalog to page 8

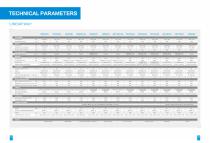

TECHNICAL PARAMETERS

Open the catalog to page 10

(gear operating) (gear operating) (gear operating) (gear operating)

Open the catalog to page 11

T SERIES WITH ROTARY TABLE VMT/F series With moving column and fixed worktable. Linear roller guideway for 3 axes with advanced structure.reliable accuracy and high efficiency. can be finished automatically with one loading.

Open the catalog to page 12

T SERIES WITH ROTARY TABLE T Series machines with hydraulic rotary worktable Proper for machining medium and small size valve body,rotary body or cubic shape parts in batches.Especially for those small parts requiring high accuracy, in large batches and frequently change. This series machines would minimize the non-cutting duration for further cost reduction.

Open the catalog to page 13

INNER COVER DESIGN The special inner cover design separates the working area and travel area. Cutting and cooling fluid are kept away from the travel area. It not only can extend the service life of the screw and linear way but also can improve the accuracy of machine tool stability. Disk 'otation is designed as cam partition structure. Willi high segmentation accuracy, low trouble rate, light sleeve to realize high rigidity and high precision suil tor high speed tool changing. ■Separate too! Claws equipped wilh high performance electronic switchmg.System are easy for and maintain.

Open the catalog to page 14

F SERIES FIXED WORK TABLE Fixed worktable with spacious working area is fit for machining long and large size workpiece. Also can be realized an high rigidity machining for irregular and inproper gravity center products. Taiwan chain type tool magazine is standard configuration Large capacity magazine, pneumatic tool change control Magazine moves along with column,quick ATC Magazine manipulator is also imported from the professional manufacturer, the indexing and tool Change of magazme

Open the catalog to page 15

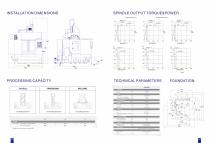

Large power and torque spindle motor. can increase cutting feed and improve the rate of material cutting SPINDLE OUTPUT POWER & TORQUE

Open the catalog to page 16

INSTALLATION DIMENSIONS T SERIES ROTARY TABLE F SERIES FIXED WORTABLE TECHNICAL PARAMETERS

Open the catalog to page 17

VM PORTAL COLUMN STRUCTURE VERTICAL MILLING CENTER VM1 207B isa medium size gantry vertical milling center. The machine with mechano-electrical unification design can be used for precision cutting and may continuously finish milling,drilling,boring.reaming and threading automatically. The machine is dedicated for processing complex workpiece of cubic, flat circular and cylindrical shapes; especially for mould The optional configuration of ZF retarder coolant through spindle and highted column can be used for valve parts processing, ■ Portal type frame structure, high rigidity, large torque,...

Open the catalog to page 18

INSTALLATION DIMENSIONS PROCESSING CAPACITY

Open the catalog to page 19

HUMANIZED DESIGN Chip conveyor is separated from water tank. The maintenance area of water tank is under of the pedal. Easy for clearing and maintenance. Electric cabinet neat and tidy all cables marked with numbers. It takes less time for maintain work and trouble solution.

Open the catalog to page 20

UALITY CONTROL The whole structure is designed with FEM finite analysis optimization. Overall rigidity and quick dynamic response can be assured. Total Deformation Type: Total Deformation Castings are made with reinforced material and resin sand process. The parts are of good stability, high rigidity and shock absorbability after second time-aging.

Open the catalog to page 21

OPTIONAL FUNCTIONS SPECIAL FIXTURES

Open the catalog to page 22All NEWAY CNC EQUIPMENT (SUZHOU) CO. catalogs and technical brochures

-

Catalogue

26 Pages

-

Summary

22 Pages

-

VALVE INDUSTRY

15 Pages

-

Gantry milling machine

22 Pages

-

Horizontal machining center

20 Pages

-

Vertical CNC lathe

15 Pages

-

Milling /Boring machine

8 Pages

-

Horizontal CNC lathe

13 Pages