Catalog excerpts

VERTICAL LATHE

Open the catalog to page 1

Vertical lathe This kind of machine especially suitable for machining large, heavy, thin deformed parts and being widely used in engineering machinery, industrial valv military industry, aerospace and oth Control system Humanization design

Open the catalog to page 2

Single-column vertical lathe Electromechanical integration design, compact structure, smaller floor space; the layout through finite element analysis and optimization, wide guideway design, high rigidity; infundibulate chip conveyor design is more smoothly ,the iron chips flow into device directly. Box way design equipped with ZF gear box, to get heavy cutting ability. The floor space of Vertical CNC lathe is less 1/2 than horizontal, improve the utilization rate of workshop; Totally enclosed protection cover keep the chips and cooling liquid within machine, to provide you a safe and clean...

Open the catalog to page 3

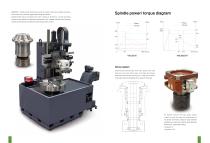

VM803H/S : spindle motor directly drive with ZF reducer with more compact structure, lower noise, more powerful, larger speed range and torque. Adopted high torque of spindle motor with a power of 18.5/22 kw, so that the strong cutting can be realized, the standard configuration of ZF retarder imported from Germany realized a wide speed of spindle and large torque heavy cutting. Spindle power/torque diagram Drive system Imported spindle bearing with high rigidity and high precision can bear radial load, axial load and torque load,which ensured the accuracy for a long time of heavy cutting...

Open the catalog to page 4

Faster tool changing, high repeated positioning accuracy All structures through the finite element analysis and strive to structure optimized to ensure the stability of the precision during machining, mechanical rigidity increases by 30% than traditional design. Column is fixed on the base, high rigidity, good and stable accuracy. Subquadrate base with high rigidity design and stable structure has a minimal impact of thermal deformation vibration. Capacious rectangular guideway design The surface of base combined with column, sliding seat, turret and all bearing blocks were scraped by...

Open the catalog to page 5

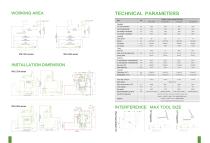

TOOL INTERFERENCE DIAGRAM WORKING AREA Passed spindle center X-axis travel X-axis travel Power cable outlet TECHNICAL PARAMETERS INSTALLATION DIMENSION VNLSOSS/H Power cable outlet

Open the catalog to page 6

This kind of machines are suitable for large, heavy, thin deformed parts processing; Vertical structure avoid the roundness error lead by workpiece gravity as horizontal clamping, and make sure the parts of roundness accuracy; workpiece gravity ensures the workpiece and fixture fit closely, to make the workpieces obtained a high positioning accuracy and machining accuracy; Mechanical and electrical integration of vertical design and compact integrated layout make it easy for installation and

Open the catalog to page 7

Spindle motor with high torque can realize heavy cutting, standard equipped with ZF retarder imported from Germany, realized the spindle wide speed range and large torque heavy cutting. ZF double speed reducer meet the low speed and heavy cutting of large diameter workpieces and smaller diameter workpieces' high speed cutting : Speed range Beam lifting system Through a worm gear drive ball screw to make beam to move up and down, be compact structure, enlarge transmission ratio and be more reliable. Beam can be moved up and down, enlarged range of processing and ensured the best rigidity of...

Open the catalog to page 8

Linear guide combined with slide guide ensures the accuracy of long term stability and heavy cutting performance. Using linear guide with oriented guideway can reduce friction force and beta ratio, to keep with a high precision when long-time processing. The plastic coated guideway has a good ant-vibration performance, large loading capacity and a smaller friction coefficient Electrical square turret High positioning accuracy, tight clamping force, large loading capacity, more stable and reliable. Inner diameter tool Integrated casting ,stable foundation With a thermal symmetric structure...

Open the catalog to page 9

WORKING AREA beam underneath passed spindle cente

Open the catalog to page 10

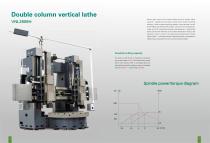

Double column vertical lathe Gantry-type column with a whole casting structure design makes products' stability be more better; Double turret, double machining efficiency, Under the same machining capacity, covers an area of a half; Used FANUC dual channel CNC system, control two turret respectively, rough and finish machining processed simultaneously; A symmetrical layout reduced the influence of the spindle temperature rising to the precision; column is fixed on the base and foundation .with a better rigidity; Beam' s movement adopts hierarchical position, guaranteed to realize heavy...

Open the catalog to page 11

Beam lifting system Beam can be moved up and down, enlarged the range of processing and ensured that process workpieces with different height of a high rigidity; Beam hierarchical move positioning completely controlled by PLC to make the operation be simple and reliable; Special assembly process ensured that the geometry precision of beams in each Main transmission structure With a symmetrical structure, effectively control the influence of thermal deformation to machine tool accuracy. Big gear is made of advanced alloy steel, after a proper heat treatment and high precision grinding...

Open the catalog to page 12

WORKING AREA beam underneath x-axis travel

Open the catalog to page 13

we have on a secondary development of some friendly man-machine interface by using of PICTURE function system. smenc IUSEETI MBimcmitiCE FtCCOftDlNG FO I HE WtSSAGt IH THE ALflFtH IH BE AH Dt'DLffiMHfi- PI L7A5E OPEJJATE COfHEjCTLV JUDGE I >P,CT I VAT E BEAT tODlffinfWSS BtRM UHtLflflP>SftflKFi rJP£H d">f|CC[KPlHfi TO THE "CTIJffl. S [ TI KIT I JIM, EFi'itr (.IP QG D9U V>|:| :ir CI ;inl ■ BEAKI (.■ UJD DEftCIrUflTE BE An [iFBLE BEAU STATUS oEflh.CLAHP* FLOOT SUIT. * BLAH UNCX * BRAKE BFEKfl BLAH SLIGHT Turret display interface (the tool location' s display of present and target, application...

Open the catalog to page 14

NEWAY INTERNATIONAL GROUP Head Office 10749 Cash Road Stafford, Texas 77477 NEWAY CNC Equipment(Suzhou) Co.,Ltd No 69 Xunyangjiang Road.Suzhou new district, RR. China 9757 Stafford Centre Drive NEWAY CNC Europe GmbH

Open the catalog to page 15All NEWAY CNC EQUIPMENT (SUZHOU) CO. catalogs and technical brochures

-

Catalogue

26 Pages

-

Summary

22 Pages

-

VALVE INDUSTRY

15 Pages

-

Gantry milling machine

22 Pages

-

Vertical machining center

22 Pages

-

Horizontal machining center

20 Pages

-

Milling /Boring machine

8 Pages

-

Horizontal CNC lathe

13 Pages