Catalog excerpts

The world’s highest capacity combine. Fact. New Holland revolutionized the way farmers harvested over 45 years ago with the introduction of groundbreaking Twin Rotor™ technology for combines. Today’s latest generation of CR Revelation combines continues the pure rotary bloodline and offers the world’s farmers world-beating grain and straw quality thanks to the gentle multi-pass action. The range topping CR10.90 is the most powerful and productive CR Revelation to date, and now has up to 700hp on tap. Innovative features such as the new award-winning IntelliSense™ combine automation system,...

Open the catalog to page 2

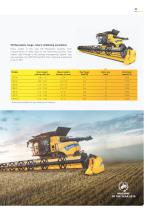

CR Revelation range: rotary combining excellence Every model in the new CR Revelation benefits from improvements in every step on the harvesting journey, from header right through to the residue management system. Just one example: the CR10.90 benefits from improved productivity of up to 10%. Models Grain header Maize headers Max Power Rotor size Grain tank cutting width (m) Number of rows [hp(CV)] (inch) capacity (l)

Open the catalog to page 3

New CR Revelation. Harvest Supremacy. MyPLM®Connect Telematics Outstanding capacity The range topping 700hp(CV) FPT Industrial Cursor 16, powering the CR10.90, delivers efficient power and when combined with advanced harvesting technology, including IntelliSteer® auto guidance, you can harvest around the clock. The remotely adjustable Dynamic Flow Control™ rotor vanes mean their position can be changed on the go in response to changing crop conditions, which can result in up to 20% higher productivity. The most advanced New Holland combine ever, now features new award-winning IntelliSense™...

Open the catalog to page 4

Up to 14,500 litre grain tank Optional new EVO NIR On-board sensor technology Twin Pitch Plus Twin Rotor™ technology with Dynamic Flow Control™ rotor vanes 700hp(CV) Cursor 16 engine with ECOBlue™ HI-eSCR 2 Stage V technology Folding unloading tube Pivoting unloading spout New chaff and Opti-Spread™ Plus system with up to 13.7m spreading width Optional four wheel drive with two speeds Opti-Clean™ system New award-winning IntelliSense™ combine automation system Opti-Fan™ technology SmartTrax™ with Flex technology or SmartTrax™ with Terraglide™ suspension available Four chain feeding system...

Open the catalog to page 5

A history of modern combining by New Holland. 1975: New Holland introduced the pioneering concept of Twin Rotor™ technology on the TR70 (145-168hp(CV)). The face of harvesting was changed forever. 1999: Six generations down the line, the higher grain handling capacity and enhanced visibility were the hallmarks of the TR89 and TR99 models. 1979: The second generation of Twin Rotors appeared in TR75, TR85 and TR95 formats, and their power was upped from 155-225hp(CV). 2002: A sleek, fresh looking seventh generation graced the world’s fields. The completely new styling, longer rotors, a larger...

Open the catalog to page 6

Built in Zedelgem The flagship CR Revelation models are built in Zedelgem, Belgium, home to New Holland’s global Centre of Harvesting Excellence. It is here, over 100 years ago, that Leon Claeys built his very first threshing machine that revolutionised the way farmers harvested. Zedelgem is synonymous with harvesting firsts, in 1952 it produced the first European self-propelled combine harvester. Today, yellow blooded engineers are committed to developing the next generation of harvesting products. The sophisticated product development process and the extensive knowledge of a dedicated...

Open the catalog to page 7

New Holland knows that the harvesting process starts with the crop. How it enters the machine will determine the quality of the harvest, therefore, a vast range of grain headers to suit every type of crop and farm have been developed and built in-house to suit your needs. Headers are available in widths ranging from 4.88 - 12.5 metres and in a wide range of configurations that can be tailored to match your requirements. The optional new front face adjust technology enables you to remotely set the position of the front face plate to ensure the header operates at the perfect angle and helps...

Open the catalog to page 8

Varifeed™ grain headers: adapt to all types of crop Flexibility for guaranteed harvesting efficiency • Varifeed™ header guarantees optimum harvesting quality and a uniform cut in fields of different crop heights • Knives can be adjusted by a full 575mm in their fore-aft position • 660 mm diameter auger with deep flights provides fast, smooth feeding • Full-width retracting fingers between each auger flight move crop down and under the auger • The Superflex header is the default choice for undulating terrain • The knife bed can flex a full 110mm in uneven fields to ensure a close cut and...

Open the catalog to page 9

Welcome to the world of the most productive draper headers. These headers are perfectly at home harvesting on the vast prairies of North America, Australia, Brazil and South Africa and deliver equally impressive performance in Europe's fields that stretch as far as the eye can see. These giants of the header world guarantee the highest throughput, right across the entire length of the cutterbar, slicing through all crops, including those which have been wide sown, such as soya beans. They are the ideal match for the CR Revelation flagship combine range. Draper headers Even feeding across...

Open the catalog to page 10

Rigid draper headers • Rigid draper headers are the ideal choice when working on large broad acre farms • The standard header height control system features four sensors mounted underneath the header table • The system works in tandem with standard gauge wheels on all models except the 9.15 metre variant to maintain a uniform cutting height • The headers can be tilted four degrees forward and three degrees rearward from the cab to manage gentle inclines or laid crops Superflex draper headers • If you want to maintain uniform cutting performance when working across the widest cutting widths...

Open the catalog to page 11

New Holland has developed an upgraded maize header line-up which has been engineered by design to perfectly match the CR Revelation's operating profile. Following extensive field testing, both the rigid and flip-up versions deliver improved harvesting productivity and reliability. The new front face adjust technology enables you to remotely set the position of the front face plate to ensure the header operates at the perfect angle.

Open the catalog to page 12All New Holland catalogs and technical brochures

-

Sustainable Efficient Technology

36 Pages

-

PLM® Connect package

12 Pages

-

HAY & FORAGE EQUIPMENT

24 Pages

-

NEW T5 AUTO COMMAND™ RANGE

20 Pages

-

WHEEL LOADERS

20 Pages

-

CX7 & CX8

44 Pages

-

CULTIVATORS

24 Pages

-

Attachments_Pocket

84 Pages

-

Ground-Engaging

32 Pages

-

Landscape

20 Pages

-

SSL - CTL

32 Pages

-

LOADER BACKHOES/TRACTOR LOADER

28 Pages

-

PROVEN SOLUTIONS FOR LANDSCAPERS

20 Pages

-

Graders F106.8 - F156.8

11 Pages

-

200 SERIES SKID STEERS LOADERS

11 Pages

-

Crawler Excavators E195C

12 Pages

-

Crawler Excavators E175C

12 Pages

-

Crawler Excavators E135B

20 Pages

-

E10 SR

2 Pages

-

WE190B PRO WE210B PRO

28 Pages

-

Crawler Excavators E140C SR

20 Pages

-

E16B, E18B

8 Pages

-

Wheel Loaders W270C - W300C

20 Pages

-

WE150B Pro

24 Pages

-

E245C

24 Pages

-

Wheel Loaders W110C - W130C

12 Pages

-

LM732

2 Pages

-

E18SR

6 Pages

-

E55BSR

2 Pages

-

LM625, LM625 Turbo

12 Pages

-

E385C, E485C

28 Pages

-

E230C SR, E260C SR

24 Pages

-

E75CSR / E85CMSR

9 Pages

-

E215LC

3 Pages

-

E265C, E305C

28 Pages

-

E215LC/E265LC

4 Pages

-

Graders F156.7A

16 Pages

-

Crawler dozers D180

12 Pages

-

Compact track loader C227

20 Pages

-

Midi Crawler Excavators > E70SR

8 Pages

-

Crawler Dozers > D150B

16 Pages

Archived catalogs

-

F106.7, F106.7A, F156.7, F156.7A

16 Pages

-

Backhoe Loaders > B90B/B90BLR

20 Pages

-

Wheeled Excavators > MH3.6 Tier 3A

12 Pages

-

Wheel Loaders > W110B/110BTC

16 Pages