Website:

NETZSCH Grinding & Dispersing

Website:

NETZSCH Grinding & Dispersing

Group: NETZSCH

Catalog excerpts

NETZSCH Fine Classifier CFS Optimal Sharpness of Cut with Highest Finenesses Business Unit GRINDING & DISPERSING

Open the catalog to page 1

Classifying of Fine Powder The NETZSCH Fine Classifier CFS is used when a screening machine cannot be used because of the desired separation limit. Optimal sharpness of cut with highest throughput rates for the separation of coarse particles, as well as fines, can be obtained in the usual operative range of approx. 30 µm to 150 μm (d99). NETZSCH Fine Classifier CFS 85

Open the catalog to page 2

Functional Description The feeding of the product to be classified is carried out via a feeding connection piece (1) or together with the classifying gas. The dispersing of the product is carried out at the lower end of the machine via the gas which streams into the classifier at high speed via a spiral housing (2) and a beater ring (3). The separation of the feed product stream into a fines stream and a coarse particle stream is carried out via a classifier wheel (4) with infinitely variable speed. The fines leave the machine via the classifier wheel through the fines outlet (5). Coarse particles...

Open the catalog to page 3

Machine and Plant Variants Materials Your Advantage is our Focus The choice of material is made to suit the requirements of the product to be processed. Mild steel as well as rust-proof stainless steel are our standards. Special materials are available upon request. Wear Protection For processing very hard and abrasive products wear-protected machine variants with e.g. Vulkollan-lining in the machine housing, a ceramic-lined fines outlet as well as a classifier wheel in ceramic- or hard-metal execution are available. Integrated classifier wheel Sharp cut classifying No oversized particles...

Open the catalog to page 4

Assembly Variants The classifier plant can be designed in various executions to especially suit the product requirements. In particular, the processing of dust-explosive hazardous products, to which group practically all organic products with a sufficient fineness belong, makes special demands. Machine- and plant executions in pressure-shock resistant design as well as for gas-tight inert gas operation are required in this case and are planned and realized reliably by our experienced engineering team taking into account your special requirements. ATEX conformity EG-TYPE INSPECTION DOCUMENT...

Open the catalog to page 5

Applications and Technical Data Coarse Particles [µm] Classifier Size Cellulose derivative (EHEC) Cellulose derivative (HPMC) Coating powder Coating powder (epoxy polyester) dedusting Cobalt oxide Maize gluten Methyl cellulose Milk powder Molybdenum powder Silver powder Tungsten carbide Wheat flour Wood flour Product Examples Activated carbon Aluminum oxide Aluminum powder Bronze powder Calcium carbonate

Open the catalog to page 6

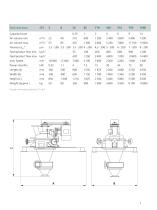

Technical Data Capacity factor Power classifier Weight (approx.) * based on limestone (density 2.7 kg/l)

Open the catalog to page 7

The NETZSCH Group is an owner-managed, international technology company with headquarters in Germany. The Business Units Analyzing & Testing, Grinding & Dispersing and Pumps & Systems represent customized solutions at the highest level. More than 3,700 employees in 36 countries and a worldwide sales and service network ensure customer proximity and competent service. Our performance standards are high. We promise our customers Proven Excellence – exceptional performance in everything we do, proven time and again since 1873. NETZSCH-Feinmahltechnik – Germany NETZSCH Trockenmahltechnik –...

Open the catalog to page 8All NETZSCH Grinding & Dispersing catalogs and technical brochures

-

NETZSCH MiniVac

2 Pages

-

NETZSCH ConduxVita

4 Pages

-

NETZSCH Pre-Grinding Mill ProPhi

12 Pages

-

NETZSCH Zumba

4 Pages

-

NETZSCH Image G&D

28 Pages

-

NETZSCH Connect

4 Pages

-

Pamir

4 Pages

-

Laboratory Mill MiniZeta

2 Pages

-

NETZSCH MasterCream

8 Pages

-

Salsa® System

12 Pages

-

NETZSCH-Beads®

20 Pages

-

NETZSCH Steam Jet Mill s-Jet®

20 Pages

-

NETZSCH Classifier Mills CSM

12 Pages

-

Milling of Spices

4 Pages

-

NETZSCH Fine Impact Mill CONDUX®

12 Pages

-

NETZSCH SPHERHO®

4 Pages

-

EpsilonVita Inline Disperser

2 Pages

-

Vacuum De-Aerator DA/DA-VS

8 Pages

-

Inline Disperser MaxShear

4 Pages

-

PMD-VC Intensive Mixers

8 Pages

-

MasterMix® Dissolver

8 Pages

-

Ψ-Mix® Inline-Disperser

12 Pages

-

Discus Intensive Grinding System

12 Pages

-

NETZSCH Mill Control Systems

12 Pages

-

Atlas Vertical Roller Mill

4 Pages

-

URAL | Air classifier mill

4 Pages

-

Bora Air Classifier

4 Pages

-

Agitator Bead Mill Alpha®

24 Pages

-

MONSOON | Whizzer Classifier

4 Pages

-

Discus Grinding System

12 Pages

-

Nanomill Zeta RS

20 Pages

-

Zeta® Grinding System

8 Pages

-

Epsilon Inline Disperser

8 Pages

-

AfterSales Support

16 Pages

-

NETZSCH CaseStudy Tango

8 Pages

-

Discus Intensive Rotor

12 Pages

-

Grinding System Neos®

12 Pages

-

Netzsch filter and cyclones

12 Pages

-

NETZSCH SmartRemoval

4 Pages

-

NETZSCH Toll Grinding

8 Pages

-

Agitator Bead Mill DeltaVita®

12 Pages

-

NETZSCH_DeltaVitaMini

4 Pages

-

ALPHA®LAB

2 Pages

-

Fine Cutting Mill SecoMy

8 Pages

-

Laboratory Plants

20 Pages

-

NETZSCH Case Study Sakata

8 Pages

-

NETZSCH Case Study S&S

8 Pages