Website:

NETZSCH Grinding & Dispersing

Website:

NETZSCH Grinding & Dispersing

Group: NETZSCH

Catalog excerpts

NETZSCH Classifier Mills CSM Fine Impact Milling Business Unit GRINDING & DISPERSING

Open the catalog to page 1

Classifier Mills for Fine Impact Milling Single stage milling is often insufficient for the production of extremely fine particle size distributions of soft to medium hard materials (up to 3 Mohs). In such cases, conventional fine impact mills are often additionally equipped with screening machines or classifiers to classify the milled product. Undesirable coarse particles are returned to the mill to be ground again. This type of separate processing requires a considerable expenditure of machinery. So-called classifier mills offer the possibility of having the same milling-classifying-effect in...

Open the catalog to page 2

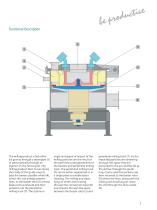

Functional Description The milling product is fed either via gravity through a downpipe (1) or pneumatically through an injector on the housing (2). The milling product then moves along the inside of the guide ring (3), past the beater classifier wheel (4), which sifts out already present fines, to the beater rotor (5) whose beaters (6) accelerate and then propel it into the peripheral milling track (7). The optimum angle and speed of impact of the milling particles are the result of the perfectly tuned geometries of the beaters and peripheral milling track. The peripheral milling track (7)...

Open the catalog to page 3

Highly Efficient and Application Oriented Your Advantage is Our Focus Highly efficient milling device with quick change beating elements and dual-use milling track, specially tuned to the needs of impact milling. Achieves a high range of particle size distributions and high throughput capacities with little rise in temperature. High precision classifier for exact limitation of the particle range in the milled product, free of oversized particles. A co-rotating immersion tube and optimum design produce the highest degrees of fineness. Large machines working with only one classifier wheel also...

Open the catalog to page 4

Optimal and low vibration operation of the classifier mill is achieved with the extremely robust design of the complete machine construction, with its welded machine housing and the coaxial construction of grinding disc and classifier wheel. Application oriented product feed either through gravity via a down pipe or pneumatically via ground level conveyance through an injector or suction air. Easy access to the milling chamber and classifier allows for simple cleaning and maintenance. When the hinged mill lid is open, the milling elements and classifier wheel are immediately accessible. The...

Open the catalog to page 5

Machine and Plant Design Our Know-How for your Requirements range from pressureless plants for the milling of inert substances to explosion proof systems. Various machines and plants for the milling of products subject to explosion can be delivered: A complete milling system is constructed in accordance with specific product requirements, taking into account your needs and our engineering expertise! Components for dependable processing such as feeding system, high-performance cyclone or ultrafine dust filter are chosen to suit your product, as well as the machine size for the desired...

Open the catalog to page 6

Adapted to Suit your Application Of course the machine designs and materials of the NETZSCH Classifier Mill CSM are application oriented: Carbon steel or Rust- and acid-resistant materials are standards Special materials are also available upon request Designs in conformity with GMP standards with extremely low surface roughness Gas-tight construction Pressure shock resistant NETZSCH Classifier Mill CSM 360 Drawing off of Difficult to Mill Particles: Often, but mainly during the milling of relatively “soft” minerals, a higher wear of milling elements occurs due to quartz content. This...

Open the catalog to page 7

Examples of Applications There are numerous application possibilities for the NETZSCH Classifier Mill CSM in many branches! Whether it is used in the chemical, plastics or paint- and varnish industry, there are many different products that can be processed and application problems that can be solved with the Classifier Mill CSM. If the fineness-specifications for the end product should change, new fineness rates can be achieved quickly and without modification of the machine by simply adjusting the classifier wheel speed! Of course, it is only possible for us to give some examples of the range of...

Open the catalog to page 8

Boron nitride Calcium citrate Cobalt metal Cobalt oxide Cocoa press cake Dried peas Iron powder Manganese(II) phosphate Nickel alloys Phenolic resin Pigments (copper) Plastic coatings Potato starch Powder coating Sodium bicarbonate Sugar beet residue Sugar substitute Tartaric acid Wheat gluten

Open the catalog to page 9

Technical Data Technical Data Power factor Grinding disc diameter Classifier wheel diameter Mill speed max. Mill drive power max. Classifier speed max. Classifier drive power max. Air volume flow max. Fineness d97 * * based on limestone (density 2.7 kg/l) NETZSCH Classifier Mill CSM 2

Open the catalog to page 10

Technical Data Weight (approx.) Quality Management Our company is certified according to DIN EN ISO 9001 in order to ensure excellent product quality and trouble-free processing of your project! Working Together to Ensure your Success! Your milling plant can be designed during the project stage in close cooperation with you, the end-user! Our skilled engineering team can advise you on the various possibilities of our classifier mill plants. www.netzsch-grinding.com Details of your local contact person and current information can be found in our website.

Open the catalog to page 11

The NETZSCH Group is an owner-managed, international technology company with headquarters in Germany. The Business Units Analyzing & Testing, Grinding & Dispersing and Pumps & Systems represent customized solutions at the highest level. More than 3,700 employees in 36 countries and a worldwide sales and service network ensure customer proximity and competent service. Our performance standards are high. We promise our customers Proven Excellence – exceptional performance in everything we do, proven time and again since 1873. NETZSCH-Feinmahltechnik – Germany NETZSCH Trockenmahltechnik –...

Open the catalog to page 12All NETZSCH Grinding & Dispersing catalogs and technical brochures

-

NETZSCH MiniVac

2 Pages

-

NETZSCH ConduxVita

4 Pages

-

NETZSCH Pre-Grinding Mill ProPhi

12 Pages

-

NETZSCH Zumba

4 Pages

-

NETZSCH Image G&D

28 Pages

-

NETZSCH Connect

4 Pages

-

Pamir

4 Pages

-

Laboratory Mill MiniZeta

2 Pages

-

NETZSCH MasterCream

8 Pages

-

Salsa® System

12 Pages

-

NETZSCH-Beads®

20 Pages

-

NETZSCH Steam Jet Mill s-Jet®

20 Pages

-

Milling of Spices

4 Pages

-

NETZSCH Fine Impact Mill CONDUX®

12 Pages

-

NETZSCH SPHERHO®

4 Pages

-

NETZSCH Fine Classifier CFS

8 Pages

-

EpsilonVita Inline Disperser

2 Pages

-

Vacuum De-Aerator DA/DA-VS

8 Pages

-

Inline Disperser MaxShear

4 Pages

-

PMD-VC Intensive Mixers

8 Pages

-

MasterMix® Dissolver

8 Pages

-

Ψ-Mix® Inline-Disperser

12 Pages

-

NETZSCH Mill Control Systems

12 Pages

-

Atlas Vertical Roller Mill

4 Pages

-

URAL | Air classifier mill

4 Pages

-

Bora Air Classifier

4 Pages

-

Agitator Bead Mill Alpha®

24 Pages

-

MONSOON | Whizzer Classifier

4 Pages

-

Discus Grinding System

12 Pages

-

Nanomill Zeta RS

20 Pages

-

Zeta® Grinding System

8 Pages

-

Epsilon Inline Disperser

8 Pages

-

AfterSales Support

16 Pages

-

NETZSCH CaseStudy Tango

8 Pages

-

Discus Intensive Rotor

12 Pages

-

Grinding System Neos®

12 Pages

-

Netzsch filter and cyclones

12 Pages

-

NETZSCH SmartRemoval

4 Pages

-

NETZSCH Toll Grinding

8 Pages

-

Agitator Bead Mill DeltaVita®

12 Pages

-

NETZSCH_DeltaVitaMini

4 Pages

-

ALPHA®LAB

2 Pages

-

Fine Cutting Mill SecoMy

8 Pages

-

Laboratory Plants

20 Pages

-

NETZSCH Case Study Sakata

8 Pages

-

NETZSCH Case Study S&S

8 Pages