Website:

NETZSCH Grinding & Dispersing

Website:

NETZSCH Grinding & Dispersing

Group: NETZSCH

Catalog excerpts

NETZSCH Fine Cutting Mill SECOMY® High-Performance Pulverization Business Unit GRINDING & DISPERSING

Open the catalog to page 1

FINE-CUTTING! NETZSCH Cutting Mills of type SECOMY® are high speed cutting mills with highfrequency cutting strokes for the ultrafine-grinding of cuttable materials. Application areas include materials that must be finely ground by means of cutting action. These include fibrous, ductile, viscoplastic or temperature-sensitive materials, as well as materials for which good flowability, high density and gentle grinding are required. The feed material is fed into the cutting chamber either by gravity or via a nip roll system. The material is cut repeatedly between the rotor- and stator knives...

Open the catalog to page 2

Focus on its Benefits for your Company ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ ∙ Lower energy costs Highest possible flexibility Best product quality High throughput capacity Low product temperatures Highest availability High bulk densities Narrow particle size distribution Possibility of blending products Simple replacement of mill Increase of productivity Small amount of space required Short waiting times Existing components can be used

Open the catalog to page 3

Drive power [kW] max. speed [min-1] Feeding width [mm] Air volume (max.) [m3h-1] Weight (approx.) [kg] Basic area [m2] The new SecoMy® machine can easily replace an existing cutting mill of the old type CS 500/1000-Z. It has identical space requirements and can increase productivity of the plant with a little additional time and effort. Compared to the previous model, performance increases of up to 100% are possible. Only the operating media must be adapted, if necessary. SecoMy® 200 with two nip-roll systems

Open the catalog to page 4

Comparison of Practical Examples 900 Wood cellulose rolled goods d97 200 µm Wood Cotton-linters cellulose rolled goods rolled goods d97 100 µm d97 150 µm Cotton-linters rolled goods d97 150 µm Wood cellulose sheet goods d97 2000 µm Constructional Characteristics Optimized variable knife design Optional pressure shock resistant execution Optional gas-tight execution Adjustable grinding air flow Can be cooled with air- and water Optimized thermal system High air throughput Outer adjustment of rotary- and fixed knives Minimum number of wear parts Extremely easy screen- and knife changing Wear...

Open the catalog to page 5

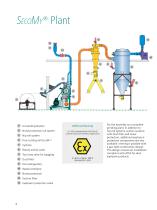

Noise protection roll system Fine-cutting mill SECOMY® Rotary airlock valve Two-way valve for bagging Dust filter Fire extinguisher Radial ventilator Noise protection Suction filter Unwinding Station Explosion protection valve ATEX conformity EC-TYPE EXAMINATION CERTIFICATE under the directive 94/9/EG, Appendix III For the assembly as a complete grinding plant, in addition to nip-roll systems, suction systems with dust filter and noiseprotection, additional explosion protection components are also available. Inerting is possible with a gas-tight construction design. This design ensures an...

Open the catalog to page 6

Feed Shape Machine Size Used paper Used paper Aramid fibers Aramid fibers Carbon fibers Wood fibers Collagen Coffee Maize straw PES film Foam material Polyamide-textiles UHWMPE PET-fibers Wheatmeal Cellulose Cellulose Cellulose Cellulose Cellulose Cellulose (wood) Cellulose (wood) Cellulose (wood) Cellulose (wood) Cellulose (wood) Cellulose (Linters) Cellulose (Linters) Cellulose (Linters) Cellulose (Linters) Cellulose-Derivate Flakes < 30 mm Flakes < 30 mm Cuttings < 30 mm Cuttings 100 x 100 mm Cut goods < 50 mm Fibrous pellets < 200 mm Beads/lumps Whole beans Stalks Layers of film Cutting...

Open the catalog to page 7

NETZSCH-Feinmahltechnik GmbH Selb, Germany NETZSCH Lohnmahltechnik GmbH Bobingen, Germany NETZSCH Premier Technologies, LLC. Exton PA, USA NETZSCH Industria e Comercio de Equipamentos de Moagem Ltda. Pomerode, Brazil NETZSCH Technologies India Private Ltd. Chennai, India NETZSCH Trockenmahltechnik GmbH Hanau, Germany NETZSCH Espana, S.A.U. Terrassa/Barcelona, Spain NETZSCH Mastermix Ltd. Lichfield, Great Britain NETZSCH (Shanghai) Machinery and Instruments Co., Ltd. Shanghai, China NETZSCH FRERES S.A.R.L. Arpajon, France NETZSCH Vakumix GmbH Weyhe-Dreye, Germany AO NETZSCH Tula Tula,...

Open the catalog to page 8All NETZSCH Grinding & Dispersing catalogs and technical brochures

-

NETZSCH MiniVac

2 Pages

-

NETZSCH ConduxVita

4 Pages

-

NETZSCH Pre-Grinding Mill ProPhi

12 Pages

-

NETZSCH Zumba

4 Pages

-

NETZSCH Image G&D

28 Pages

-

NETZSCH Connect

4 Pages

-

Pamir

4 Pages

-

Laboratory Mill MiniZeta

2 Pages

-

NETZSCH MasterCream

8 Pages

-

Salsa® System

12 Pages

-

NETZSCH-Beads®

20 Pages

-

NETZSCH Steam Jet Mill s-Jet®

20 Pages

-

NETZSCH Classifier Mills CSM

12 Pages

-

Milling of Spices

4 Pages

-

NETZSCH Fine Impact Mill CONDUX®

12 Pages

-

NETZSCH SPHERHO®

4 Pages

-

NETZSCH Fine Classifier CFS

8 Pages

-

EpsilonVita Inline Disperser

2 Pages

-

Vacuum De-Aerator DA/DA-VS

8 Pages

-

Inline Disperser MaxShear

4 Pages

-

PMD-VC Intensive Mixers

8 Pages

-

MasterMix® Dissolver

8 Pages

-

Ψ-Mix® Inline-Disperser

12 Pages

-

Discus Intensive Grinding System

12 Pages

-

NETZSCH Mill Control Systems

12 Pages

-

Atlas Vertical Roller Mill

4 Pages

-

URAL | Air classifier mill

4 Pages

-

Bora Air Classifier

4 Pages

-

Agitator Bead Mill Alpha®

24 Pages

-

MONSOON | Whizzer Classifier

4 Pages

-

Discus Grinding System

12 Pages

-

Nanomill Zeta RS

20 Pages

-

Zeta® Grinding System

8 Pages

-

Epsilon Inline Disperser

8 Pages

-

AfterSales Support

16 Pages

-

NETZSCH CaseStudy Tango

8 Pages

-

Discus Intensive Rotor

12 Pages

-

Grinding System Neos®

12 Pages

-

Netzsch filter and cyclones

12 Pages

-

NETZSCH SmartRemoval

4 Pages

-

NETZSCH Toll Grinding

8 Pages

-

Agitator Bead Mill DeltaVita®

12 Pages

-

NETZSCH_DeltaVitaMini

4 Pages

-

ALPHA®LAB

2 Pages

-

Laboratory Plants

20 Pages

-

NETZSCH Case Study Sakata

8 Pages

-

NETZSCH Case Study S&S

8 Pages