Website:

NETZSCH Analyzing & Testing

Website:

NETZSCH Analyzing & Testing

Group: NETZSCH

Catalog excerpts

NETZSCH Energy Solutions Batteries – Characterization & Process Technologies

Open the catalog to page 1

Trust NETZSCH Solutions for Battery Materials Engineers face challenges when designing lithium ion batteries. A proper thermal management strategy is required to ensure performance and the life span of the battery. The main concern with the thermal behavior of room temperature batteries is the possible significant temperature increase that may cause thermal runaway. Battery design parameters, manufacturing process and operating conditions have an effect on temperature rise/profile during battery operation. Manufacturers of battery components must deliver consistent overall quality –...

Open the catalog to page 3

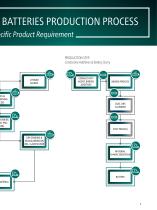

NETZSCH TECHNOLOGIES IN LI-ION We offer Tailor-Made Solutions for Every Spe PRODUCTION STEP Characterization of Components Accompanying the R&D Process PRODUCTION STEP Raw Materials for Anode & Cathode LIFE CYCLE CELL DESIGN HEAT TRE CHEMICA CESS Business Unit Analyzing & Testing DRYING Business Unit Pumps & Systems ACTIVE M Business Unit Grinding & Dispersing

Open the catalog to page 4

BATTERIES PRODUCTION PROCESS ecific Product Requirement PRODUCTION STEP Conductive Additives & Battery Slurry LITHIUM SOURCE CONDUCTIVITY AGENT, BINDER, ADDITIVES MIXING PROCESS POST PROCESS DRY GRINDING & DEAGGLOMERATION INCL. CLASSIFICATION MATERIAL CHARACTERIZATION

Open the catalog to page 5

Whether you are a battery component manufacturer looking for greater process efficiency and better quality control, or a researcher trying to determine the performance parameters of newly emerging battery materials, our solutions will offer you the new levels of insight and control needed to power the development and production of superior-quality batteries. Manufacturers of battery components must not only deliver consistent overall quality, but also throughout the entire manufacturing process. Performance and safety aspects play a significant role and influence the selection of raw...

Open the catalog to page 6

THERMAL ANALYSIS & RHEOLOGY OF BATTERIES Critical Parameters Battery Materials/ Components Cathode precursor & electrode materials Battery slurry Electrode and electrode coating Binder, additives Battery cell Material testing Crystal phase Viscosity Viscoelasticity Stability Thermal management (thermal diffusivity/ conductivity) Specific heat capacity Thermal stability Reactivity Performance changes SEI Formation Thermal stability Degradation with air/moisture Performance changes Thermal behavior Viscosity Viscoelasticity Specific heat capacity Dimensional change QA/QC Safety effectiveness...

Open the catalog to page 7

ANODE & CATHODE MATERIALS One option for the synthesis of cathode and anode materials is the so-called solid-state process. In this process route, the active material is created from the raw materials through a chemical transformation in suitable furnaces. Depending on the raw materials used, a wet grinding stage with dry pre-grinding processes can be required for the raw materials prior to the synthesis. The CGS and s-Jet® fluidized bed jet mills can be used for the dry grinding. For the wet grinding, the Zeta®, Neos or Zeta® RS agitator bead mills are used, depending on the required...

Open the catalog to page 8

APPLICATION TASKS, which we have successfully mastered DRY PROCESSING Product Working capacity Fineness [μm] [kgsolid/h] Lithium Iron Phosphate (LFP) Lithiumhydroxid (LiOH) Lithium Nickel Cobalt Mangan Oxide (NCM) Lithium Nickel Cobalt Aluminum Oxide (NCA) Lithium Cobalt Oxide (LCO) Classifier Mill Lithium Nickel Cobalt Aluminum Oxide (NCA) Classifier Mill Lithium Nickel Cobalt Mangan Oxide (NCM) Classifier Mill Lithium Nickel Cobalt Mangan Oxide (NCM) Classifier Mill Working capacity depends on required fineness and product characteristics. Working capacity [kgsolid/h] Lithium Manganese...

Open the catalog to page 9

Wet operated agitator bead mills are the most suitable technology to grind abrasive ceramic materials down to the required submicron particle size range. Different grinding systems are used depending on the required material hardness and the associated required energy density and particle size. To guarantee a total avoidance of metal contamination all machine parts with contact to the material can be made from ceramic. In order to prevent an internal short-circuit in the cells, a separator is inserted between the electrodes. The separators, which are typically made of polymer (e.g. PE, PP),...

Open the catalog to page 10

APPLICATION TASKS, which we have successfully mastered WET PROCESSING Product Working capacity [kgslurry/h] Agitator Bead Mill Agitator Bead Mill Working capacity depends on required fineness and product characteristics.

Open the catalog to page 11

CONDUCTIVE ADDITIVES & BATTERY SLURRIES For the production of high quality battery materials and components like active materials, additives, cathode or anode slurries and ceramic suspensions for inorganic composite separators a lot of different process steps and equipment are required. Conductive Additives The majority of active materials are in the electrode with limited electrical conductivity additionally the polymer matrix in the electrode needs to be electrical conductive. That is why additives are used also to reduce the required charging time of the battery when beeing added to the...

Open the catalog to page 12

Battery Slurries PMH / PML planetary mixers have established themselves as state of the art for the production of so-called battery slurries. With PMH / PML planetary mixers a combination of different processes like dissolution of binders, the premixing and the alloying of the dry components, the mixing, kneading and homogenization as well as the degassing of the high viscose pasty slurries can be realized with an excellent temperature control. However, depending on the material system used, the binder can also be dissolved first and very gently mixed after addition of the active materials....

Open the catalog to page 13

BATTERY MATERIALS Applicable Instruments, Pumps & Machines Anode & Cathode Materials Material Characterization Differential Scanning Calorimetry DSC 404 F1/F3 Pegasus® DSC 300 Caliris® Select/Supreme Simultaneous Thermal Analysis STA 509 Jupiter® series Quadrupole Mass Spectrometer QMS 505 Aëolos Thermogravimetry TG 309 Libra® Select/Supreme Thermomechanical Analysis / Dilatometry TMA 402 F1/F3 Hyperion® DIL 402 Expedis® Calorimetry Multiple Module Calorimeter MMC 274 Nexus® Accelerating Rate Calorimetry ARC® 244/305 Laser/Light Flash Analysis LFA 467 HyperFlash® Heat Flow Meter HFM 446...

Open the catalog to page 14All NETZSCH Analyzing & Testing catalogs and technical brochures

-

DMA 303 Eplexor

24 Pages

-

LFA 717 HyperFlash® Series

28 Pages

-

DSC 300 Caliris Series

28 Pages

-

STA 509 Jupiter Series

28 Pages

-

TG 309 Libra Series

24 Pages

-

DEA 288 Ionic

20 Pages

-

STA 2500 Regulus

12 Pages

-

NTA Guarded Hot Plate Series

16 Pages

-

TMA 402 F1/F3 Hyperion®

16 Pages

-

Rosand Series

20 Pages

-

Accelerating Rate Calorimetry

20 Pages

-

NTA HotBoxes

16 Pages

-

DIL 402 Expedis Select/Supreme

28 Pages

-

DIL 402 Expedis Classic

16 Pages

-

Product Overview

12 Pages

-

Advanced Materials Testing

32 Pages

-

NTA Fire Testing Systems

20 Pages

-

Kinetics NEO

20 Pages

-

TG-FTIR - product brochure

24 Pages

-

TA-QMS Coupling

28 Pages

-

Kinexus Prime DSR Series

20 Pages

-

Kinexus Prime Series

20 Pages

-

HMOR 422

1 Pages

-

RUL/CIC 421

1 Pages

-

Cone Calorimeter TCC 918

12 Pages

-

Thermal Insulation Materials

24 Pages

-

SBA 458 Nemesis®

24 Pages

-

NETZSCH NEVIO Instrument Series

24 Pages

-

LFA 427 - product brochure

24 Pages

-

DMA GABO EPLEXOR up to 1500°C

12 Pages

-

GABOMETER®

8 Pages