Website:

NETZSCH Analyzing & Testing

Website:

NETZSCH Analyzing & Testing

Group: NETZSCH

Catalog excerpts

Flooring Radiant Panel Tester – TBB 913 Reaction to Fire Tests for Floorings in Accordance with EN ISO 9239-1 (Propane Burner) and EN 13501-1 Based on ASTM E648 (Methane Burner) Analyzing & Testing

Open the catalog to page 1

Flooring Radiant Panel Tester – TBB 913 FIRE CLASSIFICATION OF FLOORING PRODUCTS – DETERMINATION OF THE BURNING BEHAVIOR USING A RADIANT HEAT SOURCE ith ance w Accord 9-1 and In 923 EN ISO 1-1 and 0 EN 135 STM E648 on A Based Measurement Results Flame propagation distance over time Smoke gas density as a function of time Critical heat radiation The flooring radiant panel testing method is used in the United States of America (ASTM E648, ASTM E970, NFPA 253) and in Europe (ISO/EN 9239). The European Union has made this type of fire test one of the requirements for the approval of floor...

Open the catalog to page 2

Temperature of the Test Chamber and Flame Area The floor covering to be tested is placed in a horizontal position under a gas-heated radiator that is inclined at 30° to the horizontal. In this position, the sample is exposed to a defined heat flow. The inclined radiant panel generates a defined heat radiation profile on the specimen ranging from a nominal maximum of 10.9 kW/m² to a minimum of 1.1 kW/m². The thermal load of the flooring in a corridor in the event of a fire is simulated. In accordance with EN 60584-1, temperature measurement occurs at the upper end plate by using a type K...

Open the catalog to page 3

Trendsetting Technology Conform to Standard Pilot Burner The small stainless steel burner inflames the specimen. The flames emerge from a total of 35 holes and ignite the specimen zero line in the ignition position during the test. After ignition of the specimen’s hot end (3 mm above the edge of the sample holder), each flame front that forms is identified and documented as a function of time and length. The critical heat flux density in [kW/m²] is the heat flux acting on the part of the sample surface, from which the flames do not spread further and may subsequently extinguish and can be...

Open the catalog to page 4

Burning Section During the test, the combustion distances are measured as a function of time, as the distance between the flame front and the sample zero line by a potentiometric position measuring system (uncertainty <1%). It is positioned via a hand wheel on the operating front of the TBB 913. The set lengths are transferred to the software and displayed. Temperature Measurement and Smoke Density The temperatures in the test chamber and exhaust channel are measured by two NiCrNi thermocouples. The white light measuring section consists of the measuring light source, measuring light...

Open the catalog to page 5

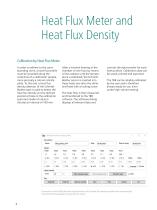

Heat Flux Meter and Heat Flux Density Calibration by Heat Flux Meter In order to adhere to the corresponding norm, a heat flux profile must be recorded along the centerline of a calibration sample, more precisely a calcium silicate plate. To this end, a heat flux density detector of the SchmidtBoelter type is used to detect the heat flux density at nine defined positions (holes in the calibration specimen made of calcium silicate) at intervals of 100 mm. After a minimal heating of the chamber of one hour by means of the radiator until the temperature is stabilized, the SchmidtBoelter sensor...

Open the catalog to page 6

Determination of the Heat Flux Density 12 Measured 10 Heat flux density /kW/m² The TBB 913 includes a watercooled heat flux density sensor of the Schmidt-Boelter type, which ISO standards officially call a heat flux meter. The well-proven heat flux measurement concept is generally referred to as the axial temperature gradient method. Its main purpose is the study of reaction to fire and fire resistance as applied, for example, in flammability tests and smoke chamber tests. For determination of the heat flux density within the sample area, the integrated heat flux meter measures the heat flux...

Open the catalog to page 7

Testing the Smoke Density Light Measuring for the Determination of the Smoke Density The light measuring system consists of a light emitter and receiver which records the light signal attenuation as a measure of smoke density over time. At the start of a test, the initial value of the receiver is set at 100% via the touch panel. If flue gas is generated during the test, the intensity of the detected light signal decreases as a function of the optical density. The TBB software displays the measurement curve. Light transmitter and receiver are covered by additional windows, which are...

Open the catalog to page 8

Euro Fire Classification For Floorings B2 Maximum security against fire E Basic security against fire FIRE CLASSIFICATION OF CONSTRUCTION PRODUCTS AND BUILDING ELEMENTS This European standard for the fire classification of construction products according to their reaction to fire tests defines the classes for the flammability of floor coverings which are now applicable throughout Europe. Further, the CE Mark for floor coverings specifies the testing or classification of flammability in accordance with EN 13501-1. Only achieved by non-flammable floor coverings which do not present any risk...

Open the catalog to page 9

TBB 913 Software and Displays The TBB software (Windows® 10) allows for the recording of all relevant measurement values. Measurement processes can be tracked and results can be displayed, saved, exported and logged in various formats. Graphical and Numerical Display of all Test Results Freely configurable display of results as chart, diagram, text or bar 16 freely configurable windows depending on display format Test results can be displayed on separate screens User Guidance for Test Procedure Graphic flow chart User instructions via dialogs Dialog for input of all parameters required by...

Open the catalog to page 10

Integrated Touch Panel for Convenient Operation Display for measured and current test values Propane: Flow rate of propane gas for radiators Air: Flow rate of compressed air for radiators Diff press: Differential pressure of the bidirectional probe Light: Transmission of the light measuring section Pyrometer: Temperature radiation pyrometer Path: Position of the path focal distance sensor Temperatures: PK – test chamber, AB – deduction, UM – environment, ZB – pilot burner, HB – heater WSM (Schmidt-Boelter type) Display heating panel: Setting the mass flow controllers for the propane and air...

Open the catalog to page 11All NETZSCH Analyzing & Testing catalogs and technical brochures

-

DMA 303 Eplexor

24 Pages

-

LFA 717 HyperFlash® Series

28 Pages

-

DSC 300 Caliris Series

28 Pages

-

STA 509 Jupiter Series

28 Pages

-

TG 309 Libra Series

24 Pages

-

DEA 288 Ionic

20 Pages

-

STA 2500 Regulus

12 Pages

-

NTA Guarded Hot Plate Series

16 Pages

-

TMA 402 F1/F3 Hyperion®

16 Pages

-

Rosand Series

20 Pages

-

Accelerating Rate Calorimetry

20 Pages

-

NTA HotBoxes

16 Pages

-

DIL 402 Expedis Select/Supreme

28 Pages

-

DIL 402 Expedis Classic

16 Pages

-

Product Overview

12 Pages

-

NETZSCH Energy Solutions

40 Pages

-

Advanced Materials Testing

32 Pages

-

NTA Fire Testing Systems

20 Pages

-

Kinetics NEO

20 Pages

-

TG-FTIR - product brochure

24 Pages

-

TA-QMS Coupling

28 Pages

-

Kinexus Prime DSR Series

20 Pages

-

Kinexus Prime Series

20 Pages

-

HMOR 422

1 Pages

-

RUL/CIC 421

1 Pages

-

Cone Calorimeter TCC 918

12 Pages

-

Thermal Insulation Materials

24 Pages

-

SBA 458 Nemesis®

24 Pages

-

NETZSCH NEVIO Instrument Series

24 Pages

-

LFA 427 - product brochure

24 Pages

-

DMA GABO EPLEXOR up to 1500°C

12 Pages

-

GABOMETER®

8 Pages