Catalog excerpts

SLIDE GUIDE SLIDE GUIDE A-1

Open the catalog to page 1

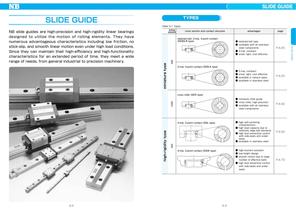

SLIDE GUIDE NB slide guides are high-precision and high-rigidity linear bearings designed to utilize the motion of rolling elements. They have numerous advantageous characteristics including low friction, no stick-slip, and smooth linear motion even under high load conditions. Since they can maintain their high-efficiency and high-functionality characteristics for an extended period of time, they meet a wide range of needs, from general industrial to precision machinery. SLIDE GUIDE cross section and contact structure retained ball, 2-row, 4-point contact (SEBS-B type) 2-row, 4-point...

Open the catalog to page 2

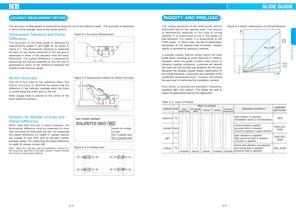

ACCURACY MEASUREMENT METHOD The accuracy of slide guides is measured by fixing the rail to the reference base. The accuracy is expressed in terms of the average value at the center portion. Dimensional Tolerance and Paired The accuracy of the slide guide is obtained by measuring the height H, and width W, as shown in Figure A-1. The dimensional tolerance is measured for each of the blocks attached to the rail and is expressed in terms of the deviation from the basic dimension. The paired difference is obtained by measuring the blocks attached to the rail and is expressed in terms of the...

Open the catalog to page 3

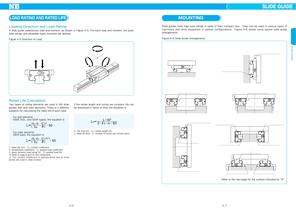

LOAD RATING AND RATED LIFE Loading Direction and Load Rating A slide guide experiences load and moment, as shown in Figure A-5. For each load and moment, the basic load ratings and allowable static moments are defined. Figure A-5 Direction of Load load rating Rated Life Calculation Two types of rolling elements are used in NB slide guides: ball and roller elements. There is a different equation for calculating the rated life of each type. If the stroke length and cycles are constant, life can be expressed in terms of time, the equation is Lh: life time (hr) &s: stroke length (m) L: rated...

Open the catalog to page 4

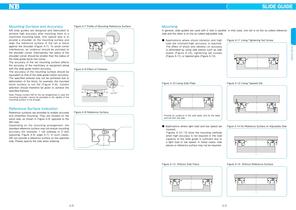

Mounting Surface and Accuracy NB slide guides are designed and fabricated to achieve high accuracy after mounting them to a machined mounting base. One typical way is to provide a shoulder on the mounting surface and align the reference surface of the rail or block against the shoulder (Figure A-7). To avoid corner interference, an undercut should be provided at the shoulder corner. Alternatively, the radius of the shoulder corner should be smaller than the radius of the slide guide block/rail corner. The accuracy of the rail mounting surface affects the accuracy of the machinery or...

Open the catalog to page 5

Mounting Procedure When reference surfaces are provided for both the table and the base, please follow the following procedure to mount the slide guide. 1. Remove burrs, scratches, dust, etc. from the base and table. Apply a low viscosity oil to the base and the table. Place the slide guide on the base carefully. Temporarily fix the rail mounting screws. 2. Tighten the screw for the side piece so that the installation reference surface and the rail reference surface are in close contact. (Figure A-16b) If a side piece is not provided, use a C clamp to position the mounting reference surface...

Open the catalog to page 6

NB Slide Guides are accurately tuned precision components. Please pay special attention to 9 Please install the Slide Guide as a set. It is not recommended to remove the block for installation. 9 When block removal is necessary, please use a temporary (plastic dummy) rail to prevent balls from 9 To put a guide block on the rail, as the pictures below show, align the reference surface and the height between the rail and a temporary rail. It is very important to maintain the original combination of block(s) Figure A-20 How to Put Guide Block on reference surface temporary rail temporary rail...

Open the catalog to page 7

DUST PREVENTION The side-seals prevent foreign particles and dust from entering the guide block in order to retain the motion accuracy, resulting in a long life time. Slide guides with side and under-seals are used in harsh environments or to prevent dust entering from Figure A-24 Side-Seal and Under-Seal Double Side-Seal Option (Series: SGL) With this option, the prevention against dust is greatly improved. Ideal for use in applications where bellows or covers are not able to be fitted over the slide guide system. Figure A-25 Double Side-Seal Scraper Option (Series: SGL) When the...

Open the catalog to page 8

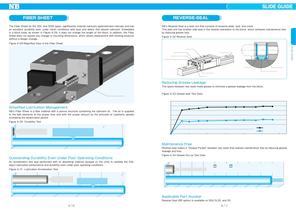

FIBER SHEET The Fiber Sheet for the SGL and SGW types, significantly extends lubricant replenishment intervals and has an excellent durability even under harsh conditions with dust and debris that absorb lubricant. Embedded in a block body, as shown in Figure A-29, it does not change the length of the block. In addition, the Fiber Sheet does not require any change in mounting dimensions, which allows replacement with existing products without a design change. Figure A-29 Magnified View of the Fiber Sheet Simplified Lubrication Management NB's Fiber Sheet is a fiber material with a porous...

Open the catalog to page 9

By protecting the entire length of the guide rail, the dust prevention is greatly enhanced. Please refer to Figure A-35 for dimensions. External dimensions and the stroke length of slide guide will change with use of bellows. Figure A-35 Dimensions of Slide Guide with Bellows guide fitting plate plate rail fitting plate cross section Note: Please do not unfasten the guide fitting plate screws. The slide guide becomes unfunctional if the guide fitting plate is removed. part number Note: 1 group indicates the minimum unit of bellows. Please specify the required stroke length. When bellows are...

Open the catalog to page 10

SLIDE GUIDE The NB slide guide SEB type is a linear motion bearing in which the ball elements roll along two raceway grooves. This is the smallest and lightest slide guide series offered by Nippon Bearing. The compact design allows for the size and weight of machinery and other equipment to be reduced. The SEB type slide guide consists of a rail with precisely machined raceway grooves and a block assembly consisting of the main body, return caps and ball elements. suitable type can be selected for any demanding operating condition. Tapped Hole Rail Type For the SEB rails, counterbore...

Open the catalog to page 11

The SEB(S) slide guides are available in two grades of accuracy: high grade and precision grade (P). Figure A-40 Motion Accuracy high grade precision grade rail length SEB(S) slide guides are available with a standard preload (blank), light preload (T1), and a positive- Table A-7 Preload Symbol and Radial Clearance unit///m Table A-8 Operating Conditions and Preload SLIDE GUIDE LOAD RATING The load rating for SEB(S) slide guides depends on Table A-9 Load Rating basic dynamic load rating basic static load rating ratained ball type non-retained ball type Figure A-41 Direction of Load vertical...

Open the catalog to page 12All NB Europe catalogs and technical brochures

-

Interchange table

28 Pages

-

FIT SERIES

2 Pages

-

Topball&Slide shaft products

28 Pages

-

Catalogue general

564 Pages

-

LINEAR SYSTEM

21 Pages

-

SLIDE ROTARY BUSH

4 Pages

-

Stainless Steel SGL Guide

2 Pages

-

SLIDE GUIDE

4 Pages

-

ACTUATOR Type BG15

2 Pages

-

ROTARY BALL SPLINE SPB type

4 Pages

-

NB REVERSE-SEAL

2 Pages

-

LEAFLET OF SHAFT DRAWINGS

9 Pages

-

SLIDE SCREW

4 Pages

-

ACTUATOR

39 Pages

-

SLIDE WAY

33 Pages

-

SHAFT

15 Pages

-

STROKE BUSH

15 Pages

-

TOPBALL

11 Pages

-

SLIDE BUSH

70 Pages

-

BALL SCREW SPLINE

4 Pages

-

BALL SPLINE

22 Pages

-

General catalog

289 Pages

-

TECHNICAL REFERENCE

4 Pages

-

TOPBALL™ Slide Products

28 Pages

-

Rotary Ball Spline SPR Type

2 Pages

-

Slide Rotary Series

14 Pages

-

Gonio Way RVF Type

8 Pages

-

STUDROLLER™ NV/NVT Type

14 Pages

-

Slide Guide SGL-HYF and HYE

8 Pages

-

Slide Bush SM G-L/SMK G-L

2 Pages

-

Shaft Leaf

9 Pages

Archived catalogs

-

Linear Systems

8 Pages