Website:

MÜLLER FRICK

Website:

MÜLLER FRICK

Group: Jakob Müller

Catalog excerpts

SMA21" + SMA800 This guarantees that yarn tension remains constant during acceleration, machine operations at production speed and braking. Due to the extremely efficient drives, should thread breakage occur, the equipment comes to an immediate stop. This prevents the broken thread end from wrapping itself around the warp beam. The braking sequence is initiated by a stop motion mounted on the creel exit, which indicates the location of the broken warp thread by means of an optical display, thus guaranteeing that the thread breakage can be corrected immediately without a long search and reducing the machine standstill to a minimum. The especially robust design of the creel permits working speeds of up to 450m-1, whereby the precise con-centricity of the powered drive shafts ensures smooth thread running. Feeding takes place in comfort from the outside of the creel, the bobbins being creeled on slewable holders, which further minimises set-up times. Universal warping machines SMA21” + SMA800 Slewable bobbin holder Thanks to the thread take-off on the inside of the machine, the respective space available can be used in optimum fashion and the gap between the creel and the warping machine considerably reduced. Space requirement for SMA800 as an example 7125 Pneumatic connection Electrical connection Copyright © 2011 by Jakob Müller AG Frick 5070 Frick Switzerland Printed in Switzerland. All rights reserved. Fascination of Ribbons and Narrow Fabrics Innovation in Machinery No part of this publication may be reproduced by any means, nor translated, nor transmitted into a machine language without the written permission of the publisher. This leaflet contains photos and technical data for information only, without contractual engagement. Jakob Müller AG Frick 5070 Frick Switzerland Tel +41 62 8655 111 Fax +41 62 8655 777 www.mueller-frick.com for the warping of elastic and non-elastic yarns on warp bobbins and bea

Open the catalog to page 1

SMA21" + SMA800 Preliminary pre-tensioner for elastic yarns The electronically adjustable preliminary pre-tensioner is used to maintain constant thread tension between the warping machine and the positive rolloff creel in every movement phase. Two different tensions are programmed: – Between the warping machine and the preliminary pre-tensioner – Between the preliminary pre-tensioner and the creel The rollers of the preliminary pre-tensioner are powered by a servomotor, which runs synchronously with the warping machine. The thread tension is maintained at a uniform level in every operating...

Open the catalog to page 2

SMA21" + SMA800 Preliminary pre-tensioner for elastic yarns The electronically adjustable preliminary pre-tensioner is used to maintain constant thread tension between the warping machine and the positive rolloff creel in every movement phase. Two different tensions are programmed: – Between the warping machine and the preliminary pre-tensioner – Between the preliminary pre-tensioner and the creel The rollers of the preliminary pre-tensioner are powered by a servomotor, which runs synchronously with the warping machine. The thread tension is maintained at a uniform level in every operating...

Open the catalog to page 3

SMA21" + SMA800 This guarantees that yarn tension remains constant during acceleration, machine operations at production speed and braking. Due to the extremely efficient drives, should thread breakage occur, the equipment comes to an immediate stop. This prevents the broken thread end from wrapping itself around the warp beam. The braking sequence is initiated by a stop motion mounted on the creel exit, which indicates the location of the broken warp thread by means of an optical display, thus guaranteeing that the thread breakage can be corrected immediately without a long search and...

Open the catalog to page 4All MÜLLER FRICK catalogs and technical brochures

-

EBRT

4 Pages

-

MDW®

4 Pages

-

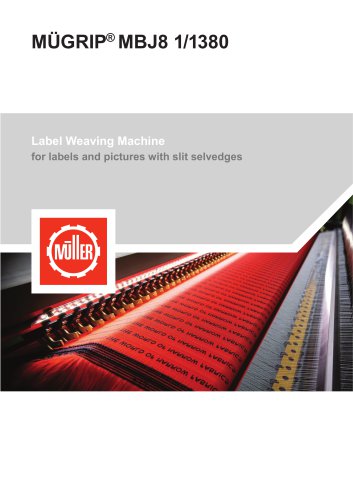

MÜGRIP® MBJ8 1/1380

4 Pages

-

NFMJ

4 Pages

-

NFM® MDW®

4 Pages

-

NFM®

4 Pages

-

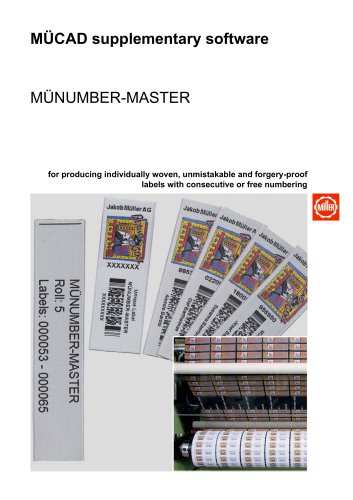

MÜNUMBER-MASTER

4 Pages

-

MÜCAD DIGICOLOR

4 Pages

-

KFF-C

2 Pages

-

BLA-S

2 Pages

-

RAM-500 /RAM-500KH

4 Pages

-

NHJM2

4 Pages

-

NG3

4 Pages

-

MuBARCODE

2 Pages

-

NF...2X...

2 Pages

-

NF

4 Pages

-

VARITEX V5J

2 Pages

-

VARITEX V5Ni

2 Pages

-

NF53... VL/LA

2 Pages

-

MÜCAD

4 Pages

-

SMA400

2 Pages

-

MW700 + MW1000

4 Pages

-

MW400

2 Pages