Website:

MÜLLER FRICK

Website:

MÜLLER FRICK

Group: Jakob Müller

Catalog excerpts

Continuous dual-end dyeing and finishing machine The Jakob Müller Group Müller researches, develops, engineers and manufactures top technology – from individual subsystems to entire system solutions, including program- ming, warping, weaving, knitting, dyeing, finishing and making-up of narrow fabrics, webbings, labels and knitted goods. Application areas – Clothing – Underwear – Sports/leisure wear – Footwear – Furniture/household textiles – Medicine – Transport – Conveyors and drives – Electronics – Building electronics – Field technology Label weaving – Complete system solutions developed specially for label production: – pattern creation – label sampling – label weaving – label cutting and folding – Systems for labels with woven or cut edges – Machines with highest speeds and minimum space requirement (needle, rapier and air technology) – Product range to satisfy all qualitative and quantitative requirements Narrow fabric weaving and make-up – Product range for producing all narrow fabrics – Complete machine range for warp patterning with dobby or jacquard shedding – All-embracing system solutions: – warping – pattern creation – narrow-fabric weaving – dyeing and finishing – photo-optics quality inspection – winding, spooling, rolling and layering narrow fabrics – Making-up narrow technical textiles Narrow-fabric warp knitting with weft insertion – Complete machine range for: – knitted goods from very simple to extremely complex designs – virtually unlimited repeat lengths – Patterning versatility and unexcelled flexibility – proven Müller compound needle – technology for runproof products – Top output capacities: – greater knitting width – top running speeds Copyright © 2004 by Jakob Müller AG Frick 5070 Frick Switzerland Printed in Switzerland. All rights reserved. Your benefits as Müller customer – Technology from one source where the emphasis has been on nothing else than narrow fabric manufacturing equipment for more than 110 years. – Collaboration with a supplier employing over 1000 people exclusively in the production of tape and narrow fabric machinery. – System solutions for your entire production – all from one source, one partner. – Machines of robust, compact design, engineered to embody the latest technological advances. – Low-maintenance systems with long life and good resale value. – Worldwide sales and service network with more than 70 bases. We are always close to you. – The Jakob Müller Institute of Narrow Fabrics is a centre for basic and advanced training, disseminating sound know-how on Müller products, as well as the design and production of textile products and industrial management. Fascination of Ribbons and Narrow Fabrics Innovation in Machinery No part of this publication may be reproduced by any means, nor translated, nor transmitted into a machine language without the written permission of the publisher. This leaflet contains photos and technical data for information only, without contractual engagement. Jakob Müller AG Frick 5070 Frick Switzerland Tel +41 62 8655 111 Fax +41 62 8655 777 www.mueller-frick.com

Open the catalog to page 1

MFR SE 1 New type of steamer The MFR SE 1 dyeing machine steamer is characterised by a surplus steam extractor. The design of the ribbon feed and removal allows the even spread of the concentrated steam through the steamer. These are ideal dyeing conditions because the ribbon is surrounded with intense Field of application – continuous dyeing and finishing of one or two ribbons – for elastic and non elastic ribbons made of polyamide (nylon), cotton, viscose, acetate, rayon or polyester – ribbon samples, small to medium-sized production quantities – ribbons of light to medium weight steam...

Open the catalog to page 2

MFR SE 1 New type of steamer The MFR SE 1 dyeing machine steamer is characterised by a surplus steam extractor. The design of the ribbon feed and removal allows the even spread of the concentrated steam through the steamer. These are ideal dyeing conditions because the ribbon is surrounded with intense Field of application – continuous dyeing and finishing of one or two ribbons – for elastic and non elastic ribbons made of polyamide (nylon), cotton, viscose, acetate, rayon or polyester – ribbon samples, small to medium-sized production quantities – ribbons of light to medium weight steam...

Open the catalog to page 3

Continuous dual-end dyeing and finishing machine The Jakob Müller Group Müller researches, develops, engineers and manufactures top technology – from individual subsystems to entire system solutions, including program- ming, warping, weaving, knitting, dyeing, finishing and making-up of narrow fabrics, webbings, labels and knitted goods. Application areas – Clothing – Underwear – Sports/leisure wear – Footwear – Furniture/household textiles – Medicine – Transport – Conveyors and drives – Electronics – Building electronics – Field technology Label weaving – Complete system solutions...

Open the catalog to page 4All MÜLLER FRICK catalogs and technical brochures

-

EBRT

4 Pages

-

MDW®

4 Pages

-

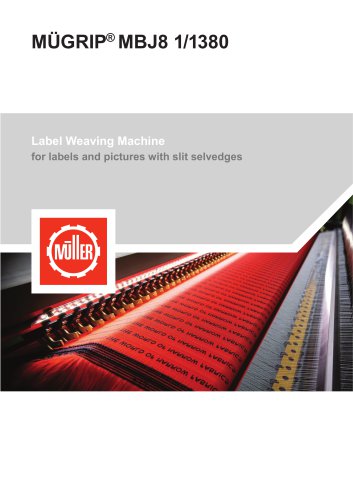

MÜGRIP® MBJ8 1/1380

4 Pages

-

NFMJ

4 Pages

-

NFM® MDW®

4 Pages

-

NFM®

4 Pages

-

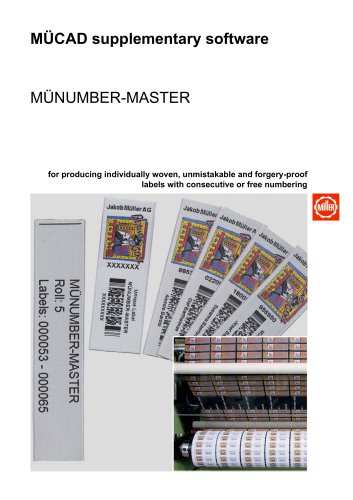

MÜNUMBER-MASTER

4 Pages

-

MÜCAD DIGICOLOR

4 Pages

-

KFF-C

2 Pages

-

BLA-S

2 Pages

-

RAM-500 /RAM-500KH

4 Pages

-

NHJM2

4 Pages

-

NG3

4 Pages

-

MuBARCODE

2 Pages

-

NF...2X...

2 Pages

-

NF

4 Pages

-

VARITEX V5J

2 Pages

-

VARITEX V5Ni

2 Pages

-

NF53... VL/LA

2 Pages

-

MÜCAD

4 Pages

-

SMA21" + SMA800

4 Pages

-

SMA400

2 Pages

-

MW700 + MW1000

4 Pages

-

MW400

2 Pages