Website:

MÜLLER FRICK

Website:

MÜLLER FRICK

Group: Jakob Müller

Catalog excerpts

MÜPRINT MDP Series Tape materials, MÜPRINT MDP process stages and consumables In general, the aforementioned advantages of the MDP inkjet system relate to polyester as a tape material. Nonetheless, these benefits also apply with limitations to other tape materials. While the employment of both sublimation and pigment inks in MDP printing Inkjet direct printing system systems results in finished products, especially in the case of acid ink use, customer will require additional process capacity for steaming, washing and drying. The table below provides an overview of the available inks, tape materials and their characteristics. Woven or knitted tapes Thermosetting for increased demands of length tolerance (MFR + MÜTHERM) Polyester, PES (min. 70% in the surface layer) Nylon, Polyamid, PA (only MÜPRINT MDP2/E) Pre-Coating (optional) MFR or KA400 inline option for improved colour with highly absorbent tapes Pre-Coating (mandatory) MFR or KA400 inline for obligatory preparation before ink jet printing with acid inks Various Cotton, Silk Design creation Adobe/Corel/photo for the printing of elastic and non-elastic tapes using the CMYK colour space MDP-RIP-Software Texprint / Variable data / Printing profile MÜPRINT MDP2 non-elastic Unwinding Sublimation inks MDP2E / MDP3E (non-elastic + elastic) Winding MDP acid inks (only MÜPRINT MDP2/E) Hotair-/ Infrared- Runout Thermosetting Pigment inks (not available for cotton and silk) Steaming: 3 – 10 min Washing: 4 – 6 basins Drying Finished product Finished product Finished product Excellent colour brilliance Maximum abrasion resistance Maximum washing fastness Good colour brilliance High abrasion resistance High washing fastness Moderate colour brilliance Low abrasion resistance Low washing fastness Customer processes Guidelines relating to consumables – All inks match the respective printer, or have been specially developed for it. The mixing or cross-use of inks from another printing system are not possible and lead to printing head blockages. – The immediately subsequent use of differing inks in a printer is not possible. However, the possibility exists for a second printer in the machine, which can be utilised on an alternating basis. Copyright © 2017 by Jakob Müller AG Frick 5070 Frick, Switzerland Printed in Switzerland. All rights reserved. – Pre-coatings for colour enhancement, or as tape preparation in case of acid inks are fully matched to the inks used. The employment of third-party makes results in major reductions in colour quality, abrasion resistance and wash fastness. – All tapes produced adjacent to one another must have similar structures and same thicknesses – CMYK colour space Fascination of Ribbons and Narrow Fabrics Innovation in Machinery No part of this publication may be reproduced by any means, nor translated, nor transmitted into a machine language without the written permission of the publisher. This leaflet contains photos and technical data for information only, without contractual engagement.

Open the catalog to page 1

Concept The MÜPRINT MDP digital printing systems are designed for the contactless, direct printing of textile tapes. As early as 2011, Jakob Müller introduced the MÜPRINT MDP2, the world's first system for the direct printing of tapes using sublimation inks. The MÜPRINT MDP2 was able to carry out the contactless, direct printing of up to 16 polyester tapes with a total width of 400 mm and, using an integrated thermofixing process, manufacture a product suitable for immediate sale, fulfilling demands in abrasion resistance and colour fastness, as well as textile standards (OEKO-TEX® )....

Open the catalog to page 2

Concept The MÜPRINT MDP digital printing systems are designed for the contactless, direct printing of textile tapes. As early as 2011, Jakob Müller introduced the MÜPRINT MDP2, the world's first system for the direct printing of tapes using sublimation inks. The MÜPRINT MDP2 was able to carry out the contactless, direct printing of up to 16 polyester tapes with a total width of 400 mm and, using an integrated thermofixing process, manufacture a product suitable for immediate sale, fulfilling demands in abrasion resistance and colour fastness, as well as textile standards (OEKO-TEX® )....

Open the catalog to page 3

MÜPRINT MDP Series Tape materials, MÜPRINT MDP process stages and consumables In general, the aforementioned advantages of the MDP inkjet system relate to polyester as a tape material. Nonetheless, these benefits also apply with limitations to other tape materials. While the employment of both sublimation and pigment inks in MDP printing Inkjet direct printing system systems results in finished products, especially in the case of acid ink use, customer will require additional process capacity for steaming, washing and drying. The table below provides an overview of the available inks, tape...

Open the catalog to page 4All MÜLLER FRICK catalogs and technical brochures

-

EBRT

4 Pages

-

MDW®

4 Pages

-

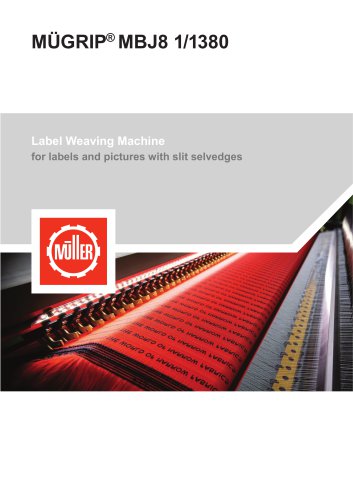

MÜGRIP® MBJ8 1/1380

4 Pages

-

NFMJ

4 Pages

-

NFM® MDW®

4 Pages

-

NFM®

4 Pages

-

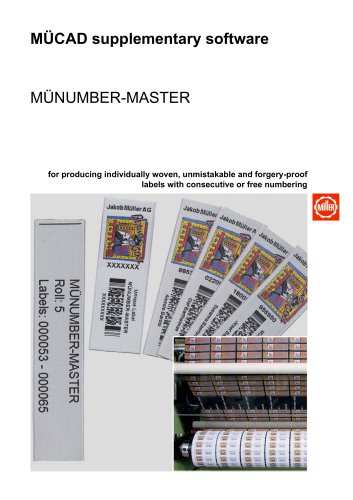

MÜNUMBER-MASTER

4 Pages

-

MÜCAD DIGICOLOR

4 Pages

-

KFF-C

2 Pages

-

BLA-S

2 Pages

-

RAM-500 /RAM-500KH

4 Pages

-

NHJM2

4 Pages

-

NG3

4 Pages

-

MuBARCODE

2 Pages

-

NF...2X...

2 Pages

-

NF

4 Pages

-

VARITEX V5J

2 Pages

-

VARITEX V5Ni

2 Pages

-

NF53... VL/LA

2 Pages

-

MÜCAD

4 Pages

-

SMA21" + SMA800

4 Pages

-

SMA400

2 Pages

-

MW700 + MW1000

4 Pages

-

MW400

2 Pages