Website:

mta robotics AG

Website:

mta robotics AG

Group: mta robotics AG

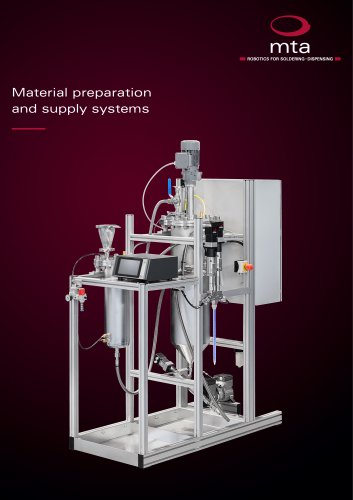

Catalog excerpts

SOLDERING & DISPENSING Selective soldering solutions

Open the catalog to page 1

From concept to turnkey solutions Unitechnologies SA, with its mta® brand, is the leader in selective soldering processes based on standardized platforms. The product range includes components, standalone systems, semi-automatic table-top robots and entirely automatic production cells or lines. Thanks to a complete infrastructure, trials can be carried out on samples using all proven mta® soldering techniques in the company’s test laboratories. Once the mta® technique has been validated, a detailed quotation is established with the proposed standard machine adapted to the customer’s...

Open the catalog to page 2

Examples of applications Soldering techniques o SOLDERING & DISPENSING With the point to point selective soldering technique, very specific points to be soldered can be selected. Compared to soldering on defined areas, this enables a higher accuracy and the possibility of adapting the soldering parameters to the requirements of each individual point. As alternative to manual soldering, the point to point soldering automated solutions guarantee a high soldering quality as they are much more repeatable and reliable than working with soldering operators. The ability of the components to be...

Open the catalog to page 3

SOLDERING & DISPENSING Induction - Large heating capacity - Dimension and geometry of the spire according to the application - Entirely transistorized system - Suitable for brazing (hard alloy) - The non-conductive parts of the components to be soldered are not heated by the induction - Contact-less soldering Technical specifications Induction head coil power max. 32kVar or 45kVar Induction head coil diameter min. 4 mm and max. 12 mm Induction head dimensions 123 x 95 x 62.5 mm Induction head weight ~2 kg Generator power supply 230V/50-60Hz Chiller pressure: min. 3.5 bar- supply:...

Open the catalog to page 4

Soldering standard platforms o MRC500 laser robotic cell The PC controlled MRC500 standard robotic cell can be used for semi or fully automatic operations of selective point to point soldering from above. The MRC500 can be equipped with the established mta® soldering techniques such as iron soldering, induction and microflame described on the previous pages. The 3 or 4 axes of the MRC500 are fully programmable through the mta® MotionEditor software including soldering parameters such as: - Solder quantity, wire feed speed, preheating/postheating times, automatic tip cleaning cycle intervals...

Open the catalog to page 5

Soldering standard platforms TR300 table-top robot OEM robot for integrator o SOLDERING & DISPENSING The PC controlled TR300 standard table-top robot can be used for semi-automatic operations of selective point to point soldering from above. The increasing requirements for processes in terms of quality, precision and repeatability lead to a similar increase in the necessary level of automation. However, when production batches are small or products widely dissimilar, the cost of sophisticated equipment can place automation beyond the reach of many would-be users. The TR300 combines the...

Open the catalog to page 6

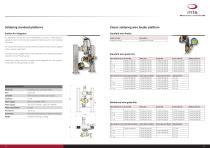

Classic soldering wire feeder platform Station for integrator Standard wire feeder o SOLDERING & DISPENSING For applications that do not require the flexibility of a robot, a simple station is available for semi or fully automatic operations of selective point to point soldering from above. The modularity of slides and standard elements enable to find a solution adapted to the customer's application. The station can be equipped with all the established mta® soldering techniques, except for the mta® PowerLas laser. Thanks to its modular concept, the station can be integrated into a line or...

Open the catalog to page 7

SOLDERING & DISPENSING MRC500 laser robotic cell Soldering platforms TR300 table-top robot Classic soldering iron Configurations - Soldering iron 80W or 150W - With or without 19'' rack - With or without wire feeder Options - Fix or mobile iron cleaning device - Automatic sponge humidifier - Set up for easy, normal and difficult products Configurations - 80W or 150W soldering iron - 1 or 2 soldering heads - 3 or 4 axes - Work area: 500x500 or 300x300mm Options - Integration of a transfer system - SMEMA interface and conveyor - LED illumination set Configurations - 80W or 150W soldering...

Open the catalog to page 8

SOLDERING & DISPENSING mta® software Platform controllers Robotic cell and table-top robot The mta® standard platforms, such as the MRC500 robotic cell and the TR300 table-top robot, are controlled using an industrial PC, running a WINDOWS operating system. The PC and all the hardware needed to control the robot and the processes are integrated and delivered within the standard platforms. State-of-the-art connection and interfaces are already integrated in order to communicate with other systems, controllers, etc. With more than 20 years of experience in the design/creation of software...

Open the catalog to page 9

Providing turnkey solutions With over 50 years of experience in automation, Unitechnologies can propose the best possible solution available for the realization of turnkey systems for all automation processes peripheral to the soldering and dispensing operations. The highly qualified staff, state-of-the-art infrastructure and proven methods of managing knowledge and mastering risks are key factors to innovative solutions perfectly adapted to the customer’s needs. Unitechnologies’ workforce faces daily challenges in mastering multidisciplinary projects. The open minded corporate culture...

Open the catalog to page 10

Solder consumables In order to guarantee a long machine life span and to avoid difficulties in acquiring spare parts, a large selection of mta® consumables and spare parts is available from the Unitechnologies’ customer service team. The consumables are limited to four main types: iron soldering tips, heating units, wire feeder guides and cleaning sponges. Each type is described below: Solder tips List of 80W solder tips Article number Cleaning sponges mta® brand has a proprietary design for the tip cleaning units which consist of two rotating sponges with manual or automatic wetting...

Open the catalog to page 11