Catalog excerpts

Adapting to the Needs of Tomorrow Founded to solve the world’s most complex engineering problems, Marc is the industry standard for solving multiphysics problems in many branches of engineering. No matter the project, you can depend on Marc’s robust nonlinear capabilities to give you the answers you need. Since inception, Marc has evolved to address new engineering challenges and continues to do so for the next age of engineering simulation. LEARN MORE www.mscsoftware.com/marc 2 | Engineering Reality Magazi

Open the catalog to page 2

Make it Smarter with CAE Simulation By Paolo Guglielmini, CEO, MSC Software Greetings Readers! elcome to this packed edition of Engineering Reality magazine. A lot has happened at MSC and Hexagon in the last 6 months. We have welcomed FTI into our organization from Canada with their world-leading metal FormingSuite simulation and costing software that their customers see huge ROI savings when they use it. We have also released our unique and innovative MSC CoSim product in February 2019, and Hexagon has accelerated its Smart Factory and Smart Autonomous Mobility initiatives where I believe...

Open the catalog to page 3

Brian Shepherd: Hexagon Smart Factory Update: ‘Make It Smarter’ Simulating Vehicle Extreme Load Cases with Adams-Marc Co-Simulation Generation and Validation of Sensor Models for Automated Driving Systems Using VIRES VTD Leveraging Adams and Luciad to Assess Mobility Characteristics of a Military Ground Vehicle Doug Neill and Keith Hanna: Space CAE – The First and Final Frontier … 4 | Engineering Reality Magazine Simufact Additive: Collaborative Simultaneous Engineering Tool for Additive Manufacturing Team D.I.A.N.A: Multibody Simulations of a Martian Rover Airbus Defence and Space: Actran...

Open the catalog to page 4

Korea Advanced Institute of Science and Technology: Simulating the Flight of the Hawkmoth Manduca Sexta Bhoomi Gadhia: Medical Innovation One Step Further through MSC Nastran and MARC Simulation 10x Productivity Gain with MSC Apex – MSC Nastran Workflow China Railway Design Corporation: Sound Attenuation Prediction of High Speed Railway Sound Barrier with Actran Liaoning Technical University: Optimizing the Drum Design of a Coal Shearer with Adams-EDEM Integrated Simulation Approach Optimize the Product Part, Not Just the Geometry - A Real World End2End Additive Manufacturing Solution...

Open the catalog to page 5

Hexagon Smart Factory Update: ‘Make It Smarter’ By Brian Shepherd, Senior Vice President Software Solutions, Hexagon’s Manufacturing Intelligence division n a previous article in this publication (Ref. 1), I outlined Hexagon’s Smart Factory strategy. For the first time in history it’s now possible for factories to harness the full potential of their manufacturing and simulation data. If we look backwards to what was called ‘Industry 3.0’, factories in the 20th century were focused on simple automation of tasks. The term ‘Smart Factory’ is just another way of saying that companies who want...

Open the catalog to page 6

want to give our customers the ability to make their products smarter today. In April 2019 we announced the release of a first solution from our SFx solution portfolio at Hannover Messe in Germany. The release of HxGN SFx | Asset Management, introduces a new IoT business model. Asset Management is a cloud-based solution that will maximize the value of our customers’ assets through Remote Monitoring, Analytics for Resource Management and, in 2020, adding Pro-active, Predictive and Prescriptive maintenance. At present, Asset Management targets the sCMM market (latest controllers only), but...

Open the catalog to page 7

Figure 3: Artist’s Impression of the Hexagon Smart Factory facility being built in Hongdao, China Figure 2: Hexagon‘s unique Additive Manufacturing solution suite and application workflows and quality are a few of the challenges that Hexagon can deliver competitive solutions to solve, namely the ability to optimize the designs of parts for specific AM processes, simulate, predict and influence the behaviors of the parts during the 3D printing process and then dimensionally validate the resulting parts. Engineering a success story with Additive Manufacturing means understanding dependencies...

Open the catalog to page 8

THE MOST WIDELY USED SIMULATION PROCESS AND DATA MANAGEMENT SOFTWARE SimManager is the world’s most widely used Simulation Process And Data Management (SPDM) software. SimManager helps organizations achieve data traceability and increase simulation throughput without increasing the number of analysts. Request a Quote! Volume IX - Summer 2019 | mscsoftware.com | 9

Open the catalog to page 9

Simulating Vehicle Extreme Load Cases with Adams-Marc Co-Simulation By Christian Kopp, Senior Technical Consultant Harald Krings, Senior Technical Specialist Yijun Fan, Global Automotive Application Manager, MSC Software 10 | Engineering Reality Magazine

Open the catalog to page 10

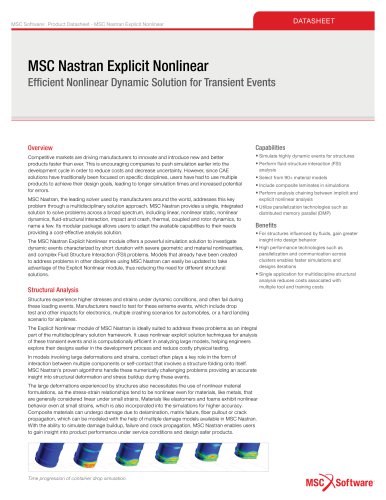

fficiently designing and testing mechanical systems for automobiles is a challenge for some engineers due to lack of a smooth integration between, for example, system dynamics and finite element analysis (FEA) software domains. An MSC Adams-Marc co-simulation product toolchain enables engineers to perform multiphysics simulations between Marc nonlinear FE technology and the Adams Multibody Dynamics (MBD) code. By so doing, multibody dynamics engineers can increase model accuracy by including non-linear structural behavior; and Finite Element Analysis (FEA) engineers can study components...

Open the catalog to page 11

challenge with a traditional MBD approach is that plastic deformation of the underbody can’t be captured during a full vehicle analysis, and if the engineers try to simulate the entire vehicle in an FEA environment, it could take weeks to finish even one simulation [1]. and it contains about 250 DOFs (Degrees of Freedom), with 13 subsystems. There are 14 interaction points between the MBD and the FEA model, and 14 MARKERs and GFORCEs were defined in the Adams Car templates to communicate with the Marc model. The BMW Chassis underbody was modeled in the Marc environment (Figure 4), with 11...

Open the catalog to page 12All MSC SOFTWARE - HEXAGON MANUFACTURING INTELLIGENCE catalogs and technical brochures

-

Corporate Presentation

41 Pages

-

Annual Report 2022

88 Pages

-

Sustainability Report 2022

58 Pages

Archived catalogs

-

Simufact Welding

8 Pages

-

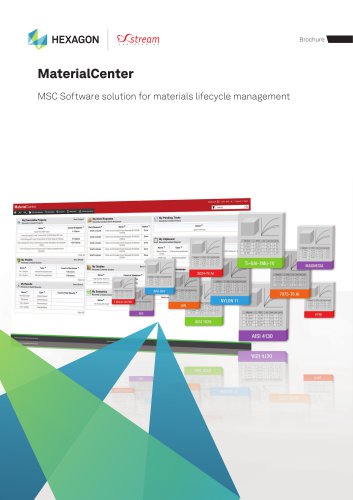

MaterialCenter Brochure

12 Pages

-

ODYSSEE (CADLM)

5 Pages

-

Sustainability

92 Pages

-

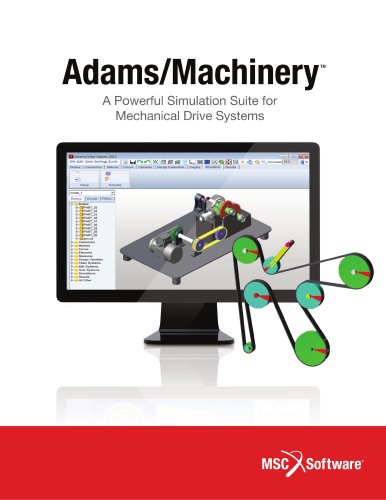

Adams/Machinery

12 Pages

-

Actran

12 Pages