Catalog excerpts

Romax drives Hexagon | MSC Software into eMobility Delivering solutions for the next generation of electric drivetrains With industry-leading simulation software and a wealth of engineering expertise, Romax Technology is at the forefront of the acceleration into electrification. • Expertise: Over 30 years’ experience in rotating machinery engineering and simulation, supplying the automotive, aerospace and bearing industries. • Software: An integrated suite of multi-physics and multi-fidelity software applications driving the next generation of quiet, efficient and durable powertrain...

Open the catalog to page 2

Forensic investigations of falls using Adams Metal 3D How reducing heat distortion during additive manufacturing results in better tyre tread moulds eMobility Commentary On a mission to engineer a more sustainable world SmartUQ Quantifying simulation model uncertainties: the MSC Software and SmartUQ approach AI/ML Commentary AI & machine learning will transform CAE simulation and deliver usable digital twins Marshall Aerospace Marshall Aerospace & Defence Group address COVID-19 crisis by re-designing the iron lung ventilator using MSC Apex From bearings to eMobility with Romax Technology...

Open the catalog to page 3

From bearings to eMobility with Romax Technology Dr. Peter Poon, MBE, founder of Romax Technology Engineering Reality Magazine recently interviewed Dr. Peter (Siu Yun) Poon, MBE, founder of Romax Technology, which became part of Hexagon | MSC Software in June 2020. Still going strong as he approaches his ninth decade, Romax was based on his vision to engineer a better world through the power of computer simulation, and stems from his deep-rooted passion for engineering and desire to improve the future of rotating machinery. Born in China, he came from Hong Kong to Britain in 1962 where he...

Open the catalog to page 4

the time and needless to say they are expensive to build and maintain. Getting the design time down and right first time is therefore critical. When we applied the Romax philosophy to these gearboxes we got the design cycle time down from 36 months to 9 months including prototyping. Q. Electrification is coming, where does Romax solutions fit in to the mix? implications. This is where CAE has such a high return-on-investment. If you design your product right in the first place you will have reduced your manufacturing costs dramatically. Q. Tell us about Romax’s foray into Wind Turbine...

Open the catalog to page 5

Romax software drives more focused, streamlined and lowcost development of innovative products Client Leading Korea-based Automotive parts and machine tools business; total annual revenues of more than US $8 billion. Solution Romax Concept software for initial design stage investigations, and other Romax products for further, detailed simulation of the gearbox model. Challenge More quickly and accurately design and develop multiple products in broadly similar areas (e.g. drivetrain) but with highly different requirements/ end users, meaning varying technical targets and development goals....

Open the catalog to page 6

Right first time Lee says Romax Concept enables a more streamlined and compact development loop: “It helps decrease development time and helps in minimising design failure. Through a smaller development cycle we can make products more robust at an earlier stage - using Romax enables us to overcome limitations we might face, as well as meeting Right First Time design requirements.” The benefits of an enhanced design capability early in the process are clear: “It relates to the cost effect,” Lee adds. “With Design For Six Sigma (DFSS) and the Six Sigma process improvement approach, most...

Open the catalog to page 7

Romax consulting and software supports GKN Driveline to design low-noise high-efficiency eDrive gearboxes The evolution of electric vehicles (EVs) and hybrid electric vehicles (HEVs) is having a significant impact on Automotive engineering, particularly transmission and driveline design. The world’s leading manufacturer of Automotive driveline components, GKN Driveline has applied Romax software and consulting to focus the optimization of gearbox efficiency in electric motor-driven transmission without accepting trade-offs in noise and durability. Client The world’s leading manufacturer of...

Open the catalog to page 8

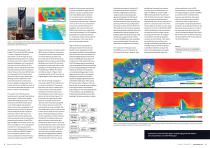

Assessing wind turbines in Korean skyscrapers with Cradle CFD By Jonas Wirgart, PMM Cradle CFD The world’s tallest artificial structure is the 829.8-metre-tall (2,722 ft) Burj Khalifa in Dubai in the United Arab Emirates and like most such buildings it exists in densely populated urban areas. This has an impact in terms of wind patterns produced around the building and its environmental impact locally. However, such tall buildings also pose an opportunity for planners and designers to potentially rethink designs to take into account sustainability concerns with respect to generating...

Open the catalog to page 9

Figure 2. The Strata SE1 Apartment flow analysis: (a) photo from the rear of the wind turbines; and (b) contour plot of wind speed on a horizontal cross-sectional plane (top) and streamlines passing through holes (bottom; CFD by the authors). Another fluid flow analysis using Cradle CFD of the Strata SE1 building in London, England, and built in 2011, which is a 148 m-high, 43-story residential building with three rooftop horizontal-axis wind turbines of 19 kW capacity integrated into the building was also carried out (Figure 2). The building is iconic looking and has been awarded several...

Open the catalog to page 10

CAE efficiency improvement with automatic simulation platform By Dr. Qianqian Chen & Qiuyi Wei, CAE technology development department, CHANGAN Automobile “Automatic Simulation Platform (ASP) allows us to reduce 30% CAE validation time in vehicle development cycle.” Under the pressure of joint venture’s MSRP reduction and increasing brand of local automobile enterprise in China, Changan Automobile proposed a 24-month vehicle development cycle to fit the environment. CAE validation almost covers three quarters of the process in the development cycle, which mean the analysis efficiency becomes...

Open the catalog to page 11All MSC SOFTWARE - HEXAGON MANUFACTURING INTELLIGENCE catalogs and technical brochures

-

Corporate Presentation

41 Pages

-

Annual Report 2022

88 Pages

-

Sustainability Report 2022

58 Pages

Archived catalogs

-

Simufact Welding

8 Pages

-

MaterialCenter Brochure

12 Pages

-

ODYSSEE (CADLM)

5 Pages

-

CO-SIMULATION

92 Pages

-

Sustainability

92 Pages

-

Adams/Machinery

12 Pages

-

Actran

12 Pages