Catalog excerpts

High Pressure filters Maximum pressure up to 320 bar - Flow rate up to 475 l/min High Pressure filters

Open the catalog to page 1

FILTER SIZING Corrective factor FILTER SIZING Corrective factor The correct filter sizing have to be based on the variable pressure drop depending by the application. For example, for the return filter the pressure drop have to be in the range 0.4 - 0.6 bar. Corrective factor Y, to be used for the filter element pressure drop calculation. The values depend to the filter size and lenght and to the filter media. Reference viscosity 30 mm2/s The pressure drop calculation is performed by adding together the value of the housing with the value of the filter element. The pressure drop in the...

Open the catalog to page 2

Corrective factor FILTER SIZING Corrective factor Y, to be used for the filter element pressure drop calculation. The values depend to the filter size and lenght and to the filter media. Reference viscosity 30 mm2/s Suction filters Low & Medium pressure filters Filter element Return / Suction filters Filter element Filter element

Open the catalog to page 3

Corrective factor Y, to be used for the filter element pressure drop calculation. The values depend to the filter size and lenght and to the filter media. Reference viscosity 30 mm2/s Stainless steel high pressure filters Filter elemen Filter element Filter element Filter element

Open the catalog to page 4

Selection Software FILTER SIZING Step Select “FILTERS” Choose filter group (Return Filter, Pressure Filter, etc.) Choose filter type (MPF, MPT, etc.) in function of the max working pressure and the max flow rate Push “PROCEED” Insert all application data to calculate the filter size following the sequence: - working pressure - working flow rate - working pressure drop - working temperature - fluid material and fluid type - filtration media - connection type Push “CALCULATE” to have result; in case of any mistake, the system will advice which parameter is out of range to allow to...

Open the catalog to page 5

High Pressure filters

Open the catalog to page 6

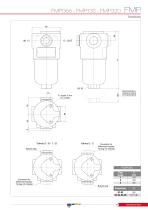

High Pressure filters Maximum pressure up to 320 bar - Flow rate up to 475 l/min High Pressure filters

Open the catalog to page 7

Technical data High Pressure filters Maximum pressure up to 320 bar - Flow rate up to 475 l/min Filter housing materials - Head: Phosphatized cast iron - Housing: Phosphatized steel - Bypass valve: Brass - Reverse Flow: Steel (only for series FMP 320) - Check valve: Steel Pressure - Working pressure: 32 MPa (320 bar) - Test pressure: 48 MPa (480 bar) - Burst pressure: 96 MPa (960 bar) - Pulse pressure fatigue test: 1 000 000 cycles with pressure from 0 to 32 MPa (320 bar) Bypass valve - Opening pressure 600 kPa (6 bar) - Other opening pressures on request. Seals - Standard NBR series A -...

Open the catalog to page 8

Check Valve GENERAL INFORMATION Valves Pressure drop The curves are plotted using mineral oil with density of 0.86 kg/dm3 in compliance with ISO 3968. Bypass valve pressure drop ∆p varies proportionally with density. 0.00 0 Bypass valve pressure drop 15 Flow rate l/min 10 Filter housings ∆p pressure drop 10 Δp bar Check Valve Check Valve Flow rate l/min Flow rate l/min Check Valve Valves Bypass valve pressure drop Bypass valve pressure drop Flow rate l/min 15 FMP 320 150 100 Flow rate l/min Flow rate l/min 200 Check Valve Flow rate l/min 400 Flow rate l/min 150 72 200 Flow Flow l/min l/min...

Open the catalog to page 9

E Without bypass, plug on the opposite side B With bypass 6 bar C With bypass 6 bar, plug on the opposite side T With check valve, without bypass D With check valve, with bypass P02 Maintenance from the bottom of the housing Pxx Customized Filter length Differential indicators DEA Electrical differential indicator DTA Electronic differential indicator DEM Electrical differential indicator DVA Visual differential indicator DLA Electrical / visual differential indicator DVM Visual differential indicator DLE Electrical / visual differential indicator Additional features

Open the catalog to page 10

Recommended clearance space for maintenance High Pressure filters

Open the catalog to page 11

High Pressure filters

Open the catalog to page 12

High Pressure filters

Open the catalog to page 13

High Pressure filters

Open the catalog to page 14All MP Filtri catalogs and technical brochures

-

MULTI-COMPONENTS

31 Pages

-

LMS/LDS Series

17 Pages

-

LMC/LDC Series

17 Pages

-

LMG Series

21 Pages

-

ACCESSORIES

28 Pages

-

BELL HOUSING

72 Pages

-

CLOGGING INDICATORS

24 Pages

-

COUPLINGS

46 Pages

-

CONTAMINATION CONTROL SOLUTIONS

140 Pages

-

Return / Suction Filters

76 Pages

-

SPIN-ON FILTERS

76 Pages

-

Stainless Steel Filters

102 Pages

-

Low & Medium Pressure Filters

168 Pages

-

High Pressure Filters

160 Pages

-

Suction Filters

72 Pages

-

Return Filters

230 Pages

-

FHD - DUPLEX

17 Pages

-

FHF 325 - MANIFOLD

14 Pages

-

FHB - MANIFOLD

16 Pages

-

FHM - MANIFOLD

21 Pages

-

FHP

19 Pages

-

Spin-On Filter

78 Pages

-

Stainless Steel

20 Pages

-

LMP 124

6 Pages

-

MRSX

12 Pages

-

MSH

4 Pages

-

CS - CG - CW - CT

2 Pages

-

MPS

8 Pages

-

LMP 952 - 954

6 Pages

-

LMP 900 - 901

4 Pages

-

LMD 400 - 401 - 431 DUPLEX

8 Pages

-

LMP MULTIPORT

8 Pages

-

FMM 050 - FHA 051

6 Pages

-

FMP 039

4 Pages

-

Clogging Indicators

26 Pages

-

SF2 250 - 350

4 Pages

-

Suction Strainer

7 Pages

-

FRI

10 Pages

-

MPI

8 Pages

-

MPH

18 Pages

-

MPT

15 Pages

-

filter element CH

1 Pages

-

MST

4 Pages

-

STR

4 Pages

-

RF2

4 Pages

-

MPF

20 Pages

-

LMP 400 - 430

10 Pages

-

LMP 210

5 Pages

-

LMP 110-120-123 MULTIPORT

25 Pages

-

FAS

4 Pages

-

SF2 500

12 Pages

-

SF2 250

8 Pages

-

Structural components

78 Pages

-

SA - SAP

10 Pages

-

STR

4 Pages

-

Condition monitoring products

14 Pages

-

Pressure filters

116 Pages

-

In-line filters

108 Pages

-

Structural components

64 Pages

-

Accessories

68 Pages

-

Catalogue

19 Pages