Catalog excerpts

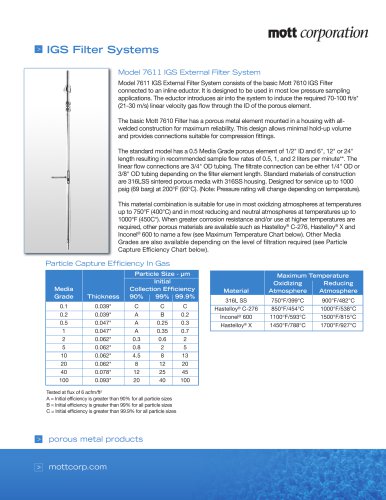

IGS Filter Systems Model 7611 IGS External Filter System Model 7611 IGS External Filter System consists of the basic Mott 7610 IGS Filter connected to an inline eductor. It is designed to be used in most low pressure sampling applications. The eductor introduces air into the system to induce the required 70-100 ft/s* (21-30 m/s) linear velocity gas flow through the ID of the porous element. The basic Mott 7610 Filter has a porous metal element mounted in a housing with allwelded construction for maximum reliability. This design allows minimal hold-up volume and provides connections suitable for compression fittings. The standard model has a 0.5 Media Grade porous element of 1/2" ID and 6", 12" or 24" length resulting in recommended sample flow rates of 0.5, 1, and 2 liters per minute**. The linear flow connections are 3/4" OD tubing. The filtrate connection can be either 1/4" OD or 3/8" OD tubing depending on the filter element length. Standard materials of construction are 316LSS sintered porous media with 316SS housing. Designed for service up to 1000 psig (69 barg) at 200°F (93°C). (Note: Pressure rating will change depending on temperature). This material combination is suitable for use in most oxidizing atmospheres at temperatures up to 750°F (400°C) and in most reducing and neutral atmospheres at temperatures up to 1000°F (450C°). When greater corrosion resistance and/or use at higher temperatures are required, other porous materials are available such as Hastelloy® C-276, Hastelloy® X and Inconel® 600 to name a few (see Maximum Temperature Chart below). Other Media Grades are also available depending on the level of filtration required (see Particle Capture Efficiency Chart below). Particle Capture Efficiency In Gas Media Grade Particle Size - µm Initial Collection Efficiency 90% 99% 99.9% C A A A 0.3 0.8 4.5 8 12 20 Tested at flux of 6 acfm/ft2 A = Initial efficiency is greater than 90% for all particle sizes B = Initial efficiency is greater than 99% for all particle sizes C = Initial efficiency is greater than 99.9% for all particle sizes Material 316L SS Hastelloy® C-276 Inconel® 600 Hastelloy® X Maximum Temperature Oxidizing Reducing Atmosphere Atmosphere 750°F/399°C 850°F/454°C 1100°F/593°C 1450°F/788°C

Open the catalog to page 1

Model 7612 Flange Mounted In-Stack IGS Filter System INSTALLATION CLEARANCE (SPECIFY – 4 MIN) 3/8" EDUCTOR INLET 3/8" SAMPLE LINE TO ANALYZER FLANGE FACE Model 7612 Flange Mounted In-Stack IGS Filter System is designed to allow placement of the IGS filter inside a stack or pipe, without risk of fouling the filter element. It consists of the basic Mott 7611 IGS Filter GAS SAMPLING POINT System (filter and eductor) mounted on a rigid support structure. In-stack systems are often chosen because of external space limitations, or because an external system would drop the gas temperature below...

Open the catalog to page 2All Mott catalogs and technical brochures

-

Additive Manufacturing Overview

12 Pages

Archived catalogs

-

Series 6610

1 Pages

-

Series 850

1 Pages

-

Steam Filters

2 Pages

-

Static flow controller sfc

2 Pages

-

Mott HyPulse® LSI Filters

2 Pages

-

High Purity Products

2 Pages

-

GasShield® Diffuser

4 Pages

-

Porous Metal Solutions

8 Pages

-

Polymer PolyPak Filters

1 Pages

-

Flame Arrestors

2 Pages

-

Air Film Rolls

8 Pages

-

Biotech Applications

1 Pages

-

Inertial Gas Sampling Filters

12 Pages

-

Process Systems Overview

12 Pages

-

Lab Testing Filters

8 Pages

-

Filter Elements Brochure

12 Pages

-

Catalyst Recovery Filters

8 Pages

-

Utility & Bulk Filters

4 Pages

-

Sentry Nickel Gas Filters

2 Pages

-

POU Filters

4 Pages

-

PENTA® Nickel Gas Filters

8 Pages

-

IGS Filters & Restrictors

8 Pages

-

GasketFilters

2 Pages

-

Flow Restrictors

4 Pages

-

Diffusers

4 Pages

-

Defender Fiber Gas Filters

2 Pages

-

Biotech Steam Filters

2 Pages

-

Biotech Filter Housings

4 Pages

-

Corporate Overview

8 Pages

-

Fiber metal gas filtration

8 Pages

-

Porous metal solutions

16 Pages

-

Porous metal filter elements

12 Pages

-

Mott Corporation Spargers

8 Pages